Modern food safety protocols are critically depending on the rising of ultraviolet (UV) food sterilizer machines that uses advanced technological approaches to accomplish their objective of making consumables free from living organisms. These gadgets use a particular range of ultraviolet (U.V.) light which is recognized for germicidal effects called UV-C to deactivate microorganisms like bacteria, viruses and other pathogens found on the surface of foodstuff. With increased concerns on microbial contamination and foodborne diseases, it has now become more essential than ever before to embrace such modern sterilization technologies. This paper will analyze how UV food sterilizer machines work in order to describe their mechanisms, effectiveness and superiority over traditional methods of sterilization. Discussion and analysis of technical features as well as practical functions have offered readers a comprehensive view about recent processes implied in the process of keeping foods away from any possible danger by using up-to-date methods of protection from pathogenic agents.

What is a UV Food Sterilizer Machine?

A unit called a UV food sterilizer machine is designed to disinfect foodstuff by emitting ultraviolet (UV) light, particularly within the UV-C spectrum known for its germicidal properties. Such machines use the energy of UV-C light to penetrate into cells of bacteria, viruses, and fungi that disrupts their DNA or RNA and makes them inactive. The use of UV light for sterilization does not involve any heat hence it keeps original quality, texture as well as nutrition value of the food items. This way is more efficient, fast and eco-friendly than traditional chemical based techniques used in disinfection thus becoming an important part of modern food safety.

Understanding the Basics of a Food Sterilizer

The ability of a UV food sterilizer machine to work relies on some basic principles which are necessary for its effectiveness. These devices employ ultraviolet C (UV-C) light which usually falls within the 200-280 nm range that is ideal for germicidal action. Light photons are absorbed by nucleic acids in microorganisms leading to production of thymine dimers in DNA or uracil dimers in RNA. As a result, pathogens cannot replicate themselves because they cannot undergo pyrimidine dimerization.

Another operational aspect critical to this machine entails technical parameters such as the intensity expressed in microjoules per square centimeter (µJ/cm²), exposure time needed to administer lethal dose and others. For example, fluence between 40-100 mJ/cm2 has been noted to be effective against various types of microbes for thorough sterilizing purposes. On top of that, distance from emitters side up to product surface plays a significant role since intensity diminishes exponentially with rising space.

Furthermore, microbial reduction efficacy or log reduction is also essential; it shows how effective treatments directed against targeted microorganisms were made using “logs” notation system reducing four logs simply means killing about 99% percent of the target pathogens. Furthermore, since ultraviolet C has a low penetration depth and its effects are restricted to the surface layers of food; it is necessary to evenly expose all surfaces.

For instance, contemporary UV sterilizers may have provisions for use optimization like rotating trays that cause uniform UV-C exposure or sensors for dose delivery control. Safety interlocks, on the other hand, are incorporated in such machines so as to avert any accidental exposure of operators to UV radiation making their utilization safe. These gadgets pass through tests according to international standards including ISO 15858:2016 hence they can be trusted with responsibility for food sterilization effectiveness and safety.

How UV Light Works in a UV Sterilizer Machine

The normal operation of a UV sterilizer machine involves exposing DNA and RNA structure of microorganisms to ultraviolet light specifically in the form of UV-C radiation. The replication process of these pathogens is thus interrupted through pyrimidine dimers formed between thymine bases in DNA and uracil bases in RNA which give rise to structural abnormalities in DNA leading to its destruction.

- UV-C Light Intensity: This dictates how much energy is produced by it in units known as microjoules per square centimeter (µJ/cm²).

- Exposure Time: A period during which harmful agents are subjected under influence of ultraviolet C rays while still being on contact with them until optimum disinfection is achieved.

- Fluence: To achieve effective sterilization, fluence should range from 40-100 mJ/cm² but will vary depending on the type of organism.

- Distance: As distance from emitters increases at exponential rates so does efficacy towards targeted surface diminish hence there should be an optimal length ensuring sufficient illumination strength reaches food material across which this machine operates.

