Hygiene has significantly developed in recent years due to advanced sterilization technologies. Among them is the microwave sterilizer, which represents a milestone in innovation. In this case, microwave energy is harnessed to kill harmful microorganisms efficiently on different surfaces including materials. The purpose of this paper is to examine microwave sterilization and explore how it functions compared with conventional means as well as its wide applications across a range of sectors, notably healthcare and food processing, to name some. Through the appreciation of such changes brought about by the introduction of microwave sterilizers, we can therefore have an insight on the importance of this tool towards safety and cleanliness within our daily undertakings.

What is microwave sterilization equipment?

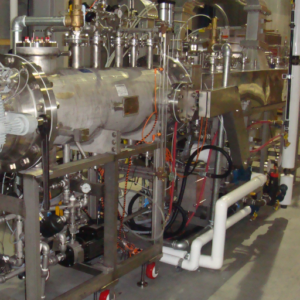

Image source: https://www.linkedin.com/

A microwaving sterilization device heats various things through microwave energy to make them reach the required temperature to ensure that it kills all forms of microorganisms, like fungi, viruses, and bacteria. The equipment includes a containment area where items are placed for sterilization, a microwave generator, and control systems to regulate the process. Alternatively, microwave sterilization is very effective and can disinfect materials evenly, unlike traditional methods, which involve chemical agents or exposure to high temperatures for extended periods. It is a practice that has found extensive application in healthcare, among other fields, such as food processing, as it ensures observance of elevated cleanliness levels.

Understanding microwave sterilization technology

The primary principle behind the operation of microwaves in sterilization is to generate microwave energy that is then taken up by water molecules within the items to be sterilized, and this absorption leads to rapid molecular vibration and friction, which results in heat, thereby killing microorganisms. It also guarantees uniform heating, so there are no cold spots where residual organisms might remain. In addition, microwave sterilization is faster and cost-effective compared to conventional techniques. This makes it ideal for use with heat-sensitive materials as a safe alternative to ensure that its contents are safe while maintaining the integrity of the material after being cleaned meticulously.

Benefits of using microwave sterilization machines

- Time Efficiency: Microwave sterilization saves time compared to traditional methods. The rapid heating ability of microwaves ensures that materials are sterilized in an instant, improving productivity.

- Energy efficiency: Microwave technology consumes less energy than conventional sterilization techniques. A targeted heating mechanism reduces energy wastage, making it a more sustainable and cost-effective method.

- Uniformity: Cold spots in materials that could be breeding grounds for microorganisms are eliminated by uniform heating provided by microwave sterilization. This guarantees the consistent disinfection of all parts of the article, thus improving overall safety and hygiene.

- Preservation of Material Integrity: Microwave Sterilization is particularly advantageous for heat-sensitive materials. It provides a reliable option for delicate instruments and products that would be damaged by extended exposure to high temperatures.

These benefits make microwave sterilizers ideal for industries ranging from healthcare to the food industry, where high levels of cleanliness are crucial.

Comparison with traditional sterilization methods

Microwave sterilization machines have several advantages compared to traditional methods of sterilization like autoclaving, chemical sterilization, and UV light sterilization:

- Speed: For instance, autoclaving takes a lot of time to attain the desired temperature for sterilization, while microwave sterilization does it within seconds, which makes it faster and more effective.

- Energy Consumption: Conventional ways such as autoclaving consume significant energy through an extended heating process. On the other hand, microwave sterilization targets areas requiring less power, making it economical and eco-friendly.

- Effectiveness: Though chemical methods can be very useful in sterilization, they might leave some harmful residues on materials or users. In contrast, when using microwave irradiation, all parts are evenly heated, minimizing cold spots where microorganisms may survive, meaning better and more predictable disinfection without chemical residues.

- Material Compatibility: Traditional procedures cannot use heat-sensitive materials because of their high temperature. Microwave processes, however, can save these kinds of materials so that they can be used safely with fragile instruments or products.

Overall, microwave-based sterilizing equipment is more efficient than many conventional ones in terms of energy consumption, heat distribution uniformity, and preservation of material integrity.

How does a microwave sterilizer work?

The microwave sterilizer emits microwaves, a sort of electromagnetic wave, towards an inner chamber containing the items to be sterilized. These waves make water molecules inside these or shake vigorously in a few added drops of water, causing them to become hot quickly. Steam is generated rapidly at high temperatures, eliminating bacteria, viruses, and other organisms. The Microwave radiation ensures that the heat is distributed evenly; thus, cold spots are reduced, and sterilization occurs uniformly. This process is regulated by setting time and power levels, making it efficient and user-friendly.

