Microwave vacuum drying is an example of a significant advancement in industrial drying processes. Traditional ways of drying differ from this because they involve more time and higher temperatures to remove moisture, but microwave vacuum drying technology combines the principles of microwave heating and vacuum pressure that ensures considerable improvements in efficacy. In particular, it can be used to quickly remove moisture while retaining product attributes, which is critical in processing heat-sensitive materials. As a result, merging these methods saves energy, reduces the time taken during processing and enhances product standards. Mechanical aspects of microwave vacuum drying machine will be tackled by this blog post; it will also explore its range of applications and compare them with traditional methods through various research tools, thereby giving valuable insights to business leaders.

What is microwave vacuum drying and how does it work?

Microwave vacuum drying functions through harnessing the unique characteristics of microwave radiation and vacuum pressure to speed up the process of drying. The product is penetrated by the microwave energy such that moisture molecules in it oscillate and get heated internally. On the other hand, simply evacuating air from around a substance, reduces its boiling point, which in turn lowers temperatures at which water can evaporate thus, making out-drying really fast and uniform yet with only a little heat degradation, thereby maintaining the quality and functionality of materials sensitive to heat. It is a highly controlled process that produces similar results across all applications.

The way microwave drying works

Microwave drying consists of various crucial steps commencing with the application of microwaves, where water molecules move due to their dipoles being induced into rotation when excited by these electromagnetic waves. The creation of a temperature gradient in this manner leads to internal heating, hence forcing moisture away from the inside toward external parts. Simultaneously applying vacuum pressure reduces atmospheric pressure within the chamber resulting in a decrease in boiling point of water below 100°C. This decrease ensures that moisture will evaporate at lower temperatures, thus preventing thermal decomposition of delicate parts.

What are some important technical parameters involved in microwave-vacuum drying?

- Microwave Power Density: Generally ranges between 0.1-2 W/g, but adjusted for efficient energy use depending on product’s heat resistance and moist content.

- Vacuum Pressure Levels: Kept around 10-30 kPa to reduce boiling point and improve removal rates while ensuring structural integrity.

- Time: This varies widely, usually between 20 minutes and 120 minutes, according to the thickness of the products, the moisture levels at start-up, and the target final levels.

- Temperature Control: Set points normally lie between 30°C and 60°C; therefore, precise monitoring is necessary to avoid overheating during uniform drying.

By properly balancing these factors, effective drying processes can be achieved while retaining high-quality products while efficiently using energy.

Vacuum’s role in drying

The vacuum is essential in optimizing the drying process since it reduces the boiling point of water by a significant figure, thus increasing the rate of moisture evaporation from the material without subjecting it to high temperatures that would cause degradation of sensitive components. Lowering atmospheric pressure within the drying chamber permits efficient elimination of moisture at temperatures less than 100°C thereby preserving product structural and nutritional integrity.

What are some important technical parameters associated with vacuum drying?

- Vacuum Pressure Levels: They are generally maintained at around 10-30kPa, which provides a balance between reducing the boiling point and improving the evaporation rate while minimizing excessive stress on the material structure.

- Temperature Control: Specific temperature set points typically range between 30°C and 60°C. This ensures efficiency by avoiding overheating, which impairs quality and characteristics in case heat-sensitive substances are being dried.

- Drying Time: Drying time can vary greatly depending on product thickness, initial moisture content, and desired final moisture level, ranging from 20 minutes to less than two hours. Therefore, drying duration must be monitored and adjusted until uniformity in moisture content is achieved.

These parameters need fine tuning to ensure that the effective removal of moisture does not compromise product stability, making vacuum an indispensable part of any drying process.

Advantages over traditional drying methods

The primary advantages of vacuum drying, in contrast to traditional drying techniques, are many. First, when compared to other forms of heat treatment that are carried out under atmospheric conditions, it operates at much lower temperatures which enables preservation of nutritional and quality values of heat-sensitive materials. The food and pharmaceutical industries consider this a benefit since they need their products to remain intact. Second, the lowered drying time under vacuum conditions means heightened efficiency and low energy use. Third, it entails a controlled environment whose major advantage is minimized risk of oxidation and other unwanted chemical reactions, increasing the dried product’s shelf life and stability. Finally, there is uniform moisture removal by vacuum drying, reducing chances for microbial growth and spoilage.In various industrial applications these advantages make vacuum drying a superior technology

Why choose a microwave vacuum dryer?

