Leading Supplier of Microwave Thawing Equipment in China

Provider of Online Microwave Thawing Services for Machines

Discover the high-quality services offered by Loyal’s Custom microwave thawing machine Services in China. Optimize your thawing process with our premium services today!

- Customized Solutions

- High Efficiency and Energy Saving

- Reasonable Pricing

- Comprehensive Support

Our microwave thawing machine offers a dependable and high-performing drying solution customized to suit the diverse requirements of different industries.

Home » Microwave Thawing Machine

-

Applications of Microwave Thawing Machine

Microwave thawing machines are innovative devices designed to quickly and efficiently thaw frozen products using microwave energy.

Food Processing Industry

In the food processing sector, microwave thawing machines are invaluable for quickly thawing large quantities of meat, poultry, seafood, and other frozen products. This rapid thawing process helps maintain the quality and safety of the food by reducing the time it spends at temperatures where bacterial growth can occur.

Bakery Industry

Microwave thawing machines provide an efficient solution, allowing bakers to quickly bring frozen dough to the right consistency for baking, thereby reducing preparation times and increasing overall productivity.

Their ability to provide uniform and quick thawing helps maintain product quality, enhances operational efficiency, and supports high standards of safety and hygiene. As a result, they are becoming an essential tool in modern food processing, pharmaceuticals, catering, agriculture, and beyond.

Benefits of Microwave Thawing Technology Quick and Efficient Thawing Method

Microwave thawing technology has revolutionized the way industries handle frozen products, offering a range of benefits that enhance efficiency, quality, and safety.

1. Speed and Efficiency

Microwave thawing is significantly faster than traditional thawing methods. This rapid thawing process helps businesses save time and improve overall productivity.

2. Uniform Thawing

Microwave energy penetrates evenly throughout the frozen product, ensuring uniform thawing.

3. Reduced Bacterial Growth

Microwave thawing minimizes this risk by reducing the time products spend in the temperature danger zone, enhancing food safety and reducing the likelihood of spoilage.

4. Preservation of Quality

Microwave thawing helps in preserving the texture, flavor, and nutritional value of food products.

5. Energy Efficiency

Microwave thawing machines are designed to be energy-efficient. They use less energy compared to traditional methods like water baths or air thawing, helping businesses reduce their energy consumption and lower operational costs.

6. Versatility

Microwave thawing technology is versatile and can be used for a wide range of products, including meat, poultry, seafood, fruits, vegetables, and even pharmaceutical materials.

These advantages make it an ideal choice for industries looking to improve their thawing processes, enhance food safety, and increase overall operational efficiency.

Microwave Thawing Machine: Key Technical Specifications and Parameters

| Microwave Thawing Machine | |

|---|---|

| Defrosting Equipment Work Requirements | Standard Defrosting |

| Specification | 400*600*180mm/Pc |

| Frozen Product | 25kg/Pc Without Packing |

| Capacity | 1000kg/Batch |

| Specification | 1500*700*1690mm |

| Carts | 500kg Loading Capacity |

| Total Power | 10kw(3 Phase, 380V/50Hz) |

| Water/Steam Consumpution | Water:5kg/H,Steam: 13kg/H |

| Thawing Time | 3-8min |

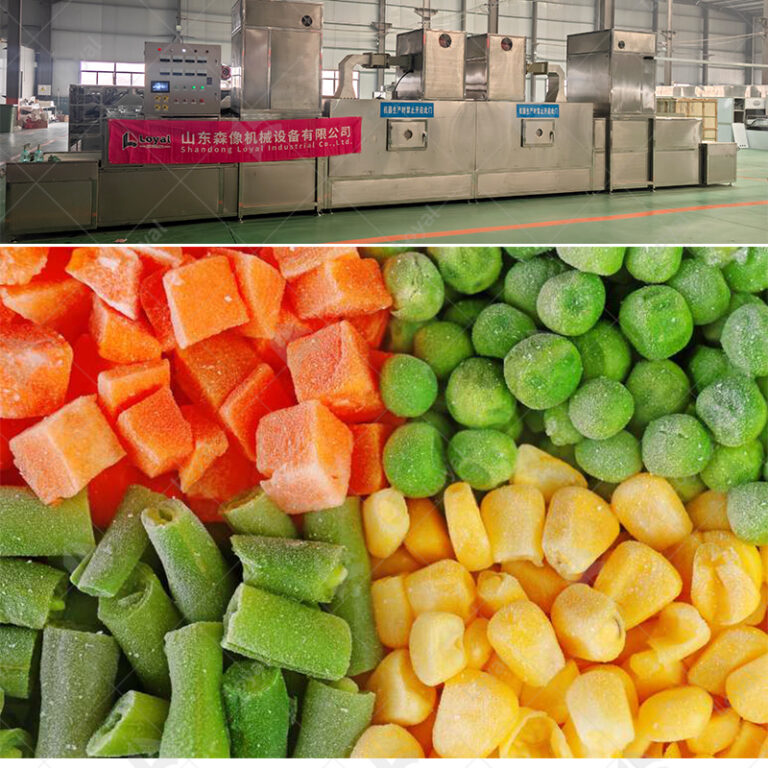

Microwave Thawing Machines From Reliable Suppliers For Quick Defrosting

Display Of Material Thawing Results From Microwave Thawing Machine

Factory Tour of Microwave Thawing Machines - Explore Our Facilities

-

Why choose Loyal's Microwave Thawing Machines?

