Several industries use microwave drying as a sophisticated process to help reduce moisture in products. This method differs from conventional drying methods, often based on convective heat transfer, since it uses electromagnetic radiation that causes water molecules within the material to vibrate. As a result, internal heating helps with the quick and even drying of the substance. It is because of its efficiency compared to traditional ways that it is more applicable in various sectors like food processing, medicine manufacturing, and ceramics. This blog aims to look into the basic principles of microwave drying and analyze its pros and cons while considering various cases where it can be applied.

Understanding Microwave Drying

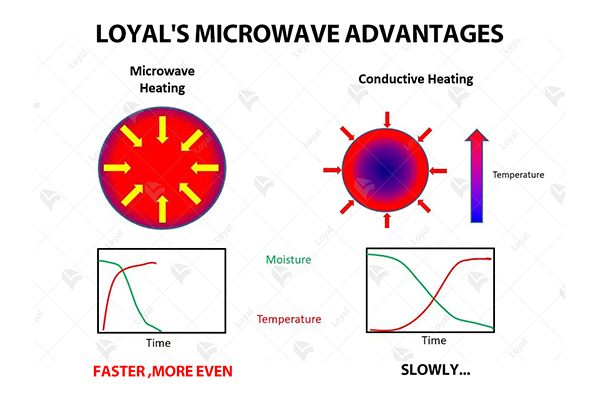

Microwave drying is based on the principle of dielectric heating, whereby polarized molecules such as water are disturbed by various electromagnetic fields created by microwaves. This impact causes friction, which then heats up the material and, therefore, vaporizes its wetness. Because of this, it can be said that during microwave drying, there is global and quick interaction between microwaves and water molecules, thus avoiding thermal gradients that lead to non-uniform drying or destruction of goods. It should be noted that this method is distinguished from traditional drying methods, where materials are heated at the surface, and conduction is used to convey heat inwardly. Hence, microwave drying consumes less energy resources in comparison with conventional methods, hence preserves the quality and integrity of thermosensitive substances.

How does microwave drying work?

Microwave drying works by subjecting the material to an electromagnetic field with frequencies typically ranging from 300 MHz to 30 GHz. The most commonly used frequency for industrial microwave drying is 2450 MHz. As microwaves penetrate the material, they interact with polar molecules, primarily water, causing them to oscillate at high speeds. This rapid oscillation generates frictional heat, resulting in the evaporation of moisture from within the material.

- Frequency: Standard for industrial applications is 2450 MHz as it optimizes energy absorption into water.

- Power Density: Their typical range lies between 0.1-1.0 W/cm³ thereby affecting both the rate of drying and efficacy consumed.

- Penetration Depth: The range depends on frequency and moisture content; water-rich objects can have a penetration depth of approximately one to three centimeters at 2450 MHz.

- Temperature Control: preventing damage due to overheating of temperature-sensitive products; about 50-150 °C depending on materials usually might be called acceptable temperatures.

Is microwave drying suitable for all materials?

On account of different interactions between microwaves and diverse substances used in some cases but not others, microwave drying is not universally applicable. The primary factor that determines the suitability of materials for microwave drying is their dielectric properties, which determine the ability of a given material to absorb and convert microwave energy into heat. These are organic materials like foodstuffs, textiles, or certain pharmaceuticals that have high levels of moisture content and may permit appropriate dielectric constants.

For optimal drying, key technical parameters need to be meticulously managed:

- Dielectric Constant: Microwave energy can be absorbed efficiently in substances with high di-electric constant values only.

- Thermal Stability: Materials must withstand the heat without degradation; sensitive materials may require precise temperature control, generally between 50-150°C.

- Moisture Content: High moisture materials benefit most from microwave drying, given the rapid internal heating.

- Penetration Depth: This means that it is effective only at very limited depths (approximately 1 to 3 cm for water-rich material at 2450 MHz) making the technology unsuitable for thin or evenly distributed samples.

- Power Density: Must be adjusted (0.1 to 1.0 W/cm³) to balance energy efficiency and prevent overheating.

In summary, while microwave drying excels for water-rich organic materials that are thermally stable; it works poorly on the other hand when applied to those with low moisture contents on low di electric constant values or any thermosensitive case.