Principles of microwave energy in sterilization

Sterilization is all about heating water molecules in microwaves. Microwaves go into the material, interact with its polar water molecules, and make them oscillate speedily. Consequently, the entire material heats up evenly through this molecular motion. The heat generated can kill bacteria, viruses, and other microorganisms, making sterilization possible. It is also practical because it addresses outside and inside contaminations by erasing cold spots. Thorough disinfection that maintains the integrity of items is guaranteed by microwave sterilization, which employs exposure for specific periods of intensities under control.

The sterilization process is explained.

A microwave sterilization process is done by putting them inside the microwave sterilizer, along with a certain amount of water. When the oven is activated, some microwaves cause movement in water molecules, leading to steam production. In this case, steam gets all over them, and their temperature increases to unbearable levels for harmful microorganisms like bacteria, viruses, or even fungi. This procedure is usually brief and efficient due to its application of uniform heat distribution that leads to complete disinfection. Achieving constant and dependable outcomes for sterilization requires following the producer’s instructions on how much water should be used, together with time and the power settings needed. It offers an easy way of sanitizing different household items quickly; hence, it can be used by adjusting water levels based on manufacturers’ guidelines for reliable results in seconds.

Role of drying and sterilization in efficiency

The efficiency of the sterilization process can be increased by drying. Current top sources say that removing moisture from things before they are sterilized minimizes possible interference with the microwave energy so that the heat can concentrate well on target microorganisms. Drier things receive more uniform and faster warming, improving the process’s general effectiveness. Moreover, post-sterilization drying helps to preserve sterility and durability in sterilized items by preventing bacterial regrowth in residual moisture. Consequently, proper drying before and after sterilization ensures that the sterilization process is effective and reliable, thus making it a better option for routine disinfection needs in terms of efficiency or safety.

Applications of industrial microwave sterilization

Due to its efficiency and effectiveness, Industrial microwave sterilization is applied in different areas. For instance, the food industry uses it to kill pathogens and spoilage microorganisms while maintaining food products’ nutritional value and sensory qualities. Healthcare facilities also use microwave sterilization for quick and even sterilization of medical tools, thus reducing cases of cross-contamination. Moreover, the textile sector applies this method to disinfect fabrics and protective clothing. Equally important is its application in waste management, particularly where it disposes of medical- or hazardous trash. In general, industrial microwave sterilization is versatile enough to be used in various industries; hence, it is an essential tool for cleaning and safety.

Importance in food sterilization

The food industry needs industrial microwave sterilization because its swift and uniform heating annihilates spoilage microorganisms and pathogens. This method is used in food production to enhance the nutritional value, taste, and texture, which may be lost when standard cooking methods are used. This technique can minimize foodborne illnesses through prolonged sterilization as the shelf life of different food products is extended, reducing wastage and increasing safety. Moreover, microwave sterilization is a means by which energy consumption is reduced and environmental friendliness enhanced, making it a much sought-after approach for manufacturers of food who wish to obtain high levels of safety without compromising on quality.

Applications in pet food sterilization

The pet food industry depends on industrial microwave sterilization to ensure product safety and protection from harmful pathogens. Uniform heating with a quick pace permits the efficient eradication of bacteria and other microorganisms without compromising on the essential nutrients or flavors upon which pets depend. Consequently, this sterilization method helps reduce wastage and improve manufacturers’ inventory management by extending the shelf life of pet food. Additionally, this method is much more energy-wise than conventional methods; hence, it aligns with sustainable practices increasingly being demanded by the industry. This, thus, improves the overall quality and safety of products, giving peace of mind to pet owners.

Integration into production lines and conveyor belts

Optimum efficiency and uniformity of food processing operations are achieved by integrating microwave sterilization in production lines and conveyor belts. This method can be assimilated inexplicably into current production systems, leveraging cutting-edge technology to avoid interference. The continuous process nature of microwave sterilization reduces downtime and improves productivity. Automated controls and sensors monitor the sterilization process in real-time to guarantee adherence to safety regulations and quality checks. In addition, the small size of microwave sterilization equipment saves space on the factory floor, further simplifying work and raising overall effectiveness.