- Log reduction is a scale that measures the ability to reduce microbial load; for instance, 4-log reduction means a decrease of 99.99% in organisms targeted.

The modern UV sterilizers can be designed with different specifications as follows:

- Rotating Trays: These move food surfaces under UV-C light continuously so as to ensure uniform exposure.

- Dose Delivery Sensors: It monitors and controls the amount of UV-C delivered.

- Safety Interlocks: They are meant to prevent accidental human exposure to harmful UV-C radiation.

These parameters and features are assessed against global standards like ISO 15858:2016 for quality assurance on performance in disinfection processes.

The Role of Ultraviolet Rays in Food Sterilization

UV-C light has a significant role in food sterilization due to its germicidal properties. Reaching the utmost effectiveness in sterilization is through careful calibration of several technical parameters:

- UV-C Light Intensity (µJ/cm²): This instrument is essential because it defines how strong UV-C light can deactivate microbes. Typically, higher intensity means greater microbial killing.

- Exposure Time: Pathogens need to be exposed to UV-C light sufficiently to ensure full disinfection. The required exposure time depends on factors like the light intensity and the type of microorganisms present.

- Fluence (mJ/cm²): Sterilization efficacy significantly depends on the total energy delivered to the food surface area. Generally, fluence should fall between 40-100 mJ/cm², with a careful adjustment depending on target organisms.

- Distance: The effectiveness of UV-C light wanes as the distance from the source increases. Consequently, positioning UV-C emitters appropriately will help maximize light penetration efficiency onto the food surface.

- Log Reduction: The extent by which microbial load decreases is measured by this index whereby increased log reduction indicates better results. For instance, a 4-log reduction corresponds to removal of 99.99% microbes.

- Rotating Trays: These are used for uniformity purposes in terms of exposure, ensuring there are no dark spots while ensuring all surfaces are reached properly.

- Dose Delivery Sensors: These sensors enable real-time monitoring and control of UV-C light doses, thereby ensuring that the exact right amount of ultraviolet radiation reaches each instant.

- Safety Interlocks: Incorporating these systems into an operation prevents unplanned human contact with UV-C rays, consequently ensuring the safety of boating operators.

The combination of such technical parameters with standards like ISO 15858:2016 shows how deep and secure is UV sterilizing within the food industry.

How Effective is UV Light for Food Sterilization?

It has been demonstrated that UV light, notably UV-C light, is highly effective for sterilizing food. It impairs the DNA of microorganisms making them not to be able to replicate thereby drastically reducing their populations. Efficacy depends on factors such as fluence, exposure time and physical properties of the treated food material. The efficiency of this form of light can cause log reductions from 2 to 5 which roughly translate into a decrease ranging from 99% to 99.999% in microbial load. Nonetheless, shadowing by surfaces and food geometry can minimize its effect, so rotating trays and dose delivery sensors are employed to guarantee even exposure throughout and better results. In this context, the author thinks that UV-C technology plays a great role towards improving food safety once appropriately utilized and monitored.

UV Light Kills Bacteria and Viruses on Food.

Yes! On account, UV light kills bacteria as well as viruses on food efficiently. This renders pathogens inactive through the disruption of their DNA or RNA by penetrating their cells with wavelengths between 200-280 nm (UV-C). Researches have certified the effectiveness of these methods for reducing E.coli in poultry products, Salmonella in seafoods and Listeria monocytogenes found in ready-to-eat foods among others.

Some key technical parameters for efficient UV-C sterilization include:

- Wavelength Range: Disruption of microbial DNA/RNA by UV-C radiation primarily occurs at a wavelength around 254nm.

- Fluence (Dose): To achieve considerable reduction of microbes usually requires using doses within the range of about 50-100 mJ/cm².

- Exposure Time: Proper exposure time often spans several seconds up to minutes ensuring effective disinfection.

- Intensity: More powerful lamps will result into shorter treatment durations.

Results also show that optimizing these parameters makes UV-C light an excellent tool for maintaining safe food by diminishing the microbial load on various food products.