What Are the Advantages of Microwave Drying?

Microwave drying presents several advantages that it possesses over conventional drying methods. Microwaves can dry internally rather than from outside in and in fact, this is how microwave drying works. In addition, microwave drying operates at lower temperatures than other drying methods, which helps preserve the organoleptic properties of heat-sensitive materials. Microwave energy is directly converted into heat within material instead of using external heat sources; therefore, it has a higher energy efficiency. These advantages are crucial in improving productivity, quality and cost-effectiveness in various industrial applications.

Enhancement Of Efficiency And Speed Of Drying Through The Use Of Microwave

Microwave drying is known for its exceptional efficiency and rapid processing speed, standing out notably when compared to conventional drying methods. Energy introduced through microwaves penetrates deeper into the material and more uniformly throughout the substance, reducing overall drying time significantly. Thus, for example, research demonstrates that microwave drying may be four or ten times faster than traditional hot air drying.

Technical parameters are crucial for optimizing microwave-drying processes.

- Frequency: For instance, commonly utilized frequencies for microwave heating include 915 MHz (megahertz) and 2450 MHz with the former being more suitable for larger samples as compared to finer ones because of having greater wavelength lengths.

- Power Density: Consequently, power densities must be adjusted; common power densities have varied from about 0.1 W/cm³ to 1 W/cm³ so as not to be too low or too high, rendering them inefficient or degrading the quality of products.

- Penetration Depth: Typically limited by water content penetration depth often ranges between one to three centimeters at 2450 MHz frequency affecting uniformity’s extent in bulkier samples.

- Temperature Control: Further, effective use of temperature while ensuring that material qualities are saved during fast evaporation requires maintaining temperatures at around 30°C-125°C.

By manipulating these parameters effectively, microwave drying enables not only rapid drying but also improved power efficiency, reduced operating costs, and retention of important material attributes that make it a preferable choice in many industrial applications.

Improved Uniform Drying

Sample configuration is one of the most important factors affecting uniform drying in a microwave. The energy distribution consistency depends on the uniformity of thickness and shape. Several leading sources have found that a uniform sample thickness, typically between 1 and 2 cm, is necessary for homogenous drying. In addition, rotating samples during processing can promote even energy absorption throughout.

Control over Dielectric Properties is another requirement to make the most of effective microwave-drying capabilities where other forms are utilized. As frequency-dependent properties, these considerations may lead to better uniformity when selecting an optimal frequency. Some materials with higher dielectric constants may dry more uniformly at lower frequencies while others may require higher frequencies for better energy penetration and heating.

Integration of hybrid systems is another critical factor. This means combining conventional methods such as convective hot air with microwave energy to offset some limitations associated with microwaves as a sole drying mechanism. The speedup internal heating caused by microwaves, coupled with the surface evaporation capacity from hot air drying, makes this hybrid approach result in more uniformly dried products.

Regarding enhancing uniform drying these are key technical parameters:

- Sample Thickness: Ideally, uniformly thick (1-2 cm) samples are desired.

- Sample Rotation: Regularly rotate during the drying process.

- Frequency Selection: Matching material dielectric properties with optimum frequency.

- Hybrid System Integration: Combination of microwave and convective drying methods.

These strategies are a holistic approach to uniform drying, supported by microwaves’ accurate control of microwave parameters.

Retention of Nutrients in Food Products

Nutrient retention in food products during drying processes is multifaceted and interacts with various technical parameters. According to well-respected sources, keeping temperature, drying time, and method of dying under careful control is a prerequisite for keeping vitamins, minerals, antioxidants, and other nutrients in a dried product.

Microwave can also minimize nutrient degradation when it is optimized. Internal heating by microwave energy reduces drying time, thereby protecting thermolabile types of vitamins. For maximum nutrient retention, the highest temperature used for drying should be 60°C. Maintaining lower temperatures will prevent thermal degradation of vitamins, including vitamin C and B vitamins, which are highly heat sensitive and therefore, might result in less loss in nutritional value as possible.

The dielectric properties for food materials also play an outstanding role on nutrient retention. Foods with high water content absorb more microwave energy, hence their shorter dry times and low nutrient losses during the dying process. Microwave frequencies used must match those particular to the food’s dielectric properties so as to enable consistent heating and minimal nutrient loss throughout all its parts. Frequencies around 2.45 GHz are typical for domestic microwave ovens and have been found suitable for many food product varieties, according to experiments.

