Industries’ dry moisture has been revolutionized by microwave drying systems that are faster, more efficient, and more uniform than the traditional methods in which they function. They have been designed to reduce drying time and energy consumption through advanced microwave heating, making them an increasingly appealing alternative for various sectors, including food processing, pharmaceuticals, and materials engineering. This article will uncover the technical jargon surrounding microwave drying, or rather, it will be a one-stop shop for businesses seeking direction about what they need to know for this process towards optimizing its use in their businesses. An understanding of how microwaves heat things and what influences their efficiency can better inform companies’ processes, improving product quality and enhancing operations cost-effectiveness.

What is a Microwave Drying System?

A microwave drying system uses microwave energy to remove moisture from diverse items. It is through the production of electromagnetic waves, which on reaching a material cause the polar molecules-water, for instance- to vibrate. Such oscillation results in dielectric heating that vaporizes water content as it gets heated up. In addition, rapid and uniform removal of moisture is involved in this process coupled with low thermal gradients and high energy efficiency. As such, it is highly useful in applications that need specific conditions during drying and quality control such as food processing, pharmaceuticals companies and materials engineering sectors.

How does a microwave drying system work?

The mechanism behind microwave drying system lies in generating microwaves that are usually between 915 MHz to 2.45 GHz absorbed by polar molecules like water present within the material. Thus absorbed energy makes water particles oscillate at a faster rate causing heat generation through dielectric heating process. Consequently, this heats eventually dries up the material.

Key technical parameters include:

- Frequency: Between 915MHz-2450MHz

- Power Density: About 10-100 W/kg of the material (if desired drying speed and ease of evaporation are needed).

- Temperature Control: Maintaining target temperature range between 30°C – 150°C by precise thermal monitoring.

- Moisture Content: The initial and final moisture content variance should not exceed 2-10%.

The efficiency of the drying process depends on many factors, including, but not limited to, the dielectric properties exhibited by the materials under study, their initial humidity levels, and the power density applied for its actualization purposes. By calibrating these aspects, it becomes possible to achieve speedy and uniform water loss, thus optimizing dehydration across various industrial applications.

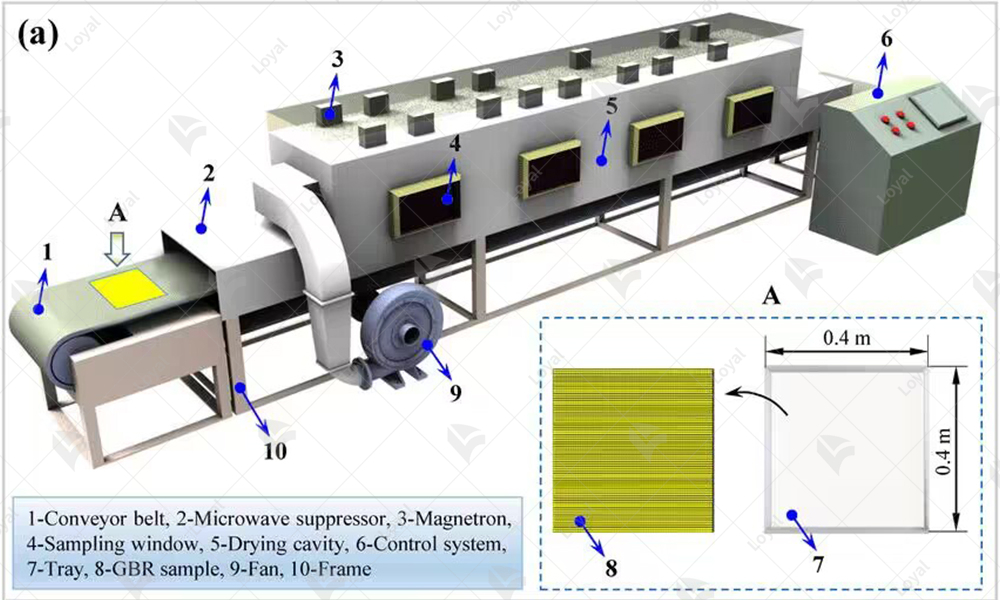

Components of a microwave drying system

There are several major components of a complete microwave drying system whose task is to cooperate so as to achieve maximum moisture removal efficiency. These consist mainly but not solely;

- Microwave Generator: It produces the required microwave energy from 915 MHz to 2.45 GHz.