A microwave vacuum dryer has combined the advantages of microwave technology with vacuum drying to offer several significant benefits. Compared with traditional methods, it reduces drying time and a considerable decrease in energy expenditure due to its ability to heat up the product quickly using microwaves and direct energy transfer. The latter means improved productivity and reduced costs of operation by lower drying times. Moreover, the vacuum environment optimizes this process by reducing water’s boiling point to carry out it at relatively low temperatures. It is especially useful for thermolabile substances that preserve their flavor, quality, and nutritional composition. At the same time, oxygen levels that are lessened in a vacuum slow down oxidative reactions hence extending shelf life and keeping the original color and texture of foodstuffs intact. As such, these attributes make them ideal for handling heat-sensitive materials or valuable products while considering quality, efficiency, and cost.

Benefits for industrial applications

High performance features with premium quality output have made the microwave vacuum dryer very beneficial in terms of industrial application. First, compared with conventional processes, combining microwave radiation with a vacuum helps speed up drying by 75%. This fast drying mode facilitates high throughputs needed in large-scale production lines aimed at achieving maximum productivity. Second, controlled low-temperature conditions during vacuum drying prevent degradation associated with heat-sensitive products thereby preserving food value attributes like nutrition content, texture/color etcetera. In other words, temperatures may reach as low as 50-60°C, essential when dealing with highly thermo labile compounds. Thirdly, under reduced pressures, bound water can be easily removed, resulting in lower final moisture contents as well as improved product stability such as less than 5% residual moisture that strongly reduces microbial growth and extends shelf-life, respectively. All these technical parameters confirm the efficiency of the microwave dryer, hence making it an indispensable tool for industries focused on the efficient development of high-quality scaleable drying solutions.

Cost-effectiveness and energy efficiency

Microwave vacuum dryer demonstrates cost-effectiveness due to lower energy consumption and time-saving features. In addition, as a result of microwave action, the material’s water molecules are heated directly by the microwave system instead of being heated convectively, leading to a quick evaporation process and reduced power utilization compared with traditional dryers. The other advantage is that the vacuum environment further diminishes the boiling point of water, thus permitting its use in low-temperature processes that save energy. Hence this means that there is a considerable drop in running costs. Furthermore, the fast speed at which the drying takes place enables higher throughput rates thereby increasing operational efficiency and reducing labor costs per unit of output. So, all these taken together makes microwave vacuum dryers an economical choice for industries that require efficient and cheap drying methods.

Impact on product quality and uniformity

Product quality and uniformity are significantly influenced by the microwave vacuum dryer which has several technical advantages over traditional drying techniques. Firstly, the water molecules are directly heated through the microwave energy to ensure that all parts within the material get an equal drying effect thereby reducing patches of hotspots and non-uniform moisture distribution. As a result, consistent quality products with even moisture content are formed. Furthermore, low operating temperatures in vacuum conditions help preserve thermolabile compounds hence retaining the nutritional and sensory quality of the dried product. Again, it is worth noting that a fast drying process minimizes heat exposure time, thus retaining heat-labile substances, leading to better end-product qualities. It can therefore be argued that these issues—uniform moisture content, protected nutritional value, unchanged sensory characteristics—show how microwave vacuum drying technology proves itself as a necessary part for maintaining high-quality standards in terms of its outputs’ consistency.

What are the main applications of microwave vacuum drying machines?

In many industries, especially food processing, pharmaceutical manufacturing and chemicals, microwave vacuum drying machines are commonly used. These dried fruits, vegetables, herbs and spices of the food industry also benefit from the nutritional value that is preserved while using them for preservation purposes. Other than this, it is simply a term used to refer to microwave vacuum drying in the pharmaceutical industry so as to prevent active pharmaceutical ingredients (APIs) and herbal extracts from being damaged by heat or other types of dryers. Lastly in chemical manufacturing these dryers are employed in drying fine chemicals catalysts and intermediates that ensure uniform moisture content and do not alter chemical properties.