In hybrid systems combining convective hot air with microwave energy, regulated air temperatures create additional nutrient protection. By using the hybrid system, it is possible to achieve a combination of surface and internal heating, thus reducing oxidative damage that leads to the most common types of nutrient loss during drying. To optimize nutrient retention in hybrid systems, one has to ensure that the air temperature never exceeds 80°C and that microwaves are not overheated.

Technical Parameters for Optimal Nutrient Retention:

- Drying Temperature: Keep below 60°C.

- Microwave Frequency: Typically around 2.45 GHz, matching the dielectric properties of food.

- Air Temperature in Hybrid Systems: Maintain below 80°C.

- Drying Time: Minimize to reduce exposure of nutrients to heat.

- Power Regulation: Fine-tune microwave power to prevent overheating.

These parameters ensure that nutritional integrity is maintained during drying, thereby ensuring that the end product is safe and nutritious.

How Does the Microwave Drying Process Compare to Traditional Methods?

A comparison of microwave drying with conventional drying methods reveals several important differences. Traditional drying methods like air-drying, freeze-drying and sun drying operate on low temperatures for long times which leads to longer processing time and high energy consumption. With traditional air drying, heat and mass transfer occur through convection and conduction resulting in uneven drying as well as potential quality deterioration that comes from prolonged exposure to oxygen and heat.

The reason is that microwaves directly heat up the water molecules within food products, resulting in much faster dehydration processes. This increases the overall process’s speed, lowering global energy expenditure. Microwave drying is also known for providing more even drying because it can be localized specifically to water content, thus most effectively preserving tissue structure and nutritionally valuable constituents in food products.

However, there are some potential issues related to microwave drying because operating at inappropriate power or frequency settings may result in localized overheating leading to such problems as nutrient loss, flavor changes or texture modifications. Consequently, optimum parameters, including proper levels of microwave power as well as matching food’s dielectric properties with a given microwave frequency, should be set during operation in order to achieve the best performance.

It is possible to mitigate these drawbacks by managing the microwave dryers with care making them better ways of achieving higher efficiency compared to previous procedures with improved nutrition values.

Comparison between Microwave Drying and Hot Air Drying

Drying Time: It has been observed that when materials are dried using microwaves they take very minimal time unlike those dried using hot air where they need long period of time. Thus, microwaves target water molecules directly inside materials thereby causing faster evaporation. On the other hand convective heat transfer on hot air carries out this process slowly hence it is less effective than others.

Energy Efficiency: In general, microwave drying is more energy efficient. its energy consumption during drying is 30-50% less than conventional hot air drying. Microwaves also convert electromagnetic energy into thermal energy in the food, thus reducing losses of this type.

Quality of Final Product:

- Nutritional Value: Research suggests that microwave drying retains more nutrients as opposed to hot air methods. An example is the work that revealed that vitamins and antioxidants are better conserved through this method compared to other approaches.

- Texture and Colour: Microwave drying can better preserve food texture and color. Quick dehydration using microwaves reduces temperature exposure time, resulting in less Maillard reaction involved in appearance changes or textural modifications induced by high temperatures.

Technical Parameters

- Microwave Power and Frequency: The typical output power levels fall between 500W and 1000W, while a frequency of 2450 MHz is common for most applications. These settings ensure efficient energy transfer and prevent localized overheating.

- Airflow Temperature for Hot Air Drying: This normally ranges from 50°C and 80°C depending on the moisture content as well as thermosensitivity exhibited by the product under consideration. Proper airflow control and accurate temperature management are essential to achieving uniformity in the drying process.

In summary, microwave drying has faster processing times, better energy use and nutritional and aromatic preservation than hot air drying methods. It is therefore important that the microwave power and frequency be properly calibrated so as to maximize these benefits while reducing their drawbacks.

Microwave Drying Efficiency versus Convective Drying

Drying time, energy consumption and product quality are key factors when assessing microwave drying efficiency against convective drying. Concerning this, based on a quick heating mechanism that focuses on water molecules within items directly, it is noted that the microwave-drying method usually takes a significantly shorter period to dry compared to convective methods. Microwave drying can reduce processing time by 50-60% compared to convective means.