- Waveguide: This guides the microwave energy generated by the generator into the drying chamber while ensuring that there is no power wastage and minimizing losses.

- Drying Chamber: This prevents material that is supposed to be dried from being affected uniformly by initial and, lastly, intermediate exposure to microwaves. As such, it can handle different kinds of materials, such as granular substances or even liquids.

- Conveyor System: Ensures uniform exposure of materials as they pass through at a constant speed varied by various settings.

- Temperature Sensors: Measure temperature changes taking place within drying chambers, monitoring them to regulate temperatures toward optimal drying conditions without overheating.

- Moisture Sensors: Keep track moisture levels on a real time basis; thus making it possible to have a precise control system enabling attainment of specific dryness contents as per requirements.

- Control Unit: This unit ensures that parameters such as frequency, power density, conveyor speed, or temperatures are set accordingly so that different raw materials can be processed efficiently and versatilely.

All these components ensure that their system runs with utmost efficiency, yielding maximum results that are often tailored to industrial standards.

Advantages of employing microwave drying systems.

Microwave drying systems are more advantageous than traditional drying methods because of their heating mechanism and energy transfer. One major advantage is a reduced drying time. Microwaves can heat the material internally, so that it dries quicker by hastening moisture evaporation. This means that this process takes only half to 70% of the conventional method’s length. On top of that, microwave drying often demands between 2-4 kWh per kilo gram of evaporated water because the material absorbs energy directly.

Moreover, as opposed to convectional procedures, microwaving guarantees even liquid extraction. It prevents uneven distribution throughout the product and hot spots or degradation caused by this inhomogeneity in moisture content levels. This homogeneity preserves these materials’ structure and nutrients against heat damage. Microwaves are able to control dryness with precision thanks to modern sensors and controls. The parameters like microwave power density (usually 1-10 W/cm²), conveyor speed or target humidity level can be fine-tuned to match different materials or specific industrial purposes, making them highly versatile in various applications. In short, better quality consistency across products, shorter operation times and saving on input costs represent valid reasons for using microwaves in industrial processes today

How does Microwave Heating Compare to Traditional Drying Methods?

This makes microwave heating different from traditional drying techniques because of several factors. Firstly, it dries faster as it can generate heat within the material itself. Other methods, such as air drying or oven drying, rely on surface heating, which may take longer time because heat is gradually absorbed into the inner sections. Secondly, microwave heating is more effective in terms of energy efficiency since it converts electric energy directly to thermal energy within the material without going through other steps used by regular methods; hence, reduction in energy consumption rates in the system. As a result, power usage declines significantly. Finally, yet importantly, microwave drying ensures that there is uniform moisture removal across the whole material, reducing problems such as surface over-drying, hotspots, and degradation that are common with conventional drying regimes where these materials are concerned. In fact this becomes very important especially when dealing with delicate substances that would be affected by heat damage thus ensuring the quality and consistency of the final product.

Advantages of Microwave Heating Compared to Traditional Techniques

Microwave heating has several benefits over traditional drying methods:

- Speed and Efficiency: Drying with microwaves takes relatively less time due to the internal production of heat compared to conventional methods, whereby heat flows gradually from surface to inside, leading to the extended period for its completion. A research has shown that using microwaves increases speed up to 50-90% versus traditional ones.

- Energy Consumption: Microwaves emit their own waves without any loss of electricity because they change electrical input into thermal output which does not require them to use any other medium like old practices do. This has resulted into up to 40% less power consumption while utilizing microwave dryers than those designed according to standard technologies. It also provides optimal value for different performances by varying power densities between 1-10 W/cm².

- Uniform Moisture Removal: The evenness in moisture elimination during a Microwave Drying process prevents issues such as paling edges, hot spots or breakdowns so rampant with traditional drying schemes. It is a big part of quality control for heat sensitive materials which require set drying parameters. The uniform application of microwaves guarantees that the entire volume of material undergoes the effective microwave drying process maintaining its structural integrity and preserving the quality of final product.