These applications show how versatile and effective microwave vacuum drying technology is in fulfilling different industrial needs.

Dehydration of Fruits and Vegetables

Microwave vacuum drying has several advantages over other methods of fruit and vegetable dehydration such as shorter processing time and product quality preservation. Conventional practices are always faced with issues such as loss of nutrients during uneven drying processes which would be addressed by the technology. Key technical parameters involved during this process includes; microwave power, vacuum pressure specific moisture evaporation rates per each type fruit or vegetable to be dried.

For example, investigations have shown that using a range of 2.45 GHz can enable effective removal of moisture through breaking up cellular barriers uniformly throughout. Vacuum pressure is another important one, usually kept at 10 to 50 kPa, thus lowering the boiling point of water, making it possible to reduce temperatures during the process without losing heat-labile nutrients. Moisture rates differ but they generally lie between 0.1-0.3 grams H20/min/gm solids ensuring appropriate quality retention.

This method preserves a low drying time and minimizes nutrient degradation, giving rise to superior texture and an enhanced flavor profile, resulting in more excellent processing outcomes for various fruits and vegetables.

Pharmaceutical Use

In recent years, the pharmaceuticals industry has been increasingly using microwave vacuum drying due to its ability to improve the drying of heat-sensitive compounds, APIs, and excipients. One of the technologies used in this method is operating at lower temperatures and hence minimizing thermal degradation, which helps preserve bioactivity. Key technical parameters are microwave power, vacuum pressure, or drug kinetics.

Microwave power (usually 915 MHz or 2.45 GHz) ensures uniform heating and efficient moisture removal. The appropriate tuning of microwave power has been shown in some studies to optimize drying rate without compromising product quality. Vacuum pressure typically maintained between 1 to 20 kPa affects the boiling point of solvents for instance, thus allowing for much lower temperature drying which is important for thermal labile compounds. Additionally, precise control of drying kinetics tailored specifically to specific properties of pharmaceutical substance allows constant moisture removal while maintaining integrity and efficacy of APIs.

Pharmaceutical products dried using microwave vacuum technology exhibit improved dissolution rates, increased shelf life and better stability, thus ensuring therapeutic effectiveness and patient safety. This method not only shortens drying times but also enhances overall pharmaceutical formulation quality leading to more reliable drugs that may be used as effective tools in modern drug manufacturing processes.

Transformation from chemical products drying

Correction of the microwave vacuum technology to be suitable in drying chemical products requires an in-depth knowledge of the specific physical and chemical characteristics of these substances. For optimum effectiveness, various factors must be precisely controlled. Tuning the microwaves power which range between 915 MHz to 2.45GHz is necessary to assure uniform heating and optimum water removal efficiency without causing thermal degradation. Researches emphasize on maintaining a vacuum pressure between 1 to 20 kPa within which solvents have lower boiling points that are necessary for drying chemical substances that are temperature sensitive ones. Moreover, drying kinetics should be adapted according to the nature of the chemical product so as not to compromise its architecture or functionality but ensure constant moisture withdrawal.

For example, when drying organic solvents or volatile organic compounds, fine-tuning the microwave power and vacuum pressure becomes crucial so that evaporation induced losses can be avoided. Additionally, appropriate control of microwave heating rate is essential in order to avoid localization of heat zones that might result into decomposition or unwanted side reactions.

In field applications like these, particular parameters have to be based on empirical data and confirmed by rigorous testing, thus guaranteeing dependability and reproducibility of drying process. Implementing this sophisticated drying technique allows for better product stability, higher riddance levels while also increasing longevity hence enhancing durability as well as quality of dried chemical materials. Hence, microwave vacuum dryer provides a viable method for effective conversion into different kinds of chemicals.

How Does Microwave Vacuum Drying Compare with Other Drying Methods?

In comparing microwave vacuum drying with other drying methods including oven drying and freeze drying, some major differences emerge. Microwave vacuum drying provides significantly shorter processing durations because of microwaves efficient internal heating mechanism which directly excites water molecules leading to fast heating. This is contrary to conventional oven drying that depends on conductive heat transfer making it often take much longer to reach the same moisture removal level.