Advantages of Using UV Sterilizers in Food and Beverage Manufacturing

Many benefits are associated with employing UV sterilization in food and beverage processing to ensure that these products are free from harmful pathogens. This is a non-thermal process, meaning that it does not subject food or beverages to high temperatures, thereby maintaining nutritional quality and sensory appeal. This approach has potent germicidal attributes against a wide range of microorganisms, such as bacteria, viruses, and fungi.

Furthermore, UV sterilizers take very little contact time to significantly reduce microbes, usually within seconds. This improves the speed of operation and throughput in industrial applications. Furthermore, UV systems are energy efficient and, hence, environmentally friendly since they use less water and chemicals compared to conventional sanitization methods.

UV sterilization’s effectiveness in food and beverage industries can best be described through various technical parameters:

- Wavelength: Industrial ultraviolet sterilizers mostly employ a 254 nm wavelength to degrade microbial DNA without diminishing the quality of foods.

- Dosage (fluence): Typical values for this parameter should range from 100 to 400 J/m², depending on the type of microorganisms being targeted and the specific application.

- Exposure time: Usual exposure times vary between fractions of a second to some minutes making sure all bacteria have been killed.

With regard to ISO 15858:2016, this method conforms with established international standards used by companies operating in these sectors thus proving its efficiency and safety aspects. Proper use of such equipment could, therefore, help produce safer products with higher value while at the same time promoting sustainable manufacturing practices.

Comparing UV Sterilization to Other Sterilization Methods

As such, comparing UV sterilization with other sterilization methods, such as thermal processing, chemical sanitizing, and ultrasonic methods, yields some technical parameters and performance metrics that can be used as good benchmarks.

Thermal processing consists of applying heat to destroy microorganisms. However it is time-consuming and requires a large amount of energy. For instance, pasteurization normally calls for temperatures around 72°C for approximately 15 seconds. The nutritional and sensory properties of food may be destroyed by high-temperature processes that UV sterilization prevents since it does not involve heating.

Chemical sanitizing uses chlorine, peracetic acid or ozone among others to inactivate microbes. Despite being effective in ensuring food safety, the use of these chemicals results in chemical residues on food surfaces, which could have harmful effects on human health, leading to potential changes in product organoleptic attributes. Furthermore, this method has higher costs associated with operations due to chemicals required for purchase purposes as well as storage and handling safety issues. In comparison, no contaminants are introduced during the process thus maintaining the wholesomeness and safety of food through UV sterilization.

Ultrasonic technology works by using sound waves with high frequencies to break down the structures of microbial cells. Ultrasonic sterilization is promising but frequently less effective when used alone hence requires either thermal or chemical treatments alongside for proper microbial control. Moreover, the application of ultrasonics can be complex, sometimes making it impractical for widespread industrial use owing to its energy requirements.

In conclusion, UV sterilization stands out because it is fast acting without chemicals besides not affecting the quality of food greatly; hence, it is mostly preferred in many industries today due to its low operational costs and sustainable approaches towards production in the F&B sector. Below are given certain major technical parameters for each method:

- Thermal Processing:

- Temperature: Typically 72°C for pasteurization

- Exposure Time: Approximately 15 seconds or more

- Chemical Sanitization:

- Chemicals: Chlorine, peracetic acid, ozone

- Residue Management: Required to ensure food safety

- Ultrasonic Methods:

- Frequency: High-frequency sound waves

- Integration: Often combined with other treatments

It is clear that in many industrial applications, UV sterilization operating at a wavelength of 254 nm, mainly in UV-C, is superior due to its dosage range of 100-400 J/m² and very short exposure periods.

How to Integrate UV Sterilizer Machines into Food Processing Lines?

The integration of UV sterilizers in food processing lines involves several critical steps to ensure its effectiveness and safety. Initially, one must carry out an extensive survey of the layout of the process line so that they can determine optimum sites to place the UV units particularly at points where microbial risks are highest such as after washing and before packaging stages. Therefore, when selecting a UV sterilizer it is important to look for specifications like wavelength (UV-C preferred 254 nm) and dosage needed to achieve certain levels of microbe kill.