Energy Efficiency in Microwave Drying

The reason why microwave drying is considered energy efficient is that it converts electrical energy directly into heat within the material to be dried, unlike conventional methods, which involve a series of processes, making them lose more energy. Report from top industry sources has validated that power density can be controlled with 1-10 W/cm² being the ideal range, thereby giving a platform for managing energy accurately while minimizing wastage. Furthermore, microwaves heat rapidly such that only the material itself without surrounding air gets heated, thereby reducing the electricity used. This targeted approach reduces energy consumption and lowers operating expenses, making microwave drying increasingly attractive for numerous industrial operations.

However exactly how long have these taken and what effect did they have on product quality?

Microwave drying has higher efficiencies in production quality and shorter processing times compared to traditional techniques. Shorter durations are a consequence of microwaves reaching inside materials volumetrically through internal heating mechanism where they penetrate it and warm up. This results in faster moisture extraction rate which often shortens duration by upto 50-75% depending on material type or particular conditions under which samples were dried respectively.

Maintaining a controlled power density within the range of 1-10 W/cm² is critical in achieving optimal results as per top research sources. In order to ensure consistent drying, precise control over this parameter is necessary so as to prevent thermal damage and preserve such essential attributes as texture, color and nutrient content. Further technical metrics emphasize that monitoring drying rate (g/min), moisture content (%), and product temperature (°C) are important; these metrics enable actions for fine tuning the drying process.

For instance, some studies have indicated that for heat-sensitive materials like pharmaceuticals, a drying rate of 0.5-1.5 g/min with final moisture content below 5% is desirable for maintaining the product’s efficacy and stability. Moreover, it is possible to prevent degradation by keeping the product temperature within 40-60°C so as to produce high-quality outputs only. Thus, The benefits show how microwave drying can help streamline operations while ensuring superior quality products and efficiency.

Factors Affecting the Drying Process in Microwave Systems

Drying process is critically influenced by several factors in microwave systems which include; material dielectric properties, sample geometry and initial moisture content. Dielectric properties are the defining characteristics of how a material interacts with electromagnetic field which is crucial for heating uniformity and efficiency. Materials with high dielectric constants absorb microwaves more effectively leading to faster drying rates. Sample geometries such as thickness, shape and orientation influence the uniform distribution of microwaves. The presence of uniform sample shapes ensures that there is even heat distribution as well as moisture removal throughout a particular material while other shapes may lead to uneven drying on different parts. Finally, the initial moisture plays a significant role; materials with greater initial moisture will be heated faster at first due to more water molecules present that can efficiently absorb microwave energy. This kind of control must take place properly so that there is efficient and homogeneous drying in microwave systems.

Influence on drying process by moisture content

The influence of moisture content on drying in the microwave system is huge. Such materials tend to heat up faster initially since water molecules absorb microwave energy more effectively, resulting in rapidly increasing temperature. As it proceeds towards its end, drying reduces the rate at which temperature rises, forcing power adjustment on microwaves to maintain an effective process. A good number of sources indicate that for most applications, optimal moisture content levels required for optimum drying should generally fall below 5% so as to guarantee product stability and quality improvement.

- Initial Moisture Content: Higher initial moisture levels (>20%) can accelerate drying rates due to the efficient absorption of microwaves by water molecules.

- Microwave Power Levels: Usually, one prefers power settings lying between 200-800 W whereby they adjust them depending upon initiatory moistures as well as desired final humidities.

- Temperature Control: Effective removal of moisture should be undertaken without degrading products where temperatures have to remain within 40-60°C.

Managing hot spots in microwave dryers

Hot spots are a common problem in microwave dryers, caused by uneven distribution of microwaves that can result to localized overheating and damage the product. This challenge can be mitigated by employing various technical strategies. The use of mode stirrers within the microwave cavity helps to prevent hotspots due to their random shifting of paths taken by waves thereby making it possible for better microwave distribution throughout the chamber. Furthermore, rotating the product within the oven dryer will even out its exposure to the microwave energy. A feedback control loop is also included in modern microwave systems, which monitors temperature distribution inside them, and then regulates the output power accordingly, reducing chances of hot spot formation. In addition to this, one cannot help but mention about how drying chambers are designed as well as materials used together with locations where microwaves sources are situated since they play an essential role in minimizing these inconsistencies through providing much more uniform field arrangements. These methods will significantly improve drying homogeneity while enhancing product quality.