The amount of energy consumed is generaly lower in case of Microwave drying.This is due to direct energy transfer from Microwaves into water molecules, resulting in reduced wastage of energy, unlike the situation with Convective Drying, which increases temperature gradually through hot air, leading to higher overall costs. Research findings have shown that under favorable conditions, about 30-40% of energy saving can be achieved through Microwave drying.

Microwave-dried products retain more nutrients and flavors since they are subjected to shorter periods at high temperatures, thereby minimizing thermal degradation. On the other hand, convective driers involve longer durations at much higher temperatures, often causing significant changes in the composition and external appearance.

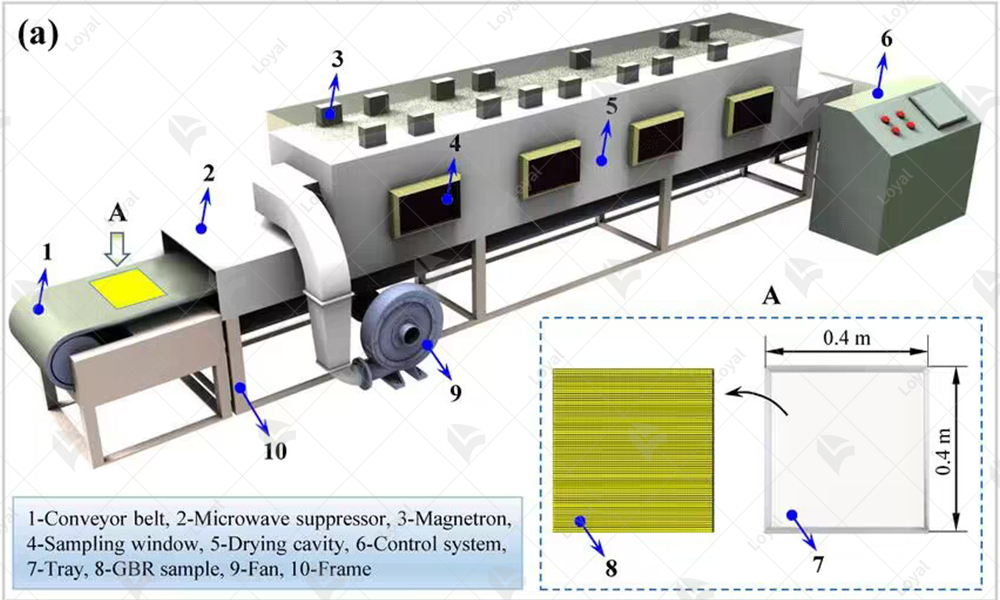

What are the Key Components of a Microwave Drying System?

Essential to the successful operation of a normal microwave drying system are several principal constituents, one being a microwave generator, often referred to as magnetron, whose function is to convert electrical power into microwave energy. The other major component is the waveguide which transports microwaves from the magnetron into the drying chamber where the product has been placed. To ensure even distribution of microwaves and optimized interaction with product, such a drying chamber may include rotating platforms for uniform exposure. Not only that, but sensors and feedback in the control unit also help regulate and keep an eye on microwave power before drying exactly takes place. There must be efficient exhaust as well as ventilation systems that assist in vapor management and maintaining appropriate drying environment. Lastly, safety interlocks as well as shielding materials are used to prevent leakage of microwaves, thus protecting operators.

How do industrial microwave systems work?

Industrial microwave systems work by creating microwaves using magnetrons or microwave generators which are then directed at a chamber housing the material to be dried. The material takes up these waves and polar molecules within its structure start oscillating hence producing heat. This leads to moisture removal from within.

- Microwave Frequency: Typically, industrial microwave systems use a frequency of 2450 MHz, which is optimal for efficient heating.

- Power Levels: Power levels vary by application and system capacity, generally ranging from 1 kW to several hundred kW. Proper power calibration is crucial to avoid overheating and ensure energy efficiency.

- Drying Time depends significantly on both power level and moisture content of the material in question; therefore, this technique can potentially reduce drying time by 50% or more compared to traditional methods.