The next step is ensuring compatibility between existing machinery and conveyor systems with UV units. This may involve coming up with custom mounts that synchronize with line speeds for correct exposure time maintenance. Additionally, having monitoring systems for real-time measurements of UV intensity meters as well as dosimeter readouts will help maintain its continuous efficacy and compliance with safety standards.

Regular maintenance procedures and cleaning protocols should be developed to avoid deposit build-up on UV lamps and reflectors, which could diminish their efficiency. Finally, training staff on operational principles and safe use techniques relevant to ultraviolet technology promotes seamless integration into activities and, hence, good performance.

Designing a Production Line’s UV Sterilizer

When designing uv sterilizers for production lines, there are many considerations that must be made in order to effect both efficiency and safety. First and foremost, germicidal properties necessitate selection of the appropriate wavelength of uv radiation which is typically at 254 nm (such as in case of germicidal lamps). The specific pathogens that are targeted by the processing speed employed along a given production line determine the required dosage together with exposure period needed for achieving microbial inactivation.

Customizing the dimensions and mechanics associated with an existing manufacturing plant usually requires modification in the design of such a unit itself. Manufacturing an appropriate mounting arrangement and ensuring proper alignment will render compatibility possible when dealing with conveyors and other systems used within this facility. Moreover, the supply of reflective materials to be placed within should also provide for maximum surface exposure to the UV light irradiation process.

For this reason, inclusion of real-time monitoring systems capable of tracking both UV intensity and lamp performance is vital. These will immediately give feedback as well as alarms if the UV output falls below critical levels, thus ensuring that disinfection efficacy continues to remain effective. Furthermore, one must have a maintenance plan for cleaning and replacement of UV lamps that may have been clogged by dirt or any other kind of residue.

Also, compliance with regulatory guidelines and safety standards is crucial. Adequate set up in terms of shielding is necessary so that workers are not harmed by accidental exposure towards harmful UV light rays. Therefore, comprehensive staff training on operational procedures and safety protocols should be done so as to create a safe and efficient production environment.

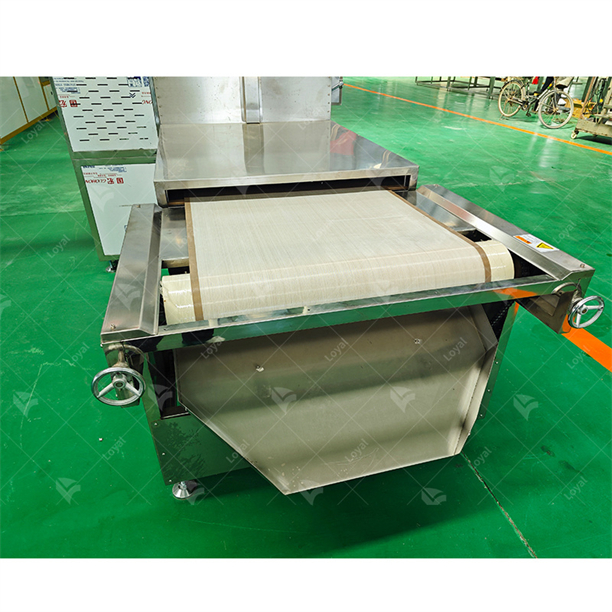

Placement of UV Food Sterilizers within the Conveyor Belt System

When installing some UV food sterilizers at conveyor belt system sites, it’s very important that one positions their sterilizer units in such a manner that they maximize exposure to ultraviolet rays. By locating them above and under the conveyors, it becomes easy to subject all surfaces of food items to sufficient amounts of irradiation from these sources. The positioning should involve account for conveyor belt speed so that exposure time meets dose requirements for microbial destruction. Reflective surfaces inside can improve the distribution of the ultraviolet light across multiple parts while enabling proper access for maintenance without interfering with operation flow since there must continue to be a way into sterilizers once these are needed urgently during production sessions or otherwise easily accessible on-demand situations arise.