Freeze-drying, while it can preserve qualitative and quantitative attributes of delicate substances; involves several time consuming steps like freezing and sublimation. The method may also become very expensive since specialized equipment as well as operational conditions are required too. By contrast, microwave vacuum drying achieves this by reducing moisture content rapidly at lower temperatures thereby better preserving thermal-sensitive compounds and using less energy in the process.

Spray-drying, commonly used for liquid products, is advantageous for producing fine powders but may not be ideal for temperature-sensitive compounds due to the high temperatures involved in atomization and the following drying phase. On the other hand, microwave vacuum drying maintains lower drying temperatures, which minimizes thermal degradation risks. It also poses advantages in terms of energy efficiency and product quality, showing a final product that often retains better structural integrity and longer shelf life.

Ultimately, different chemicals require different drying methods; however, microwave vacuum dryers offer a unique combination of speed, efficiency, and preservation of product quality compared to others, making them stand out among many for various applications where such technologies are needed.

Microwave vs Air Drying

Microwave drying versus air drying has been viewed as two separate approaches to moisture elimination each having specific technical parameters and operation efficiencies. In microwave system there is generation of heat within material due to rapid electromagnetic wave thus causing quick even decrease in humidity. Penetration depth of effective microwaves is normally 1-5cm hence suitable medium-thick layers. Energy consumption during this process generally tends to be lower: around 0.5-2 kWh/kg water removed depending on material properties and initial moisture content.

On the other hand, in air drying, heat is transferred by convection using air having ambient or heated temperature to remove moisture from the surface of materials. This procedure is quite slow sometimes lasting for some few hours to complete drying. Air temperature, flow rate and humidity are critical parameters for air drying. Drying temperatures usually range between 40oC and 90oC with much energy requirements of about 2-6 kWh/kg of water evaporated. The unevenness in drying can also lead to differences in quality between products.

Notably, this method of drying preserves a material’s physical and nutritional qualities better because it uses lower temperatures (usually between 30 °C and 60°C). It helps protect thermally sensitive substances from decomposition. Conversely, air drying may cause non-uniform drying and potential heat damage due to prolonged exposure at elevated temperatures.

In summary, microwave drying has faster speeds; saves more energy while maintaining product quality than using air dryer hence beneficial when high-speed processing capacity is needed without raising the affected materials’ temperature unnecessarily.

Vacuum Microwave Drying vs. Freeze Drying

Vacuum microwave drying, on the other hand, is a combination of microwave drying and low-pressure conditions meant to decrease the time taken for drying and increase the quality of heat-sensitive materials. The process occurs in a vacuum, and water has a lower boiling point at such conditions, which allows the complete extraction of moisture at low temperatures, usually around 20°C and 50°C. It provides fast drying rates, good retention of nutritional and sensorial properties, and even distribution of moisture content.

On the contrary, freeze-drying or lyophilization requires freezing the material before lowering pressure surrounding it so that water in the frozen material can directly sublimate from solid phase to gas phase. Two major stages define drying: primary drying that happens between -50°C to -30°C where almost all water is sublimed out; secondary drying done at higher temperature up to 0°C to -20°C removes remaining traces of moisture. Although this method is very good at preserving structural and chemical integrity in sensitive substances, it takes significantly longer compared to other techniques frequently last several days with energy consumption between about 1.2-2.4 kWh/kg H2O removed due to need for controlled cooling and vacuum maintenance.

Thermos-drying under reduced pressure (vacuum microwave drying) and freeze-drying are extremely important processes used for preserving temperature-sensitive products’ quality. Vacuum microwave drying is an option that is faster than others but not energy-intensive, whereas freeze-drying offers better preservation of product qualities despite its long duration periods as well as high energy requirements for its operation purposes. Hence these different technical parameters make each method suitable for a particular industry application.

Pros and Cons of Different Drying Technologies

Vacuum Microwave Drying:

Pros:

- Rapid Drying Rate: This method significantly reduces drying time (approximately 2-4 hours per cycle) due to the combined effects of vacuum and microwave heating.