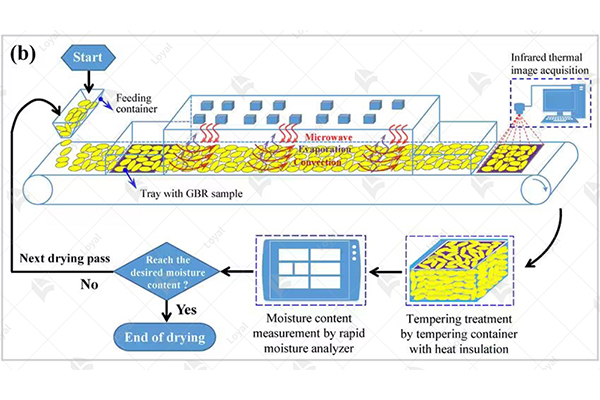

Additional components such as waveguides, mode stirrers, and conveyor systems ensure uniform distribution and efficient processing. Waveguides direct microwaves towards specific directions while mode stirrers distribute them uniformly hence leading to even heating. Conveyors are used to ensure that there is constant material flow through the drying chamber thereby improving the throughput and efficiency. All these are technical considerations and parameters that enable industrial microwave systems to provide a high level of control, short processing times and better product quality.

Understanding the role of microwave in drying

Microwave drying works on a dielectric heating principle where microwaves penetrate materials, hence causing polar molecules within the product, majorly water, to oscillate. This oscillation results in molecular friction, which then generates internal heat, leading to fast evaporation of moisture. Unlike such convective drying that depends on surface heating followed by conduction inward, microwave drying is effective because it can evenly heat the entire product volume. The technical parameters involved in the process include the microwave frequency (commonly 2450 MHz for industrial applications), power levels (measured in kilowatts, with typical ranges from 1 kW to several hundred kW), and drying time, which is significantly reduced compared to conventional methods. These parameters must be carefully controlled to prevent thermal runaway and ensure uniform drying. Microwave drying systems achieve high throughput, energy efficiency, and enhanced product quality through this leverage of principles and parameters, as opposed to traditional dryers, which can never strive for similar benefits.

What is the need for drying time in a microwave dryer?

The importance of drying time in a microwave dryer cannot be overemphasized because it directly affects the efficiency, energy consumption and end product quality. Accurate drying time ensures that the material reaches the targeted moisture content without being either over or under-dried. Too much drying time can result in the degradation of material properties, while insufficiently dried material may retain moisture, which influences storage stability and the utilization of materials.

Material Moisture Content: The initial moisture content determines how long it will take to dry. Higher levels of moisture require longer drying durations.

- Microwave Power Level: High power levels reduce the drying time but must be accurately adjusted to avoid hot spots and ensure uniformity during drying.

- Material Thickness and Density: Microwaves take more time to penetrate and evenly heat through thicker and denser materials thus they require longer periods during which they are dried.

- Drying Temperature: It’s important to maintain an optimal temperature that can prevent the degradation of delicate materials while ensuring sufficient moisture evaporation.

Why is Microwave Drying Used in the Food Industry?

Microwave drying is utilized in the food industry due to its many advantages over traditional drying methods. Microwave drying for instance, reduces drying times by directly heating the food’s water molecules leading to faster evaporation of moisture. This rapid process reduces prolonged exposure to high temperatures hence preserving nutritional quality and sensory attributes of food products at a minimum. The technique also ensures that there are no hotspots through uniform drying, therefore maintaining the product’s quality uniformly. Due to this, it consumes less power as it mainly focuses on moisture content not necessarily heating the surrounding air or equipment excessively thus reducing energy consumption. Moreover, water activity decreases more quickly when microwave drying is applied to foods as a way of promoting microbial safety which can prevent pathogens’ growth and spoilage organisms leading to an extended shelf-life.

The use of microwave treatment in fruits and vegetables

The nutritional value, color, and flavor of fruits and vegetables are well preserved during this process since moisture content can be rapidly reduced through direct interaction between microwaves and water molecules thereby minimizing thermal damage. Furthermore, compared with traditional techniques, microwave drying significantly decreases the amount of time needed for drying while retaining thermo-sensitive vitamins and antioxidants intact. It has been found that various researchers have shown microwave-dried fruits to have undergone even dehydration so that they do not become unevenly dry and possibly spoiled. Additionally, this method saves energy by focusing on only the liquid percentage without raising room temperature considerably or getting equipment hotter; it creates a situation whereby power consumption is greatly reduced thus saving more money on bills too. Finally by quickly reducing moisture content within them microorganisms cannot get enough water needed for their survival causing decay course.