What to Look for in a UV Food Sterilizer Machine?

When choosing a machine for sterilizing ultraviolet foods, consider the wavelength and intensity of the UV radiations it emits as these are critical factors in microbial inactivation. A well-constructed machine made of heavy duty materials that can endure food processing environmental conditions is necessary. Consider looking for advanced monitoring systems that check on the output of UV and alert operators whenever there is need to change lamp or do maintenance. Besides, it is good if it complies with relevant food industry standards and safety regulations to ensure its effectiveness and safeness when in operation. Furthermore, ease of integration into existing production lines and low operational costs should be taken into account. Finally, ensure that it comes with comprehensive customer support and service options that can address any troubleshooting or maintenance needs promptly.

Key Features of a Ultraviolet Sterilization Machine

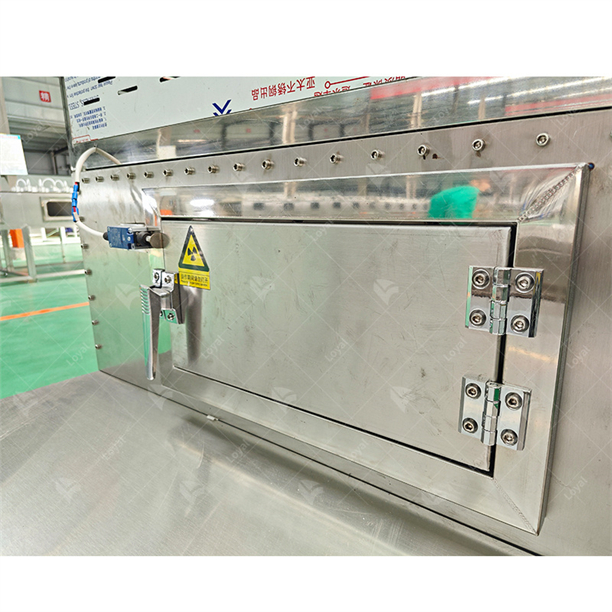

Key features of an ultraviolet sterilization machine include high-efficiency UV-C lamps that emit light at the optimal germicidal wavelength of 254 nm, ensuring maximum microbial inactivation. Therefore, the machine ought to have a strong structure that resists corrosion, usually manufactured out of stainless steel or other durable materials, because they will be consistently exposed to food processing environments. It also has an advanced control system providing real-time monitoring and adjustment of UV intensity and exposure duration, optimizing sterilization efficiency while meeting safety standards at the same time . Reflective surfaces or specialized chamber designs may improve UV light distribution, resulting in better performance generally on average . Additionally, easy access for lamp replacement and routine maintenance is vital to keep downtime minimal enabling continuous operation. Finally, integrating safety interlocks to prevent accidental UV exposure as well as compatibility with existing production lines are crucial for smooth running operations within regulatory frameworks.

Understanding the Structure of the UV Sterilizer

The structure of a UV sterilizer typically consists of several key components. The main element here would normally be high-efficiency uv-c lamps whose design is meant to emit light at the optimal germs killing wavelength of 254 nm. These lamps are contained in a chamber that can resist corrosion and is usually made of stainless steel to be able to stand the harsh conditions of the food processing environment. The design for the chamber frequently includes surfaces that reflect light so as to spread it evenly over its entire extent for complete microorganisms killing. Additionally, an advanced control system is used to supervise and adjust the intensity of UV rays and time of exposure, hence allowing for accurate sterilization processes. It cannot be overstated how much safety interlocks are needed to protect against accidental ultraviolet radiation contact on site personnel that thrive on operations. Finally, its structure has been made easy for maintenance with accessible lamp compartments ensuring quick replacement which leads to shorter downtimes thereby maintaining continuous operational efficiency.