Optimizing drying time and efficiency in the dryer

Optimizing drying time and dryer efficiency requires an integrated approach that accounts for operational parameters as well as the properties of the material to be dried. A critical first step is to accurately determine the drying curve of each product, which shows how quickly moisture is being removed over a given period. This can be done through experimental trials and using mathematical models to predict drying behavior. Some of the most important parameters to regulate include drying temperature, air velocity, relative humidity, and specific energy input. For example, although there are safe limits for increasing the drying temperature which can reduce down significantly the drying time; however, it should be balanced with chances of thermal degradation.

Advanced drying systems often use real-time monitoring and adaptive control strategies to increase efficiency. In this regard, sensors track moisture levels and temperatures without interruption while algorithms adjust the dryers’ conditions on the fly. By doing so, these gadgets ensure that they use energy effectively, making them work at their best while maintaining high product quality.

Moreover, improved energy savings in dryers can also come from recovering and reusing waste heat from exhaust air. Waste heat recovery equipment like heat exchangers trap thermal energy contained in smoke and return it back into production processes, thereby reducing overall energy consumption.

Predictive maintenance can also improve dryer efficiency. Regularly checking essential parts, coupled with maintenance based on predictive analytics, will minimize downtime and keep a dryer efficient throughout its lifespan.

In conclusion optimizing dryer efficiency and decrease drying times needs accurate regulation of numerous variables involved through advance control systems with monitoring capacities this includes saving energy techniques as well as predicting future failure situations which will increase performance output

How Can Microwave Systems Enhance Food Drying Applications?

Food drying applications greatly improved when microwave drying systems were introduced; they have faster drying times and offer better energy efficiency. They differ from conventional drying methods that depend on surface heating by penetrating the foodstuff causing water molecules to vibrate internally generating heat. This internal heating shortens the time of drying and minimizes heat damage to the product, thus maintaining nutritional value and sensory properties. Also, these systems result into uniform drying which minimizes uneven moisture content hence reduces chances for spoilage. Besides, with real-time monitoring as well as control technologies integrated in them microwave drying systems can dynamically adjust power levels and other settings thereby making it since effective for different types of foodstuffs.

Benefits of Microwave Drying for Fruits and Vegetables

Microwave drying has multiple benefits on fruits and vegetables in terms of efficiency and quality of products. Firstly, it cuts down the time consumed during this process compared to other conventional ways of doing so. For example, some studies indicate that under certain conditions microwave heating can reduce the duration from hours to minutes; thus preserving the integrity and nutrition of temperature-sensitive fruits or vegetables. The energy consumption rating is also quite low in comparison to the conventional hot air dryers that are power hungry.

As a matter of technical parameters, microwaves usually operate at around 2,450 MHz using dielectric heating which targets water molecules within the food matrix. In this way moisture removal is uniform throughout resulting in more consistent end products. Empirical data demonstrate that diffusivity values for microwave-dried fruits and vegetables are much higher compared to their counterparts that undergo thermal processing implying efficient as well as uniformity while removing moisture.

Moreover, numerous health beneficial compounds found in fruits and vegetable become resistant against thermal degradation through microwave-aided procedure when compared with convective drying methods. For instance, the dried products that are prepared by microwave contain higher levels of antioxidants and preserve better color compared to those made through other methods. This makes the system suitable for creating processed fruits as well as vegetables that maintain their quality attributes such as taste and nutritional composition.

Improving Food Products with Microwave Treatment

The use of electromagnetic waves on food products comes in handy when dealing with microwave treatment because they fall in a range of about 300 MHz to 300 GHz. The specific frequency used for microwaves is often approximately at 2,450 MHz which promotes dielectric heating by making polar molecules within food move thereby giving out heat in form of electrical energy. This efficient and rapid method greatly enhances the drying process; consequently, it uses less energy than conventional approaches since processing times are shorter.

Technical Parameters:

- Frequency: Generally operates at 2,450 MHz to optimize dielectric heating.

- Power Levels: Adjustable depending on the specific food product, ranging from low wattage for delicate items to higher wattage for more robust materials.

- Temperature Control: Typically features precise control to maintain lower temperatures and minimize thermal degradation.

Benefits:

- Energy Efficiency: Microwave drying typically requires less overall energy due to the reduced processing time.

- Uniform Drying: Achieved through targeted dielectric heating, ensuring consistent moisture removal across the food matrix.