When it comes to selecting the best microwave thawing machines for your business, Loyal stands out as a leader in the industry.

1. Advanced Technology

Loyal’s microwave thawing machines are built using the latest in microwave technology, ensuring efficient and uniform thawing.

2. High Efficiency

By utilizing precise microwave energy, Loyal’s thawing machines ensure that your frozen products are thawed quickly and evenly, saving both time and energy.

3. Quality and Reliability

Our microwave thawing machines are constructed with high-grade materials and undergo rigorous testing to ensure they meet the highest standards of performance and durability.

4. Energy Savings

They use less energy compared to traditional thawing methods, making them an economical and environmentally friendly option.

5. Versatile Applications

Loyal’s machines are versatile and suitable for a wide range of applications, from food processing to pharmaceuticals.

Discover Top-Quality Microwave Thawing Machines for Sale - Explore Now!

Are you tired of slow, uneven thawing processes that compromise the quality of your products? Discover our range of high-performance microwave thawing machines designed to revolutionize the way you handle frozen goods. Explore our selection today and find the perfect machine to enhance your operations.

Browse Our Selection

Take a look at our extensive range of microwave thawing machines. Each product page includes detailed specifications, features, and customer feedback to help you make the best choice for your needs. Our knowledgeable team is ready to assist you with any inquiries and offer tailored advice.

Get in Touch

Ready to upgrade your thawing process? Contact us today to learn more about our microwave thawing machines, request a quote, or arrange a demonstration. Our dedicated support team is here to ensure you find the perfect solution for your business.

Don’t wait to experience the benefits of top-quality microwave thawing machines. Explore our selection now and take your operations to the next level!

Latest Articles ※

Autoclave Guide: Choosing the Best Can Food Sterilization Machine

In food preservation, autoclaves are essential to ensure that canned food products are safe and have long shelf life. This guide is intended to help readers understand the various aspects...

Revolutionizing Pet Food Processing: The Ultimate Guide to Pet Food Sterilization Machines

Today, in the ever-changing pet food industry, ensuring safety and product quality is of utmost importance. With an increasing concern for pets’ health by their owners, there has been a...

Complete Guide to Using a Food Sterilization Machine for Packaged Food Preservation

In the endlessly changing world of food preservation, machines for sterilizing food have become lifelines for preserving the freshness and safety of packaged foods. This guide is inclusive in presenting...

Maximizing Efficiency with Industrial Food Sterilization Machines: A Comprehensive Guide to Autoclave

Safety and quality are of utmost importance in the ever-changing world of food processing. This guide covers the importance of industrial food sterilization machines, especially autoclaves, in keeping food authentic....

Related topics about Microwave Thawing Machines

Microwave Thawing Machine : Common Questions Answered

Explore the advantages of the Microwave Thawing Machine for effective thawing.

Q: What is a microwave thawing machine?

A: A microwave thawing machine is a device that uses microwave energy to quickly defrost frozen food products such as meat, poultry, fish, and vegetables. It is commonly found in industrial food processing facilities.

Q: How does the thawing process work in these machines?

A: The thawing process in a microwave thawing machine involves the use of a microwave generator that produces microwave energy. This energy penetrates the frozen materials, causing the water molecules to vibrate and generate heat, which gradually defrosts the frozen products from both the inside and outside.

Q: Can microwave thawing machines be used for all types of frozen food?

A: Yes, microwave thawing machines can be used to defrost a wide variety of frozen food including meat, poultry, seafood such as shrimp, vegetables, and processed food products like sausage and steak. However, each type of frozen material may require specific settings for optimal thawing.

Q: How does the thawing speed of microwave thawing machines compare to traditional methods?

A: Microwave thawing machines significantly accelerate the thawing speed compared to traditional methods. What might take hours using conventional methods like water baths or air thawing can often be accomplished in minutes with a microwave defrost machine, thereby increasing efficiency in food processing operations.

Q: How do microwave thawing machines compare with industrial microwave dryers?

A: While microwave thawing machines and industrial microwave dryers both use microwave energy, the former is specifically designed for the defrosting process, whereas the latter is used for drying food products. Industrial microwave dryers remove moisture from food, often as a preservation step, whereas thawing machines aim to safely and efficiently defrost frozen food materials.

Q: What are the benefits of using an industrial microwave oven for thawing?

A: Benefits include quicker defrosting times, improved food safety due to reduced time within the temperature danger zone, and more consistent thawing results. It also minimizes the risk of product contamination and preserves the quality and texture of the food products.

Q: What features should a good industrial defrosting equipment have?

A: A good industrial defrosting equipment should have features like an efficient microwave generator, adjustable temperature controls, durable stainless steel construction, automatic microwave controls, and a large microwave cavity for uniform thawing. It should also ensure quick defrosting while maintaining the quality of the food products.

Q: Are there any special considerations for thawing deep frozen products like large cuts of meat?

A: Yes, when thawing deep frozen products such as large cuts of meat or whole poultry, it is important to use appropriate settings to ensure even thawing throughout the product. Utilizing the correct microwave energy and temperature settings helps prevent the outside from cooking while the inside remains frozen.