Drying technology has drastically changed over the past few years across pharmaceuticals and food processing industries. In the preservation of commodities, traditional freeze-drying methods were considered the best method in terms of maintaining their quality and freshness. Still, this perception is being countered by new microwave vacuum-drying technology. This article will examine why it has been adopted more widely, including its efficiency in terms of time taken or power consumed, cost-effectiveness, and ability to retain quality, among others. It also seeks to inform readers about these new technological improvements that have led to this shift in thinking and why many businesses now prefer using microwaves with reduced pressure over freezing them under vacuum conditions, as was done before.

What is microwave vacuum drying, and how does it work?

Image source: https://www.pueschner.com/

Microwave vacuum drying effectively removes water from things using microwave radiation and the vacuum. Conventional drying depends on heat transfer through conduction, convection, or radiation, which is a slow process, unlike the microwave vacuum drying technique, where electromagnetic waves are used to rapidly heat the moisture within the material, leading to its evaporation at a much lower temperature due to reduced boiling point under vacuum condition. As a result, this method consumes less time for drying with preserved quality and nutritional value of dried products. It is suitable for materials sensitive to temperature since it prevents thermal degradation that might cause changes in their properties.

Critical principles behind microwave vacuum drying

The fundamental principles of microwave vacuum drying are rooted in microwaves and vacuum technology working together to eliminate moisture from products quickly while still preserving their quality. To begin with, materials absorb microwave radiation, causing water molecules within them to shake and create internal heat. This kind of heating makes moisture evaporate fast from the product in two ways: One, it boils off externally as heated by surrounding hot air, or second, via evaporation following boiling within the material itself and then diffusing outwards into the atmosphere. Secondly, the application of vacuum condition lowers boiling point such that even at very low temperatures, water can still cook, hence escaping rapidly out of the item being dried, thereby removing most if not all remaining amounts of wetness from that place at a much faster rate than would have been possible under normal atmospheric pressure.

Furthermore, this unique approach also serves as a quicker method for drying because oxygen is limited in a vacuum, where oxidation reactions are suppressed due to the absence or reduction thereof, which could have been caused by exposure to high temperatures during conventional drying methods; hence, preventing them from taking place, leading to the production of better-quality dried materials.

The drying process of a microwave dryer

The drying process of a microwave dryer utilizes microwave energy and vacuuming to remove moisture from products. First, an item is put in the dryer and then exposed to microwave radiation that infiltrates it, making water molecules vibrate, thus generating heat. This heat rapidly dries out the wetness. At the same time, a vacuum is created, which lowers the boiling point of water, making it possible for evaporation to take place at much lesser degrees centigrade. This step ensures quick drying and preservation of goods’ quality with nutritional value, keeping them unaltered. Continuous moisture removal under vacuum also prevents reabsorption, leading to uniformly dry output. Such an improved method has one great advantage over traditional methods: it shortens the time taken for drying while saving power used and keeping original properties intact.

Advantages of using a microwave vacuum dryer

To begin with, microwave vacuum drying has several benefits in comparison with traditional ways of drying. The primary advantage is that it takes a much shorter time for objects to dry under this method, thus making the process faster and more efficient. Secondly, the lower temperatures in this kind of drying help retain the nutritional value, taste, and color of dehydrated products. Thirdly, power consumption is much less than required for ordinary hot air drying, saving costs and conserving the environment by reducing energy use. Apart from these points, another important feature is its gentle process, which prevents thermal degradation so that delicate parts or structures will not be destroyed by heat. All in all, microwave vacuum drying offers a better solution to dry things at a low price quickly.

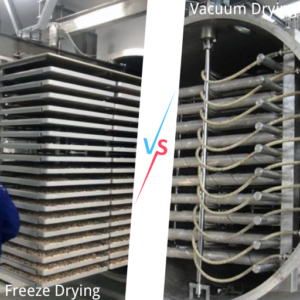

How does freeze drying differ from microwave vacuum drying?

Freeze-drying and microwave vacuum drying are separate methods that differ in their steps and results. Lyophilization, or freeze drying, occurs when the product is frozen. Then, the pressure around it is lowered so the frozen water can change directly from solid into vapor without becoming liquid first. This preservation method is known for conserving nutrients and shaping and tasting food. On the other hand, microwave vacuum drying involves the usage of microwaves under vacuum conditions to remove moisture quickly from items at low temperatures while retaining quality. Time and energy requirements are higher for freeze-drying than microwave-vacuum drying; however, freeze-drying is best suited to preserving the original form and keeping touchy things safe for long periods. Conversely, microwave-vacuum drying provides faster dry times and greater efficiency, allowing rapid moisture removal and energy saving in various applications where fast drying out is necessary, followed by cost reduction on power consumption.