Choosing the Right Sterilization Equipment for Your Needs

Several critical factors must be considered when selecting the appropriate sterilization equipment. Firstly, assess the type of microorganisms present and specific sterilization needs upon which you will then determine the optimum wavelength and intensity of UV required. Secondly, evaluate throughput as well as capacity offered by sterilizer so that it meets your operation’s volume requirements. Moreover, compatibility with existing equipment and ease of integration into current workflows need to be assessed along with any required maintenance routine or availability of replacement parts . Thereafter, consider the overall cost, including initial investment costs incurred at purchase time , operating expenses, as well as potential savings from improved efficiency and reduced downtime . Last but not least; compliance industry standards should be maintained without compromising on regulatory requirements related safety or efficacy during process like this one leading up to them all

How to Use a UV Food Sterilizer Machine?

What is the procedure for using a Drying UV Food Sterilizer? Start by ensuring that the device sits on a firm and flat surface in a clean environment. Before use, ensure that all parts are correctly fitted and that the lamps emit ultra violet rays. Next, put the foodstuff inside the sterilization cabinet ensuring uniformity and un-overlapping to promote maximum exposure to ultraviolet rays. The recommended time and intensity of sterilization should be set depending on type of food and manufacturer’s specifications. Turn it on to start sterilizing until it finishes its cycle. Once done, take away the food materials without being exposed directly into UV rays. Clean up chamber regularly; also replace ultraviolet lights as required by manufacturers for continuous efficiency and safety maintainance.

A Step-by-Step Guide to Using Ultra Violet Light Sterilizers

- Preparation:

- Inspecting Device: Check if each UV lamp is fixed properly in place while maintaining its genuine conditions with no other element at all in chamber.

- Positioning: Before switching it on, locate a suitable place where this appliance cannot move or fall while still being well cleaned.

- Loading up the Sterilizer:

- Uniform Distribution: Put these things into this particular enclosure without letting them touch one another in order to allow enough penetration of these radiations.

- Treat items with caution so as not to contaminate them.

- Setting Parameters:

- Time Slot And Intensity: Adjust these two depending on what you have been advised in respect to how long or strong they must be from manual books like these common ones;

- Starting the Procedure: Turn your device off after it has started sterilizing by carefully closing this compartment so that nothing escapes through an opening designed only for light escape.

- Just follow along using that little display or signal lights as shown here so far if your machine needs any sort of monitoring during its running period because otherwise don’t even dare anything connected with it until then!

- Post Sterilization:

- Removing Items: Open the chamber and take out things that were sterilized without being exposed to UV light.

- Safety Measures: Protective attire must be worn where applicable, as well as avoidance of direct looking at the lamp in course of taking them off.

- Maintenance:

- Regular Cleaning: Use proper detergents to clean the sterilization chamber regularly so that no residues grow there.

- Replacement of Bulbs: Stick by what the manufacturer tells you about replacing these bulbs. Usually UV lamps need to be replaced after 8000-12000 hours because that is when they become ineffective.

- System Verification: The machine has several systems that should be checked periodically for optimal performance; these may include pointers like wear signs, fit malfunctions, or unusual performance.

Technical Parameters to Consider:

- UV Wavelengths: Often, effective sterilization utilizes ultraviolet light within this range of 200-280nm wavelength.

- Lamp Life: It is estimated that each one can last up to around 8,000 hours depending on their types or quality produced before expiration date comes due which is after approximately 8000-12000 hours worth of service life

- Exposure Time: The period of exposure depends on the types and amount of materials being sterilized and can vary between 5 and 60 minutes according to settings provided above for your convenience;

- Intensity: As per most studies conducted earlier 400 – 800 µW/cm² usually represents appropriate intensities during successful process.

