Microwave drying systems represent a significant advancement in food processing, offering numerous advantages that enhance efficiency and product quality. These systems employ electromagnetic waves to rapidly heat and evaporate moisture from food products, accelerating the drying process compared to conventional methods. This technique reduces drying time and ensures uniform moisture removal, which is critical for maintaining food safety and extending shelf life. Moreover, microwave drying systems are highly energy-efficient and can be precisely controlled to preserve food items’ nutritional and sensory attributes. This article will delve into the technical aspects, operational benefits, and practical applications of microwave drying systems, providing a comprehensive overview for industry professionals and researchers interested in cutting-edge food processing technologies.

What is Microwave Drying?

The process of microwave drying is the application of microwave energy to evaporate moisture from food materials. This technique uses electromagnetic waves created in the microwave spectrum, typically at 2.45 GHz. The waves go inside the food materials and interact with water molecules, resulting in their oscillation, thus releasing internal heat as a result. It helps in faster and efficient moisture evaporation, leading to fast drying time. Microwave drying however, unlike conventional methods of drying which involve heating on the surface followed by diffusion of moisture ensures even removal of moisture across the product. This method reduces drying times and energy consumptions while maintaining food’s nutritional and sensory properties.

Understanding Microwave Drying Technology

Microwave drying technology works depending on how much microwaves interact with water molecules in food products. The key factors controlling this technology include frequency, power level and drying time.

Frequency: Food microwave drying is normally done at around 2.45 GHz because it allows for good penetration depth and maximum absorption by water molecule. At this frequency, it becomes possible to evaporate water without causing major modifications to the structure of foodstuff.

Power Level: A microwave system’s power level determines how fast it will dry an item under treatment. Higher power levels lead to higher oscillations of water molecules, hence faster dehydration. However, high levels may result in non-uniform or overheated products; therefore, these should be tailored based on the type of food material and targeted drying attributes.

Drying Time: The duration needed for drying changes according to initial water content, thickness as well as composition that a given product exhibits among many other variables which are control parameters responsible for this action (Singh & Heldman 2009). Moreover, compared to conventional methods, microwave creates shorter cycle time as they usually attain desired final moistures within minutes only and this contribute towards enhanced preservation qualities related with nourishment facts.

Thus, control over these factors allows customization in terms of operational parameters of microwave drying systems to guarantee uniform and effective product drying. This is critical for food safety, shelf life extension, and preserving the quality inherent in the products.

How Does a Microwave Drying System Work?

Microwave drying systems work by emitting electromagnetic waves at a frequency of 2.45 GHz which penetrate through food materials. These microwaves interact with water molecules in the food causing their fast oscillation. Such rapid vibrations create kinetic energy that heats up the water thereby heating it up effectively. Water changes into vapor after attaining boiling point hence escaping from food matrix thus bringing about dryness.

Three Key Technical Parameters

- Frequency (2.45 GHz): This is the most common frequency used to effectively remove moisture without affecting the overall structure of a given food material since its maximum absorption occurs at this level.

- Power Level: The use of appropriate power levels is important because increased power enables faster evaporation; however, there should be no uneven drying or overheating due to excessive energy input. Power levels depend on the type of foods being processed, such as 500W and 1500W, depending on moisture content.

- Drying Time: The exact time required for microwave exposure depends on different factors including initial moisture content, density, thickness and other control parameters responsible for this process (Singh & Heldman 2009). Drying durations vary between five and thirty minutes allowing preservation of organoleptic properties as well as nutritional values

Microwave drying systems can dry food quickly, uniformly, and energy-efficiently while maintaining its quality through careful calibration of these parameters.

Advantages of Microwave Drying in Food Processing

Microwave drying has a number of benefits over conventional methods used to dry food. This is mainly because it reduces the drying time by interacting with water molecules directly which leads to rapid extraction of moisture. The microwave’s high-frequency (2.45 GHz) makes sure that water molecules pick up just the right amount of this energy. Also, microwave drying improves energy efficiency because only the heat required for evaporation is generated by food; as opposed to old techniques where all environmental surroundings are heated. For instance, this method helps reduce total power consumption.

Moreover, microwave drying aids in conserving the nutritional and sensory attributes of food items. By maintaining power levels between 500W-1500W and ensuring a typical drying period varying from 5 minutes to – 30minutes, microwaves prevent overheating and unevenness in desiccation, thereby retaining nutritive value and texture. In addition, it provides uniform dehydration which minimizes microbial proliferation and ensures constant product quality. In addition to being a super fast means of desiccation, microwave systems offer shorter periods due to accurate control making them suitable for preservation purposes thus prolonging the life span for dehydrated commodities within the food industry.

How is Industrial Microwave Drying Different from Conventional Methods?

Industrial microwave drying is different from conventional methods in several ways. To begin, the dryers use electromagnetic waves which generate heat inside food that is much faster and more uniform than conventional hot air or freeze-drying processes which heavily depend on surface drying and transfer of heat. This has led to significant time savings and increased productivity. Secondly, microwave systems allow the drying conditions to be controlled effectively to maintain optimum temperatures while minimizing risks of over-drying or thermal degradation thus preserving nutritional and sensory quality of foods. On the other hand, traditional approaches often consume more energy and take longer during processing due to indirect heating mechanisms. Lastly, it should be noted that these systems can be easily integrated with automated production lines thereby making them scalable unlike conventional ones of this nature hence increasing industrial efficiency and product uniformity.