Advantages of microwave drying sterilization

Microwave drying sterilization has some advantages, making it an attractive choice in the food processing industry. These are:

- Quickness: This process is much faster than the usual way of drying and sterilizing, thus making more products to be processed within a shorter time.

- Same temperature heating: The microwave technology ensures the product is heated uniformly, eliminating cold spots that can act as shelter for bacteria.

- Efficiency in energy consumption: By using this method, less power is used, hence reducing operational costs.

- Nutrition and Flavor Preservation: Unlike most traditional methods, microwaving preserves food’s nutrients and flavor, thus enhancing its quality.

- Extended shelf life: Killing pathogens effectively enhances products’ shelf life and reduces wastage due to spoilage.

- Environmental gains: Minimizing energy consumption and reducing carbon emissions makes this method favorable for sustainable practices.

-

Space-saving design: Microwave ovens utilize minimal space, optimizing production floor layout with efficient use of facilities.

Time and energy efficiency of microwave drying

Remarkable time and energy efficiency are the characteristics of microwave drying. Raw material to finished product can be made in half the time compared to conventional drying methods, making it faster in its transition. This acceleration stems from the direct interaction between microwaves and water molecules in the product, leading to swift energy absorption. Moreover, microwave drying is carried out at lower temperatures, which retains product qualities and saves energy. For example, on an energy basis, microwave drying is much more efficient as it heats materials directly, thereby reducing losses of energy associated with heating surrounding air or equipment surfaces. It directly impacts lowering operational costs and carbon footprints for a more sustainable manufacturing process.

Impact on food processing safety

Food processing safety is profoundly affected by microwave drying. It reduces the risk of foodborne illnesses by effectively killing off all pathogens and spoilage microorganisms. In many cases, it provides a more uniform and thorough sterilization consistent with the conventional approaches. Moreover, this technique avoids extensive reliance on additives such as chemical preservatives, meeting consumers’ demand for clean labels and natural products. Equally important, microwave drying operates at lower temperatures to preserve food’s nutritional quality so that its safety improvements do not compromise the quality of nutrition. As a whole, microwave drying in food processing improves the safety and quality of foodstuffs to align with strict regulations and industry standards on food safety.

Reducing operational costs with microwave equipment

There is a considerable reduction in operational costs attributed to microwave equipment, which makes the drying process more efficient by using less energy and lower temperature. Microwave systems are said to be designed to concentrate on the moisture content of a product rather than using traditional methods that tend to waste energy and take longer for the products to dry, according to analysts of this industry. Consequently, the system reduces electric bill payments and minimizes carbon footprints. Furthermore, quick heating and uniform energy distribution leave no need for multiple types of machinery, reducing maintenance expenses and labor charges. This will help improve productivity and ultimately increase profits while promoting sustainable production methods through microwaves.

Challenges in implementing microwave sterilization technology

There are difficulties in executing microwave sterilization technology. One major obstacle to be overcome is the cost of investment because microwave equipment could be more costly than conventional ones. Moreover, companies must tackle technical intricacies in adjusting the microwave process for various kinds of products so that they can be heated evenly without cold spots. Furthermore, there may also be regulatory impediments as industry standards and food safety regulations develop to accommodate this newer technology. Besides, workers must be taught how to operate and maintain microwave systems effectively, which may necessitate extra resources and time. However, the long-term advantages of microwave sterilization typically surpass the initial barriers encountered during its adoption process.

Technical considerations for industrial microwave drying

Several technical considerations must be made when implementing industrial microwave drying to guarantee perfect performance and quality of the product. To begin with, it is essential to determine the dielectric properties of the material since different materials have different rates at which they absorb microwave energy, which affects drying efficiency. These properties can also guide one in selecting the correct power levels and frequency. Another factor to consider is how the microwaves are applied to the product, whether there will be hot spots, and whether uniformity can be achieved. As such, mode stirrers may be required, or more than one microwaving source may need to be installed.

Further, moisture content and particle size significantly affect the drying kinetics of materials. Proper pretreatment and reduction in size can improve drying time and energy consumption, respectively. Additionally, real-time monitoring entails integrating sensors and control systems that aid in adjusting parameters, keeping process stability, and replenishing product quality intact. So, safety measures against microwave radiation and thermal hazards should exist to ensure a safe working environment.