- Retention of Nutrients: Lower temperatures and quicker drying preserve nutritional value, antioxidants, and vitamins.

- Improved Quality: Better color retention and enhanced sensory characteristics due to minimized exposure to high temperatures.

Microwave processing has been shown by several empirical studies and reviews from leading sources to significantly improve the drying process, while preserving its inherent nutritional and sensory attributes thus making it a better choice than conventional thermal procedures.

Moisture Content in Food Drying Addressed With Microwaves

To effectively address moisture content when drying food with microwaves, it is necessary to know what the specific moisture content of that particular product is. Thereby, microwaves enter into the foodstuff, causing oscillation of water molecules resulting in internal heat that compels moisture to be driven outwards for evaporation. The microwave heating mechanism inside makes it different from conventional methods and leads to more even reduction of moisture content. Power level control and processing time have been proven to be significant points towards optimum decrease in humidity without affecting quality attributes of the final product. Moisture levels should therefore be continuously monitored hence microwave settings adjusted accordingly; this way operators will end up with an efficient practice, which is exact on moistures while eventually improving overall drying process.

Can Microwave Heating Improve Industrial Drying of Non-Food Products?

Microwave heating application in the industrial drying of non-food products has indicated promise in various studies. Compared to traditional drying techniques, microwave drying is characterized by shorter processing time and higher energy efficiency. The technique uniformly heats the material as a result of volumetric heating which is useful especially on thick or complex structures. Besides, the technique can be used to dry ceramics, textiles and pharmaceuticals while still maintain their physical and chemical properties such as reducing moisture content through evaporation of water. This calls for the integration of microwave heating into industrial drying processes so as to enhance significant improvements in drying rate, energy consumption and product quality.

Enhancing Drying And Adhesive Properties Through Microwave Technology

Microwave technology enhances considerably drying and adhesive properties across different materials. Recent studies have shown that microwave heating could reduce by half the amount of time it takes to dry something due to volumetric heating effect which raises equally temperature within materials. In order to avoid thermal degradation and ensure better adhesion in composite materials this method lowers its possibility. The crucial technical parameters include power density (which usually varies between 0.1-5 W/cm2), frequency (usually at 2.45 GHz for industrial applications) and process time which must be well regulated for proper optimization of both drying and adhesive conditions. Monitoring temperature is also important; cures are typically run from about 120°C to 240°C without jeopardizing structural integrity of the bond with an adhesive . Thus not only does microwave technology speed up production but also improves the quality and durability of output.

Applications Of Microwave Power In Color Drying And Adhesive Setting

Due to its ability in color dying and adhesive setting, microwave power has various uses like textiles dyeing industry, paper manufacturing industry, ceramics among others , as well as automotive manufacturing sector. In textiles, dyed fabrics can be dried faster using microwaves thereby promoting uniformity in colors while at the same time saving energy during this process. In this case, optimal drying power density of 0.5-2 W/cm² and frequency of 2.45 GHz is ideal as the colors won’t fade as well as the fabric will not be destroyed during drying. For the paper sector, microwave aids in fast drying of printed inks and coatings that increase production efficiency .For proper drying without affecting print quality, there should be a power density of 1-3 W/cm² or temperature range from110 to160°C.

In ceramics field, microwave power is used in drying and setting pigments and glazes for uniform application with less time needed. These include 1-4 W/cm²power density as well as processing temperature that ranges between150°C –200°C so as to avoid development of defects such as warping and cracking among many others. Furthermore, adhesive bonding is done through microwave technology in automotive industries especially when it comes to assembling composites and vehicle interiors. The best setting involves having power densities that range from 0.5-5W/cm²; temperatures should be maintained between 120°C –240°C which would ensure quick curing leaving behind durable bonds . Therefore microwave power improves process efficiencies while producing high quality end products in various applications.

Choosing the Right Microwave Drying System for Your Needs

Selecting the appropriate microwave drying system requires a consideration of several key factors. To begin with, examine material characteristics together with specific purposes such as moisture content, thermal stability and end quality of the product. Evaluate power density and frequency of the system to ensure compatibility with these requirements also considering energy efficiency and environmental impacts that it may have. Moreover, consider if the system can be expanded or reconfigured in case of any growth or changing demands related to production scale. Finally, assess overall cost ownership associated with installation, maintenance and daily operational expenses to ensure that an all-inclusive long-term approach matches your technical constraints as well as budget.