How does microwave treatment affect food products?

Microwave treatment influences several aspects in food products either independently or collectively resulting into changes in their physical properties as well as other characteristics affecting their nutritive value in general terms; including thermal effects as well as non-thermal ones combined together for the latter. Among these, microwaves produce even and rapid heating, which minimizes the thermal degradation of heat-sensitive nutrients like vitamins and antioxidants. It is because they are exposed to high temperatures for a shorter time.

When microwaves are directed at food, water molecules move, causing vibrations, which generate heat. Instead of heating only the exterior portion associated with traditional processes, this internal heating can give rise to more uniform drying or cooking. Microwave energy absorption by dielectric properties of foods depends largely on their moisture content, too. Foods with higher moisture absorb microwaves more efficiently, leading to faster processing times.

As far as microbiology is concerned, microwave effects help reduce microbial numbers especially those which result from the thermal effects and fast heating. This water reduction also retards spoilage organisms and pathogens growth, thus enhancing the safety and shelf life periods of such products. It has been found in various studies that optimal microwave parameters, including power level and exposure time, can be applied differently based on the type of food being processed or achieved goal desired. For example, microwave power levels range from 500-1500 watts, whereas the time depends on its moistness coupled with what quality attribute one is looking forward to achieving after all.

Microwave treatment can be advantageous or disadvantageous regarding food texture depending on the characteristics sought. For example, when fruits and vegetables are microwaved, they become less dry, and their firmness is better maintained compared to air-drying or oven-drying methods. However, if the microwave is overused it may result in excessive drying and thus loss of texture thereby necessitating strict control over processing conditions.

In general, the use of microwave energy in a very efficient and controlled manner has great impacts on food processing by improving nutritional quality, microbial safety, and energy consumption.

What are the benefits of using microwave drying for foods?

Over its few strong advantages, its quick rates of desiccation as well as its low power consumption are two most notable reasons why microwave drying is believed to stand out among other methods available. According to the best sources, microwave drying reduces processing time significantly compared to traditional drying methods since it heats water directly within the food. This causes internal heating that results into fast moisture evaporation hence promoting flow capacity and speed. As such, this can reduce time spent on this process by approximately fifty percent which means more nutrients will remain intact especially in those products which are highly susceptible to heat degradation.

Moreover, microwave drying improves control over the final product’s quality. The technology protects against high-temperature damage by helping maintain original coloration while maintaining nutritional content and smooth texture. Studies indicate that vitamin C levels are retained more in microwaved dried materials because of the shorter period of reduction.

Energy efficiency stands out as another critical parameter where microwave drying prevails over conventional ones that require longer time for heating since microwaves target only water molecules. Generally speaking specific energy consumption of a microwave dryer ranges between 1-3 kWh/kg water removed which is much lower than hot air dryer used today.

Technical parameters like power levels and exposure times play an important role in optimizing the microwave drying process. Power levels are typically set between 500 and 2000 watts, while exposure times depend on the initial moisture content of the food and its type. It is important to strike a balance between power input and drying time to not make food too dry or lose its texture.

In conclusion, some key advantages of microwave drying for food products are prompt drying rates, improved product quality, increased nutrient preservation as well as greater energy efficiency making it an efficient modern food processing technique.

Challenges and Solutions in Industrial Microwave Drying

Nonetheless, one of the primary challenges that have been faced by industrial microwave drying is non-uniform heating. This can lead to uneven moisture distribution and consequently, over-drying or under-drying different product parts. In response to this, advanced control systems as well as turntables or stirrers are being used to ensure better homogeneous heating. Furthermore, integrating thermal imaging and real-time monitoring during drying helps in detecting and correcting hot spots or cold areas.

The other challenge is the high initial investment cost related with microwave drying equipment. Despite energy savings in the long run, it can be expensive for a medium-sized business to meet this upfront capital. Consequently leasing options or financial incentives from government bodies may help mitigate this problem. Moreover, technological advancements as well as increased adoption rates in the industry has led to a gradual decrease in costs making these systems cheaper.