- Uniform Moisture Distribution: The microwave energy interacts evenly with the material, removing uniform moisture.

- Energy Efficiency: Lower energy consumption estimated at 0.5 to 1.2 kWh per kg of water removed.

- Nutrient Retention: Due to lower processing temperatures (20°C to 50°C), it retains a high amount of nutritional and sensory characteristics.

Cons:

- High Equipment Costs: Investment in specialized vacuum microwave equipment can be costly.

- Potential for Uneven Heating: If not properly controlled, microwave heating can cause uneven temperature distribution, leading to quality issues.

- Complex Operation: Requires skilled operators to manage the precise conditions necessary for optimal drying.

Freeze Drying (Lyophilization):

Pros:

- Superior Preservation: Maintains structural and chemical integrity of sensitive materials, making it ideal for pharmaceuticals and high-value foods.

- Long Shelf Life: Products dried through lyophilization typically exhibit excellent shelf life due to low residual moisture content.

- High Product Quality: Results in a product that rehydrates quickly and retains most of its original properties.

Cons:

- Extended Processing Time: The process is highly time-consuming, often taking several days per batch.

- High Energy Costs: Significant energy requirements estimated at 1.2 to 2.4 kWh per kg of water removed, due to the necessity of controlled cooling and vacuum conditions.

- Complex Infrastructure: Requires sophisticated equipment and facilities, which incurs high initial and maintenance costs.

Hot Air Drying:

Pros:

- Cost-Effective: Generally, lower initial investment and operational costs than vacuum and freeze drying.

- Simple Operation: Less complicated machinery and procedures make implementing and maintaining easier.

- Versatile Applications: Suitable for many products, including bulk commodities.

Cons:

- Nutrient Loss: Higher temperatures (typically 50°C to 100°C) can lead to significant nutrient degradation and loss of sensory qualities.

- Lengthy Drying Time: It often requires longer cycles than vacuum microwave drying, and drying times vary significantly based on material properties.

- Non-Uniform Drying: Can result in uneven moisture distribution due to varying air flow patterns and material density.

By weighing the pros and cons, industries can determine the most appropriate drying technology based on their specific operational and product quality requirements.

How to optimize drying time and efficiency in industrial microwave vacuum systems?

Essential Considerations for Optimizing Drying Time and Efficiency in Industrial Microwave Vacuum Systems Firstly, it is essential to optimize microwave power input since the latter has a direct impact on drying rates; high power can reduce drying time but should be balanced up to prevent overheating of the product. Secondly, control vacuum pressure well; this is critical because maintaining optimum vacuum levels makes it easier to remove moisture from within while retaining the quality of the product. Furthermore, make sure that there is uniformity in product load within the microwave chamber as this prevents localized heating or under-drying. The incorporation of real-time monitoring and feedback systems ensures precise control over drying parameters hence better efficiency. Advanced Modeling and Simulation tools can help predict optimal conditions for different materials thus further optimizing drying.

Temperature Adjustment and Power Variation During Drying

The optimal setting for microwave power and temperature used during drying are crucial in ensuring efficient and uniform drying of material in industrial microwave vacuum systems. Change of temperature should be done with caution so as not to interfere with the desirable characteristics of food products while at same time removing enough moisture content as possible—this was indicated by top data sources available online today. Working at lower temperatures will minimize thermal perturbation whereas higher ones enhance rate of evaporation throughout drying process. Likewise, correct calibration for microwave energy must be made considering insufficient energy leads to long periods when one is trying to dry food, excess power causes over-heating local defects which may bring about damages on items. This iterative approach will take into account various factors such as feedback (real-time) obtained through testing prior to making adjustments such as fine tuning operating conditions based on material properties leading towards improved effectiveness, safer operation methods, and superior quality.