Overcoming limitations of microwave heating

Several strategic approaches can be used to overcome the shortfalls of microwave heating. Adjusting power levels and heating cycles can help reduce uneven heating and prevent thermal runaway. The use of advanced microwave oven designs with improved power distribution technologies, such as mode stirrers or rotating turntables, is helpful in achieving uniform temperature profiles. Secondly, the overall efficiency of processes and the quality of products can be improved by hybrid heating systems that combine microwaves with conventional heating methods. These systems utilize the quick rates of heat application of microwaves while using traditional methods to ensure uniformity and penetration depth. Thirdly, real-time adjustments can be made due to precise control and monitoring technologies such as infrared cameras and embedded sensors, essential for maintaining consistent heating. Furthermore, adjusting materials to specific microwave frequencies may increase absorption and process efficiency. Lastly, correct maintenance practices should be followed to prevent potential dangers, and safety procedures should be adhered to to render it more reliable and flexible when dealing with such perils during microwave heating.

Maintenance and care of sterilization equipment

Efficiency, reliability, and safety are essential in ensuring that sterilization equipment is adequately maintained and taken care of. This means that cleaning and inspection are needed frequently for autoclaves, microwave-based systems, and other sterilizers to avoid being contaminated. Therefore, it’s essential to adhere to the manufacturer’s procedures for routine maintenance, which entails descaling, lubricating moving parts, and replacing worn-out seals and gaskets, among others. Calibration checks should be performed periodically to verify that temperature and pressure settings are accurate. Moreover, all sensors and control systems must be tested to ensure that they give exact feedback or monitor the situation accurately. Detailed maintenance records help track equipment status and support timely service actions. In conclusion, safe operation requires observance of safety protocols, such as the use of protective clothing while handling harmful waste materials, amongst other rules.

Frequently Asked Questions (FAQs)

Q: What is microwave sterilization equipment, and how does it work?

A: Microwave sterilization equipment uses electromagnetic waves to generate heat and sterilize items. The process involves uniform heating, which helps to reduce or eliminate microorganisms in food products. This method is efficient and effectively reduces the moisture content of the items.

Q: How does microwave technology differ from traditional sterilization methods?

A: Unlike traditional sterilization methods that rely on hot air or steam, microwave technology uses electromagnetic waves to heat and sterilize products. The effect of microwaves is rapid and offers uniform heating, which helps to preserve the quality and nutrients in food products. It is also an energy-saving alternative.

Q: Can microwave sterilization equipment be used for food drying?

A: Yes, microwave sterilization equipment can be used for food drying. This is commonly seen in a microwave or industrial microwave dryer, which not only sterilizes but also removes moisture from food products. This method is ideal for drying vegetables, meat, and other food items.

Q: What types of food can be processed using commercial microwave drying equipment?

A: Commercial microwave drying equipment can process various foods, including vegetables, meat products, and other items that need drying and sterilization. This equipment is especially beneficial in the food industry for ensuring food safety and extending shelf life.

Q: What are the benefits of using an industrial microwave oven for sterilization and drying?

A: An industrial microwave oven offers several benefits, including faster processing times, uniform heating, and energy efficiency. It effectively reduces microorganism count in food items and can handle large quantities, making it ideal for commercial use.

Q: How does the action of the microwave improve the food sterilizing process?

A: The action of the microwave improves the food sterilizing process by providing rapid and uniform heating, which ensures all parts of the product are equally sterilized. This decreases the risk of under-sterilization and helps maintain the quality of food products.

Q: Is microwave sterilization equipment suitable for drying and sterilizing meat products?

A: Yes, microwave sterilization equipment is suitable for drying and sterilizing meat products. It ensures uniform drying and effective elimination of microorganisms, providing safer and longer-lasting meat products.

Q: Can I use microwave sterilization technology for vegetable drying?

A: Absolutely, microwave sterilization technology is effective for vegetable drying. The microwave drying equipment ensures rapid moisture removal while maintaining the nutritional quality of the vegetables.

Q: What should I consider when choosing a microwave sterilization dryer machine?

A: When choosing a microwave sterilization dryer machine, consider factors such as the type of food products you will be processing, the machine’s capacity, energy efficiency, and the effectiveness of the microwave power. It’s also essential to evaluate features like uniform heating and ease of operation. If you need more information, feel free to contact us.

Q: How does microwave technology help in food sterilizer applications?

A: Microwave technology helps in food sterilizer applications by using electromagnetic waves to kill harmful microorganisms efficiently. This technology ensures that the sterilization is uniform and quick and preserves the quality and freshness of the food products.