The freeze-drying process is explained.

Freeze drying, also known as lyophilization, is a three-step process that includes freezing, primary drying (sublimation), and secondary drying (desorption). The product initially undergoes freezing to convert water into ice. In the primary drying phase, the chamber pressure is lowered, and heat is applied, causing the ice to sublimate directly into vapor. The remaining water molecules are removed by decreasing moisture content under low pressure and elevated temperature in the final step, called secondary drying. This method helps maintain the structural integrity, nutritional value, and taste of products; that’s why it is widely used in pharmaceuticals, the food preservation industry, and the biotechnology sector.

Comparison: microwave-assisted freeze-drying vs traditional freeze-dryer

Various vital elements become apparent when you compare microwave-assisted freeze-drying with traditional freeze-dryers. The reason for this is that microwave energy is used to hasten sublimation in microwave-assisted freeze-drying, which leads to a significant reduction in drying times. This quick energy transfer makes drying cycles fast, thereby improving the preservation of heat-labile compounds.

Conversely, traditional freeze dryers are recognized for their capability to create a stable and controlled environment necessary for preserving materials’ structural integrity, nutrients, and bioactivity. However, it consumes more time and energy.

Another factor that needs consideration is cost-effectiveness. However, microwave-assisted systems have low initial investments and wide application areas within industries. Reduced drying time and energy usage can save operational costs.

Speed and efficiency are their major selling points, especially when dealing with commercial ventures where every second counts, but attention to detail remains paramount to not compromise on quality. Traditional freeze drying still reigns supreme over others due to its ability to give high-level control over low-value products that may require fragile handling during production processes.

Evaluating efficiency: freeze drying and vacuum drying

To determine whether freeze drying or vacuum drying is more efficient, it is essential to look at drying speed, energy usage, and product quality, among other factors.

Speed of Drying and Energy Consumption: The steps involved in freeze drying usually make it take longer, including freezing, primary drying (sublimation), and secondary drying (desorption). This method needs a lot of energy because low temperatures must be maintained under vacuum conditions. Conversely, vacuum systems being operated at higher temperatures while moisture is removed from them through a low-pressure environment leads to quicker dry time and less power used compared to freeze drying.

Quality of Product: Freeze-drying has been best known for preserving delicate substances’ structural integrity, nutritional value, and bioactivity. Such an elaborate process ensures no loss in quality by preventing shrinkage while maintaining the original shape and texture. Contrastingly, vacuum dryers, though faster, can cause shrinkage or affect texture composition due to higher temperatures during dryness, making them unsuitable for heat-sensitive products.

Applications and Costing: Pharmaceuticals of high value, fragile foodstuffs, and research materials where quality stability counts most are among the areas where this technique is widely used. Even if operational expenses are higher when using such methods, long-term benefits realized through enhanced product qualities always outweigh these costs. Vacuum drier finds excellent application in situations prioritizing speed over delicacy, like bulk industrial settings; hence, they tend to be cheap on energy utilization.

In conclusion, freeze-drying saves on quality at the expense of time taken and the amount of energy required. Vacuum systems offer efficiency gains and reduced operational costs, albeit with compromised product quality, particularly on materials that cannot withstand heat. The decision between any two methods largely depends on what one wants from their items: efficiency or perfection.

What are the benefits of faster drying times achieved with microwaves?

Microwave drying has many advantages because it is faster at drying. To begin with, it cuts processing time by a significant margin, which can increase efficiency in production setups by putting in more work. Secondly, quick drying reduces the hours that products stay under heat, thereby protecting heat-sensitive nutrients and bioactive substances better than traditional ways, where they are left for long periods. Thirdly, fast drying also retains product texture, color, and general appearance, giving us an end product closer to its natural form than any other method would have done. Therefore, such strengths make microwave drying attractive for industries that need high output rates and produce good quality goods.

The impact of microwave power on process times

The power of microwaves influences process times because they directly affect how fast moisture is removed. More energy is supplied to the product at higher settings for microwave power, accelerating heating and evaporation of moisture. Nevertheless, there should be careful consideration since too much energy may overheat, thereby distorting quality attributes such as color, texture, or nutrient content of products; hence, it is essential not only to dry rapidly but also to ensure that these changes do not occur without damaging them. To this end, therefore, one must optimize their usage levels during drying not to compromise the integrity of items being processed through this method.