Finally, another set of challenges arises from regulatory landscape. Adherence to food safety standards and ensuring national and international compliance of microwave drying systems can be intricate. The solutions entail keeping up with changes on regulations; having compliance officers; acquiring systems that are already in line with what food safety authorities demand for. Continuous collaboration with regulatory bodies also facilitates faster implementation of compliant practices.

How do you make your dry more effective?

In order to optimize energy distribution throughout the product thus enhancing drying efficiency in microwave drying systems consider optimizing its power settings so that it operates uniformly across all energy application points within the sample.. Before drying proper pre-treatment processes such as slicing or blanching can be implemented which will significantly reduce time taken during drying hence improving uniformness.As well adjusting air flow plus using correct packaging materials aids greatly in sustaining water contents uniformity hence avoiding excessive desiccation and scorching.Rather than wasting energy through inefficient practices, feedback mechanisms through real-time sensors control monitors on the environment during driers should be employed, leading to the precise removal of moisture contents.

Uniform Drying and Moisture Content Control

Several key techniques are used to enhance uniform drying and moisture content control. Ensuring accurate control of microwave power and timings is therefore important because under-drying or over drying has an impact on product quality. In addition, near-infrared spectroscopy (NIRS) should be used as a tool for the precise determination of moisture content at each stage of the drying process, and a rapid feedback loop enabled by an adaptive control system can dynamically adjust these parameters during production to maintain consistency in all products produced. Encouraging uniform airflow distribution along with incorporating phase transformations into the drying model also contributes to uniform moisture levels.Running calibrations on equipment periodically,checking specifications meticulously as well as using constant surveillance will guarantee good processing conditions and high product quality.

Frequently Asked Questions (FAQs)

Q: What is microwave drying?

A: Microwave drying is a technique that uses microwave energy to remove moisture from different materials. It is a faster method compared to traditional methods like drying rooms and convection ovens, providing efficient and uniform drying.

Q: How does microwave drying work?

A: Microwave drying works by generating microwave energy that penetrates the material, causing water molecules to vibrate and heat up. This heat causes moisture to evaporate, thereby drying the material quickly and uniformly.

Q: What are the advantages of using microwave drying over traditional methods like drying rooms and convection ovens?

A: Microwave drying offers several advantages over traditional methods such as drying rooms and convection ovens. It provides faster drying times, better energy efficiency, uniform drying, and is more effective in preserving the quality and color of the dried material.

Q: What are some common applications of microwave drying?

A: Common applications of microwave drying include food drying, pharmaceutical processing, drying of ceramic materials, wood drying, and many industrial processes where rapid and uniform drying is essential.

Q: How does microwave drying impact the energy efficiency of the drying process?

A: Microwave drying significantly improves the energy efficiency of the drying process. It directly heats the water molecules within the product to be dried, minimizing energy loss and reducing overall drying time, making it more energy-efficient than conventional methods.

Q: Can microwave drying be combined with other drying methods?

A: Yes, microwave drying can be combined with other drying methods such as hot air dryer or vacuum drying to enhance drying kinetics and improve overall efficiency. This combination often results in better quality dried materials and shorter drying times.

Q: What is the effect of microwave drying on the quality of dried materials?

A: The effect of microwave drying on the quality of dried materials is generally positive. It helps to retain color, flavor, and nutritional content better than conventional drying methods. This makes microwave drying an attractive option for food and pharmaceutical industries.

Q: Are there any specific microwave technologies recommended for drying processes?

A: Specific microwave technologies like ferrite microwave technologies and microwave freeze drying are recommended for various drying processes. These technologies are designed to optimize the drying kinetics and enhance the quality of the dried material.

Q: How does microwave drying affect industrial processes?

A: Microwave drying can significantly streamline industrial processes by reducing drying times, improving product quality, and enhancing energy efficiency. This makes it an attractive solution for industries looking to optimize their drying technologies.

Q: What types of products can benefit from microwave drying techniques?

A: A wide range of products can benefit from microwave drying techniques, including food items, pharmaceuticals, ceramics, wood products, and other industrial materials that require efficient and uniform drying.