Key considerations for selecting a microwave drying system

- Material Compatibility: The most important thing is understanding the properties of the materials being processed. The moisture content determines the appropriate power density and frequency required by the system for the desired final product quality and thermal stability. For example, depending on their dielectric properties, these might be powered by 0.5-5 W/cm² at frequencies of 915 MHz or 2450 MHz.

- Energy Efficiency and Environmental Impact: Choose equipment that maximizes energy consumption minimizes waste production and emissions. Energy-efficient microwaves are designed to reduce operating costs and promote sustainable development within organizations offering them therefore improving their profit margin . More information on this regards can be obtained from analyzing kilowatt hours (kwh) per dried unit produced tells more about how efficient a machine is in terms of energy usage.

- Scalability and Modularity: Consider whether it could easily grow or shrink along side production-volume variations? A modular design flexibility feature allows future expansion should there be need for more capacity later on . This means that such investments remain relevant even when circumstances change.

Maintenance and operational tips for microwave dryers

Microwave dryer maintenance should be done regularly to ensure consistent operations and long life. To start with, check and clean magnetrons, waveguides, and drying chambers regularly to avoid any accumulation of deposits that can lower efficiency. Secondly, provide for good ventilation and air circulation both inside and outside the system to prevent overheating and any other resulting damages on components. Besides this, frequent checks of temperature control and power setting calibration are essential to ensure accurate drying parameter regulation. Lastly, scheduled electrical connection tests, including safety and interlocks, would help reduce unplanned downtimes, thus enhancing overall system safety. Adhering to such maintenance practices will allow you optimize your microwave drying systems performance while prolonging its lifespan.

Frequently Asked Questions (FAQs)

Q: What are industrial microwave drying systems?

A: Industrial microwave drying systems use microwave energy to efficiently dry and heat various materials. These systems are known for their ability to quickly and uniformly dry products compared to traditional methods like drying rooms and convection ovens.

Q: How does microwave heating and drying work?

A: Microwave heating and drying work by generating electromagnetic waves that penetrate materials. The microwave energy causes water molecules to vibrate, producing heat from the inside out, which makes drying with microwaves substantially faster and more uniform.

Q: What are the main applications of industrial microwave systems in industrial processes?

A: Industrial microwave systems are used in various applications, including food processing, pharmaceutical manufacturing, ceramic and rubber processing, drying out building materials, and adhesive setting properties of microwave techniques. Their efficiency in drying and heating makes them suitable for many industrial processes.

Q: Can microwave drying systems improve efficiency compared to traditional drying methods?

A: Yes, microwave drying systems can significantly improve efficiency compared to traditional methods like drying rooms and convection ovens. Microwave drying is quicker, more uniform, and provides energy savings, making it a superior option for many industries.

Q: What is the role of vacuum drying in industrial microwave processing?

A: Vacuum drying in industrial microwave processing helps preserve the quality of heat-sensitive materials by lowering the boiling point of water. This technique enables drying at lower temperatures, which protects the product’s structure and quality.

Q: Are industrial microwave systems suitable for adhesive drying?

A: Yes, industrial microwave systems are excellent for drying adhesives. The adhesive setting properties of microwave technology ensure rapid and uniform drying, which is crucial for maintaining the adhesive’s strength and durability.

Q: What are the advantages of using microwave energy in industrial processes?

A: Microwave energy is an attractive option in industrial processes due to its high efficiency, speed, energy savings, and uniform heating. It enhances the quality of the final product, reduces drying time, and minimizes energy consumption.

Q: How do ferrite microwave technologies contribute to industrial microwave systems?

A: Ferrite microwave technologies enhance industrial microwave systems by providing efficient and reliable microwave generation and transmission. This ensures consistent performance of the microwave heating and drying system.

Q: What are the benefits of using a complete microwave drying system?

A: A complete microwave drying system offers a turnkey solution for industrial drying needs. It integrates all components required for efficient microwave heating and drying, leading to streamlined operations, improved product quality, and reduced operational costs.

Q: Is microwave processing safe for industrial applications?

A: Yes, microwave processing is safe for industrial applications when properly designed and operated. Industrial microwave systems are engineered with safety features to prevent hazards and ensure safe and efficient operations across various industrial applications.