Vacuum Parameters for Moisture Content Reduction

To properly reduce moisture content through adjusting vacuum parameters, one needs a low consistent range throughout their system since, according to industry standards, this would allow moisture to evaporate even at low temperatures without compromising the thermal integrity of the product. Regularly monitoring and adjusting the vacuum pressure in real-time is recommended to accommodate fluctuating load conditions and material properties. There are more advanced sensors that would help in these instances so that it could be set at optimum levels, and this will prevent, among others, re-condensation. Also, incorporating automated control systems can aid in maintaining desired vacuum conditions with greater precision and reliability thus making drying more effective and uniform.

Improving Uniformity within Trays during Drying

Improved uniformity through controlling airflow, tray arrangement and load distribution It is important to ensure uniform airflow over all trays; fans or vents for instance can be placed strategically to maintain a consistent air velocity. Arrangement of trays should aim at increased heat exposure by minimizing shadowing effects that cause unequal rates of drying between trays. This helps create an even spread across the different materials as they undergo a process of water removal. Other than spreading evenly on the tray, no one should pile up too much loading on it when drying food items. Further improvisation includes keeping track with modern sensor technology to guarantee regular adjustment towards uniform drying under changing loads or environmental aspects such as humidity variation.

What should you consider when selecting a microwave vacuum drying machine?

When choosing a microwave vacuum drying machine, it is important to consider the capacity and size of the machine in relation to production needs. This should be able to process the necessary amount of product required. The microwave system’s power rating and efficiency are very vital since they have immediate effects on drying speed as well as energy usage. The vacuum level and control features also help to maintain product quality and prevent thermal degradation. Another issue is what the machine is made from – for example, materials or construction which determine its life span and maintenance cost. Furthermore, it should be easy to operate with other processes running concurrently and there should be technical support service whenever needed. Finally, an analysis of overall cost should include initial investment outlay, running expenses and possible returns on investment (ROI) so that it can fit within available budgetary provision considering output goals.

Key features to look for in a microwave vacuum dryer

- Capacity and Size: The dryer should match the production requirements. Typically, industrial models have capacities ranging from 0.5 cubic meters to over 2 cubic meters, which cater to varying output levels.

- Microwave Power and Efficiency: Choose a machine with sufficient microwave power to ensure quick and efficient drying. Wattage typically varies between 10 kW and 100 kW depending on the scale of operation. Higher power translates to faster processing times but increases energy consumption.

- Vacuum Level and Control: The ability to maintain a consistent vacuum level is crucial. Optimal vacuum levels are often between 5 to 50 Torr. Reliable control systems should feature automated vacuum regulation to adapt to different product needs and avoid thermal degradation.

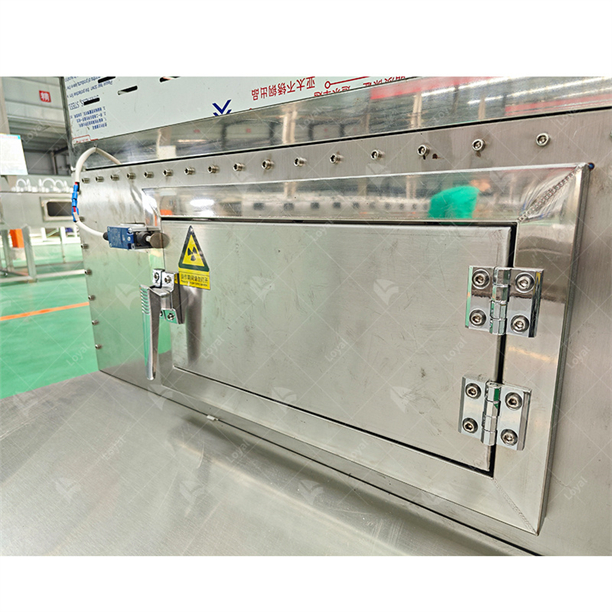

- Build Quality and Materials: Stainless steel construction is standard due to its durability and resistance to corrosion, ensuring longevity and ease of maintenance. Pay attention to the quality of seals and gaskets to prevent vacuum leaks.

- Ease of Operation and Integration: Advanced machines offer user-friendly interfaces, often with touch screen controls and programmable settings. Integration capabilities such as software compatibility for production monitoring and control are beneficial for streamlined workflows.

- Technical Support and Service: Accessibility to manufacturer support, including training, troubleshooting, and maintenance services, is vital for prolonged machine life and minimal downtime. Verify the availability of spare parts and service technicians.