Mechanisms resulting in faster drying

There are different ways of achieving faster drying in microwave systems. The first method involves heating the materials that need to be dried by polar molecules, such as water oscillating rapidly due to being acted upon by microwaves. These waves cause the molecules to move back and forth at a higher frequency, which creates friction between them, thus generating heat in this process; moisture will, therefore, evaporate quickly from such products. It should also be noted that microwaving works effectively because it can go through objects for quite some distance, facilitating volumetric heating compared to surface-only heating used by other methods where only the outer parts get heated. This ensures uniformity in removing moisture throughout the material, resulting in quicker removal of water from it than traditional techniques would have achieved based on surface evaporation alone. Hence, fast internal warming coupled with effective elimination of humidity accounts for much shorter periods required for drying when employing microwaves, as indicated by their technology.

Analyzing drying times achieved with microwave technology

As a rule, microwave technology is much faster for drying things than other ways, such as air or freeze drying. It usually takes hours or even days to do it traditionally, but this can be reduced to minutes or hours with microwaves due to efficient inner warming mechanisms. That quickness of moisture elimination reaches ten times higher results if we use microwaving instead of any other ordinary processes. Such efficacy is explained by the fact that only this type of power may supply water molecules with energy evenly throughout the whole product, thus making its surface dry uniformly. Moreover, research indicates that when optimum power levels are applied, color and nutrients inherent in certain kinds of goods are conserved.

Can vacuum drying be an alternative to freeze-drying of biologics and vaccines?

Vacuum drying can be an alternative to freeze-drying for biological products and vaccines. It can work at lower temperatures than freezing, which helps to keep temperature-sensitive biomolecules stable. Moreover, vacuum drying takes less time and is cheaper than freeze-drying. Nevertheless, one should consider some points like the stability of certain biologics or vaccines, the possibility of oxidative degradation, and scaling up the drying process. Ultimately, if we optimize it correctly, vacuum drying seems an excellent way to save things like drugs or vaccines from living cells.

Case studies: freeze-drying of biologics and vaccines

Much has been learned about biologics and vaccine freeze-drying. These works have established that freeze-drying (lyophilization) is still the most effective way of ensuring stability and potency in temperature-sensitive bio-products. For instance, a study published on ScienceDirect explains how monoclonal antibodies can be preserved through their structural integrity and biological activity while being lyophilized along with other protein-based drugs. Similarly, an article from SpringerLink states that vaccines should be protected by cryoprotectants so that their constituents remain viable under various storage conditions for longer durations. Freeze-dried vaccines have a longer shelf life than those dried using different methods. Besides, they also show better immunogenicity when compared with other drying techniques. Together, these cases demonstrate how robust and reliable freezing dryness can be while still appreciating its use as a preferred method for preserving biologics and vaccines.

Exploring vacuum drying as an alternative option

Freeze drying has shown itself to be a contender in vacuum drying when it comes to preserving biologics and vaccines; this technique has some distinct benefits that should be investigated further. Vacuum drying, as described by top sources like ScienceDirect, SpringerLink, and MDPI, works by reducing the pressure around the substance so that water will boil at a lower temperature and evaporate. This can be faster than traditional freeze-drying and use less energy, too.

Vacuum dryers can significantly reduce thermal degradation because they operate at higher temperatures but lower pressures, which preserves heat-sensitive components’ stability. According to SpringerLink, vacuum dryers are known for maintaining biological activity in certain drugs while retaining protein structure and other complex molecule functions, sometimes even better than freezing them. In addition, MDPI mentions cost-effectiveness due to the simplicity of the equipment requirements needed for setting up vacuum dryer systems alongside reduced running expenses incurred during operation compared with freezers.

However good these results may seem, some precautions need to remain, like regulating pressure levels carefully lest quality standards are compromised during the drying process. Control must be exercised over parameters such as drying time and temperature if quality is not supposed to suffer. Sometimes, even more than one day can pass before everything completely dries out when using this method. To make vacuum drying an alternative method of freeze-drying in the biopharmaceutical industry, more research is required, coupled with optimization efforts over a long period.

Benefits of foofiologics and vaccines

- Better Stability and Potency: Vacuum drying is used in the production of biologics and vaccines, enabling the retention of stability and potency through reduction of thermal degradation and preservation of heat-labile compounds intact.

- Preserving Biological Activity: Another advantage is that this technique helps maintain biological activity; it ensures that proteins do not lose shape or function while being dried along with other complex molecules.