Maintenance Hints for a Food Ultraviolet Sterilizer Machine

In order to enhance the efficiency of operation of food ultraviolet sterilizer machine, incorporate the following detailed maintenance tips in your routine.Firstly, ensure that you have regular checks and cleaning to eliminate any residues that may accumulate which would impair UV penetration due to accumulated particles hence reducing sterility. Use approved detergents from the manufacturer so as not to spoil it.Secondly, follow the schedule of replacement UV lamp which is usually between 8,000 to 12,000 hours of usage in order to maintain effective levels of irradiation. Monitoring lamp performance can help identify when replacements are necessary. Moreover, one should regularly check the machine’s components and systems for wear or damage like loose fittings or irregular performance so as to fix them before they become a big problem.

Calibration of device’s intensity properly along with exposure time settings is also essential in ensuring objects receive the right dosage required for effective sterilization.

Common Mistakes To Avoid When Using Food Sterilizer Machines

However, one common mistake is overloading the sterilizer with items such that it blocks out every possible ray of UV light resulting into ineffective sterilization.Always provide adequate spacing between articles to allow proper UV exposure. Additionally ignoring regular upkeep such as not cleaning the UV bulbs or replacing them when they are no longer efficient enough both undermine functionality.In addition, false calibration of exposure time and intensity settings can cause under or over-sterilization; hence, adherence to manufacturer guidelines guarantees optimal performance.

Are UV Food Sterilizer Machines Safe?

General perception is that UV food sterilizer machines are safe when used properly and according to the manufacturers’ instructions. Ultraviolet light, especially UV-C, is utilized in these devices because of its powerful germicidal properties that can destroy bacteria, viruses and other pathogens on the surface of food. The most important safety aspect is ensuring that the equipment prevents direct exposure of ultra violet (UV) light to skin or eyes because UV-C causes damage to human tissues. Modern day UV sterilizers often have in-built safety features like automatic shut-off mechanisms when the chamber is opened. Proper use also requires following recommended exposure times and keeping it adequately maintained so as to avoid machine failures. When followed, these protocols make UV food sterilizers provide a reliable method for improving food safety by significantly reducing microbial contamination.

Precautions for Using Commercial UV Sterilizers

Commercial UV sterilizers must be handled carefully with strict observance of all safety requirements aimed at ensuring their effectiveness and user protection. Firstly, always wear suitable personal protective equipment (PPE), such as gloves and UV-resistant eyewear whenever you are working with ultraviolet C light sources to safeguard against accidental exposure to them. If not well-ventilated, ozone may accumulate as a by-product of using ultraviolet C lamps, which can cause harm when it gets into our lungs through inhalation. Regularly check for any signs of damage on the machine and ascertain whether all safety interlocks are functioning well enough. This includes making sure that whenever the chamber lid opens, the machine shuts down automatically, too. Moreover, adhere strictly to manufacturer’s recommended exposure time and ensure even spacing between items in the chamber so that they get uniform amount of UV/ surface area where it comes in contact with each item remains constant over time. Regular maintenance, including cleaning and timely replacement of Ultra Violet bulbs, are necessary for the efficient functioning of the sterilizer.

Hazards Posed By Ultraviolet Germicidal Lamps

If handled improperly, exposure to ultraviolet germicidal lamps can pose several health risks. First, there is the possibility of skin burns and eye injuries such as photokeratitis or cataracts because of direct or indirect UV-C radiation exposure. Due to UV-C light’s more energetic nature and being more destructive than other forms of UV radiation, even very brief exposures may have severe consequences. Long term exposure increases the risk of more serious skin conditions including increased chances of skin cancer occurring. Secondly, UV-C lamps are capable of generating ozone gas, which, when inhaled, can result in respiratory problems such as coughing, sore throat, and shortness of breath. In order to be effective at mitigating these risks, it is important to use proper safety equipment and adequate shielding.