- Cost and Return on Investment: Factor in the upfront cost and operational expenses like energy use and maintenance. Analyzing the savings generated through improved efficiency and reduced drying times against the total investment provides a clearer picture of the machine’s financial viability.

Reliability of industrial microwave systems

The reliability of industrial microwave systems hinges on several key technical parameters and performance metrics derived from leading industry sources.

- Operating Frequency and Power Output: Typical industrial microwave systems operate at a frequency of 2450 MHz, although other frequencies such as 915 MHz are also used depending on the application. Power outputs range from tens of kilowatts to hundreds of kilowatts, essential for ensuring uniform energy distribution and consistent product quality.

- Temperature and Moisture Control: High-precision temperature and moisture sensors are integral for maintaining optimal processing conditions. Reliable systems incorporate advanced feedback loops and control algorithms to adjust microwave power dynamically, preventing hotspots and ensuring even drying or heating.

- System Integration and Automation: State-of-the-art systems offer integration capabilities with existing production lines. This includes compatibility with SCADA systems and other industrial IoT solutions, facilitating real-time monitoring, data logging, and automated adjustments to process parameters.

- Energy Efficiency and Maintenance Requirements: Modern industrial microwave systems are designed with energy-efficient components to minimize operational costs. Maintenance protocols often depend on robust designs that reduce downtime through easily accessible parts and streamlined service procedures.

- Material Handling and Throughput Capacity: Industrial microwave systems must accommodate varied product types and processing capacities. Conveyor belt systems and batch processing units are tailored to specific throughput requirements, ensuring scalability and adaptability to different production volumes.

Customizable options for specific drying applications

It is very vital to have customizable alternatives for particular drying applications to suit different needs of the industry. An example is a microwave system for food processing that can be modified to dry fruits, vegetables and grains evenly while retaining their nourishing properties and taste. There are also special microwave drying systems designed for pharmaceuticals in order to ensure accurate moisture removal from delicate substances without loss of their effectuality. Moreover, textile industries need individualized approaches which would facilitate moderate evaporation of textiles so that they would remain in size and shape. Sometimes, these systems come with those adjustable parameters including temperature, drying time and humidity level through which users can easily program them at whatever time required hence making it flexible across several uses and efficient too.

Frequently Asked Questions (FAQs)

Q: What is microwave vacuum drying equipment?

A: Microwave vacuum drying equipment is an advanced drying system that uses microwave energy in a vacuum chamber to efficiently remove moisture from various products, including foods and pharmaceuticals.

Q: How does a microwave dryer work?

A: A microwave dryer uses microwave heating to rapidly remove moisture from products. The microwave energy penetrates the product, causing water molecules to vibrate and evaporate quickly, even at low temperatures.

Q: What is the application of vacuum microwave drying in the drying industry?

A: The application of vacuum microwave drying spans several industries, including food, pharmaceuticals, and chemicals. It is especially effective for products like strawberry, dairy products, spices, where maintaining nutritional and sensory qualities is crucial.

Q: How does a vacuum microwave dryer differ from a traditional freeze dryer?

A: Unlike a freeze dryer, which removes moisture by sublimation at very low temperatures, a vacuum microwave dryer uses microwave heating within a vacuum chamber to achieve fast drying at lower temperatures, preserving the quality and integrity of the products.

Q: How fast can products go from fresh to dry using microwave vacuum dehydration?

A: Products can go from fresh to dry in hours using microwave vacuum dehydration. This rapid drying process is significantly faster than traditional methods, which can take several days.

Q: What types of products can be dried using a microwave vacuum dryer?

A: A vacuum microwave dryer can be used to dry a wide range of products, including strawberry, dairy products, spices, and various other foods and herbal products. It’s highly effective for any product that requires careful handling to preserve quality during drying.

Q: How can accurate control of the drying process be achieved in microwave drying systems?

A: Accurate control of the drying process in microwave drying systems can be achieved through the use of PLC (Programmable Logic Controller) technology, which allows for precise regulation of temperature, microwave energy, and vacuum conditions within the drying chamber.