- Cheapness: Compared to freeze-drying, vacuum drying may be more cost-effective because it requires more straightforward equipment and involves less costly operation. Hence, it can be used for large-scale production without financial strain.

In general, vacuum drying offers advantages over traditional methods like freeze drying when handling biologics or vaccines, such as better stability, preservation of biological activities, and low costs.

How does simple modeling help identify a mechanism for faster drying times?

Faster mechanisms for drying can be identified using simple models. Such models simulate drying in different settings and under various conditions and parameters. Researchers can forecast how changing temperature, pressure, airflow rate, or humidity will affect moisture removal if they create mathematical models representing these variables as functions. Therefore, there is no need to conduct many laborious experiments because these equations allow optimal drying regimes to be found easily and quickly. In addition, modeling can point to places where things get stuck or go wrong during drying, thus giving ideas on what should be adjusted for better efficiency in speed and uniformity across all parts being dried. Ultimately, it seems that simplicity itself may sometimes serve best regarding technological advancement relating to drynesses.

The role of modeling is to identify a mechanism in drying processes

Modeling is crucial in drying processes because it helps identify mechanisms by giving a framework for predicting and analyzing materials’ behavior at different drying conditions. Various scenarios can be simulated, and the effect of temperature, humidity, and airflow on drying rate is understood through computational and mathematical models.

Insights from the top websites:

- ScienceDirect: Simple modeling creates equations or simulations that represent the dry process. Such models help to identify critical parameters that affect drying rates and allow for optimization of these parameters to achieve faster and more efficient drying.

- MDPI: Modeling significantly reduces the need for extensive experimental trials. Models simulate drying processes, revealing insights into moisture transport mechanisms and suggesting areas where process adjustments can be made, such as changing temperature or airflow.

- Elsevier: Advanced modeling techniques can handle the complexity of different materials during their interaction while they are being dried. Therefore, researchers can know which factors need to be altered to improve efficiency in targeting specific points to enhance drying technologies with better results.

No system can be optimized without understanding how it works when moisture is removed from it (drying). Thus, modeling is indispensable during these times, leading to shorter development periods and higher efficiencies.

Examples of effective s, simple dealing to identify drying mechanisms

- ScienceDirect: For instance, basic models can identify parameters such as temperature, humidity, and material characteristics that influence drying rates. These models simplify the optimization process so efficient drying conditions can be achieved quickly.

- MDPI: Moisture transport in materials may be simulated using lumped parameter models or finite element analysis (FEA), among other simple computational methods. This allows one to understand how content changes over time and where improvements are possible in processes like adjusting airflow or setting temperatures more precisely.

- Elsevier: It shows us what materials do while they dry when we use basic models; this includes drying kinetics and phase equilibrium principles based on simple assumptions about mass transfer rates between phases during drying. These model types also allow us to find out what exactly needs changing for faster overall improvement in efficiency. Such examples include initial moisture content and drying medium conditions.

These websites have all shown that using uncomplicated but effective models will significantly help us better understand and improve different drying systems.

What is the effect of microwave radiation on the drying method?

The drying process is powerfully influenced by microwave radiation, which speeds it up and makes it more energy-efficient. What distinguishes microwave radiation from traditional drying methods is that the latter depends on heat transfer across the surface and diffusion of moisture within materials, whereas microwaves generate volumetric heating. This means water evaporates more quickly due to inner heat; temperatures become even throughout, and drying takes less time. Moreover, such a technique can save valuable compound characteristics by reducing thermal damage during processing stages for dried products. In summary, this method of wave exposure is faster than others while being equally effective at removing moisture content from foodstuffs or other goods – but without spoiling their quality features like taste or appearance, unlike various common approaches.

Understanding the effect of microwave radiation

- ScienceDirect: Microwave radiation speeds up the drying process by heating quickly and evenly, removing moisture faster, and maintaining material quality. It can heat inside directly, significantly shortening the overall time consumed for drying with no overheating on the surface.

- MDPI: Microwave drying creates a uniform drying environment, which leads to consistent product quality and reduces processing time. Microwaves have high energy efficiency since they directly penetrate water molecules in materials, thus traditional drying methods.

- Elsevier: Microwave radiation during drying helps enhance the kinetics involved, leading to increased overall drying rates while maintaining product integrity. Moisture is removed uniformly because microwaves heat volumetrically, reducing the chances of structural damage occurring in any part of the object.

In summary, wave oven waves improve dryness by speeding up evaporation through even heating, saving energy and simultaneously preserving physical properties.