UV Sterilization Machines’ Utilization Regulations

The rules that govern the use of UV sterilization machines differ from one region to another but generally include safety norms and operational guidelines to safeguard both users and the surrounding environment. In America, the United States Food and Drug Administration (FDA) is responsible for regulating UV sterilization equipment as well as making them comply with a set standard under the federal Food, drug, and Cosmetic Act. Tests must be conducted on these devices to check their effectiveness and safety, and manufacturers have to give enough labeling in addition to instructions on how they can be utilized safely. Similarly, OSHA offers guidance that concerns workplace exposure to ultraviolet radiation with respect to PPE (personal protective equipment) such as goggles, aprons, face shields among others, as well as engineering controls meant for minimizing body contact hazards. EPA might also have regulations concerning environmental impact associated with UV sterility machines including ozone emissions. Compliance with these standards ensures safe and appropriate usage of UV sterilization machinery which mitigates potential health threats among users or members of public in general.

Frequently Asked Questions (FAQs)

Q: What is the principle of ultraviolet food sterilization?

A: The principle of ultraviolet sterilization involves using ultraviolet rays, specifically C-band ultraviolet (UV-C), which can kill microorganisms such as bacteria, viruses, and spores by disrupting their deoxyribonucleic acid (DNA) and other cellular components. This physical disinfection method is effective in ensuring that food remains safe for consumption without the risk of secondary pollution.

Q: How is a UV food sterilizer machine used in the food processing industry?

A: A UV food sterilizer machine is widely used in the food processing industry, including food factories and beverage processing and packaging plants. It helps sterilize food production equipment, surfaces, and even the food itself to ensure a hygienic production environment and safe products for consumers.

Q: Why are C-band ultraviolet rays used in UV food sterilizer machines?

A: C-band ultraviolet rays are used in UV food sterilizer machines because they are highly effective at disrupting the DNA of microorganisms. This sterilization principle makes it possible to inactivate bacteria, viruses, and other pathogens without using harmful chemicals, thereby preventing secondary pollution and maintaining food safety.

Q: What are the benefits of using an ultraviolet food sterilizer compared to traditional sterilization methods?

A: The benefits of using an ultraviolet food sterilizer include a chemical-free sterilization process, reduced risk of secondary pollution, and the ability to quickly and effectively kill microorganisms. It is also an energy-efficient method that does not require high temperatures, making it suitable for sensitive foods and widely used in the processing industry.

Q: How do UV food sterilizer machines prevent secondary pollution?

A: UV food sterilizer machines prevent secondary pollution by using ultraviolet light to directly kill microorganisms without the need for chemical disinfectants. This process minimizes the risk of introducing harmful substances into the food production environment and ensures that the sterilization area remains clean and safe.

Q: How does a UV tunnel work in the context of food sterilization?

A: A UV tunnel works by passing food items or packaging through a conveyor system equipped with UV-C lamp tubes. These tubes emit ultraviolet light that sterilizes the surface of the items as they move through the tunnel, ensuring thorough and consistent disinfection without manual handling or chemicals.

Q: What factors should be considered when selecting a UV food sterilizer machine?

A: When selecting a UV food sterilizer machine, factors to consider include the size and layout of the sterilization area, the power supply requirements, the type of microorganisms to be targeted (e.g., bacteria, spores), the warranty period offered by the manufacturer, and customer reviews of the machine’s performance and reliability.

Q: Can ultraviolet food sterilizers be used in hospital settings?

A: Yes, ultraviolet food sterilizers are widely used in hospitals, primarily for sterilizing medical equipment, surfaces, and even water used in medical settings. The principle of ultraviolet sterilization is effective in such environments due to its ability to kill a wide range of pathogens without leaving residues.

Q: How does UV sterilization impact food quality?

A: UV sterilization does not involve high temperatures or chemicals, which means it does not alter the taste, texture, or nutritional value of food. This makes it a preferred method for sterilizing sensitive food products and ensuring they remain safe and high-quality for consumers.

Q: Are there any limitations to using UV food sterilizer machines?

A: Some limitations of using UV food sterilizer machines include the need for direct exposure to ultraviolet light for optimal effectiveness, the potential for reduced efficacy on opaque or uneven surfaces, and the requirement for regular maintenance of the UV lamp tubes. Despite these limitations, UV sterilizers remain a popular choice in the food processing equipment sector for their efficiency and safety benefits.