The interplay between microwave heat and moisture removal

In a procedure to get rid of water from materials, microwaves heat them by acting on the molecules made up of them. Such contact is responsible for fast and even heating all over the substance, thereby speeding up evaporation rates. According to ScienceDirect, this technique prevents overheating at the surface while ensuring early moisture removal. MDPI shows that microwave drying creates a uniform drying environment, thus reducing processing time and saving energy. Also, Elsevier adds that microwaves uniformly remove moisture due to their volumetric heating mechanism, which lessens the chances of destroying structures. All these references can be summed up as saying that when heat interacts with removing moisture using microwaves, it becomes efficient and retains quality throughout the drying process.

Long-term effects on product viability and quality

In the long run, drying by microwave has been shown to affect different products’ viability and quality positively. ScienceDirect says microwave-dried goods have more essential nutrients and bioactive compounds than traditionally dried. This ability to keep back nutrients is fundamental for preserving food items for a long time and maintaining their nutritional value. Another thing that MDPI notes is rapid even heating during this process, which it claims helps maintain structural soundness while retaining sensory properties such as color, texture, and taste, among others. Elsevier backs up these findings, saying that heat-labile substances are less degraded when products are dried using microwaves, thereby keeping them functional for extended periods without spoiling their qualities. All these sources imply that microwave drying increases efficiency and supports continuous quality improvement and the sustainability of dried products.

Frequently Asked Questions (FAQs)

Q: What is microwave vacuum drying?

A: Microwave vacuum drying is a complicated method that matches microwave radiation with a vacuum environment to remove moisture from materials faster. This technique uses microwave radiation to heat the material from within while an air pump lowers the pressure outside, thus making it dry quickly.

Q: How does microwave vacuum drying compare to traditional freeze drying?

A: Compared with traditional freeze-drying methods, microwave vacuum drying may be faster, as there is a significant decrease in time spent on this process. To perform conventional freeze-drying, water is frozen, and then the ambient pressure is reduced to enable it to sublimate into the vapor phase. On the other hand, in comparison with microwave freeze-drying, both heat produced through microwaves and vacuum conditions are used for quicker elimination of moisture.

Q: What are the advantages of using microwave vacuum drying?

A: Employing microwave vacuum drying has many merits. These include shortened drying time, better color and nutrient preservation, and the capability to dry various materials at different microwave frequencies for better outcomes. Such advantages can result in increased efficacy and improved product quality.

Q: What role does simple modeling play in microwave vacuum drying?

A: Simple modeling is beneficial in identifying drying characteristics and mechanisms during microwave vacuum drying. Through simple modeling, engineers can understand how materials respond to microwave radiation and vacuum conditions, thus enabling them to optimize equipment settings for different types of materials that are being dried.

Q: Are there any notable reports on microwave vacuum drying?

A: The first report on using microwave vacuum drying showed that it can enhance drying efficiency by a significant margin over usual methods. The following studies have probed into the reactions of different materials to microwave vacuum drying, thus establishing its efficacy and benefits.

Q: How is the vacuum chamber used in microwave vacuum drying?

A: In microwave vacuum drying, the chamber is significant because it lowers atmospheric pressure around the dried substance. Consequently, this reduced pressure enhances the quicker elimination of moisture and enables water to evaporate at lower temperatures, which prevents heat damage to thermally sensitive substances.

Q: How does microwave vacuum drying impact different materials?

A: Microwave vacuum drying is not the same for all materials. The moisture content and thermal sensitivity are the material’s traits that can modify this effect. One can dry things quickly without spoiling their quality by changing the power and frequency of microwaves and the pressure inside a vacuum chamber.

Q: Can microwave vacuum drying be used for delicate materials?

A: Yes, high temperatures may destroy delicate items, so they must not be exposed to them during this process. Evenly dried throughout, sensitive objects keep their shape better and preserve nutrients. Hence, these conditions can be created with microwaves’ control over power utilization and vacuums that are gentle on fragile elements’ structures while ensuring uniformity.

Q: What industries benefit from microwave vacuum drying?

Various industries drive businesses that benefit from exploring the drying technique using microwaves. These include food processing, pharmaceuticals, and biotechnology. These areas demand gentle yet effective ways of drying that will not compromise the quality or potency of heat-sensitive products.

Q: How does microwave vacuum drying influence the drying characteristics of materials?

Microwave vacuum drying affects how materials dry through fast and even heating. This approach guarantees homogeneity in water elimination throughout a substance, thereby playing a vital role in maintaining the standard of goods while preventing unevenness during drying or thermal harm.