A Comparison between Microwave Drying and Hot Air Drying

Microwave drying fundamentally differs from hot air drying with regard to their operational mechanism as well as impacts on drying process .Microwave drying does not require contact between its heating medium electromagnetic waves with foodstuff before heating resulting into a greater rate of moisture removal within the shorter period…..Hot air dryers rely on convective heat transfer to remove internal moisture (Abdulmumin et al., 2015). Consequently, this method dries from outside inwardly leading to long periods of operation accompanied by deteriorated quality.

From a technical standpoint, high drying rates up to 2.24 kg/h have been achieved using microwave dryers at energy efficiencies ranging between 30-50% due to direct interaction of water molecules with microwaves compared to hot air dryers with lower energy efficiencies ranging between 15-25% which sometimes take a longer time to attain similar levels of moisture contents.

Another essential difference is temperature control; microwave systems are capable of maintaining optimal temperatures around 30-90°C that aid in preservation of nutritive components as well as sensory properties for foods whereas hot air drying typically involves higher temperatures above 100°C which can lead to thermal degradation or loss of nutrient value.

In terms of scalability and integration, microwave drying systems are advantageous due to their compatibility with automated processes, whereas hot air dryers often require batch processing and less flexible integration into continuous production lines. Therefore, in view of these technical aspects, microwave drying is better than hot air drying in terms of efficiency, quality preservation and industrial adaptability.

Benefits of Industrial Microwave Drying Systems

Several significant benefits accrue from the use of industrial microwave drying systems as compared to traditional methods. Firstly, they significantly reduce drying times due to their ability to heat water molecules within the material directly. This results in lowered thermally induced stresses and more even moisture gradients throughout thus improving product quality. For instance, during mircowave process, it can remove as much as 2.24 kg/h and have an energy efficiency ranging from 30-50% while in hot air dryers only operate at a paltry 15-25% efficiency that takes longer periods for the same moisture content removal.

Furthermore, using controlled temperature settings during microwave processing within the range of 30°C to 90°C helps preserve the nutritional and sensory qualities of food products unlike hot air which may exceed temperatures above 100°C resulting into possible thermal degradation or nutrient loss.

In addition, automated production lines can be highly compatible with industrial microwave drying systems to be fitted into the existing manufacturing flows. It is this adaptability that supports continuous production for improved efficiency and scalability. Besides, the use of energy by targeting water molecule translates to less wastage, hence making microwave drying a more sustainable way to save on costs and conserve the environment in terms of operation expenses.

Various Food Applications of Microwave Drying

Multiple food sectors have successfully implemented microwave drying technology. For instance, one notable application is drying fruits and vegetables. This process helps maintain color, texture, and nutrition content, which are lost in conventional drying methods. One example of this is an apple, which, through microwaves, has its moisture reduced to about 5-10%, and vitamins are kept at high levels compared to hot air heating.

Another application involves meat and fish dehydration. Microwaves significantly shorten processing time while increasing shelf life without compromising protein levels or general flavor profiles. As an illustration, moisture content in microwave-dried meat products goes below 10%, ensuring safety against microbiological hazards as well as maintaining quality standards.

Additionally, powdered foods such as milk powder or instant coffee benefit from microwave drying. Therefore, it provides rapidity and uniformity in removing moisture from powders, sustaining their quality and solubility requirements at all times. Concerning energy consumption in microwave drying, these products can go down to 1.5 kWh/kg, unlike higher figures noted during traditional drying methods.

It can therefore be observed from the food industry applications highlighted above that this technology not only enhances product quality and nutrient preservation but also increases productivity efficiency and encourages sustainability programs within organizations.”

Can Microwave Drying Handle High Moisture Foods?

Microwave drying is indeed capable of effectively handling high moisture foods. This technology makes water molecules vibrate through microwaves, leading to their rapid evaporation. This characteristic makes microwave drying particularly suitable for high-moisture foods such as fruits and vegetables, as it ensures fast and uniform drying, thereby maintaining the integrity and nutritional value of the product. Moreover, studies show that microwave drying is efficient for food with high initial moisture content because it decreases the time required to dry such products and improves the quality compared to traditional drying methods. Besides, microwave drying minimizes microbial contamination by a considerable margin, thereby providing an opportunity for increasing the shelf life of highly moist solid food.

Challenges with High Moisture Drying

One of the main challenges faced when using microwaves in the process of dehydrating water-rich foods concerns temperature control and power levels used during this operation. This can lead to hot spots on some parts resulting in thermal degradation or scorching hence negatively affecting its quality. Additionally, attaining uniformity throughout all the irregularly shaped items during the process can be difficult in order to ensure consistent removal of moisture from them. In addition, cost might also act as a limiting factor towards adoption by some manufacturers who might find it expensive compared to conventional drying methods. Furthermore, reaching a desired texture and appearance without over-drying or under-drying remains a technical challenge requiring exact calibration and monitoring.

Innovative Solutions for High Moisture Microwave Drying

One area with huge potential in respect to high-moisture microwave drying is hybrid drying systems use. Combining microwave energy with other technologies like hot air dryers, vacuum dryers, and infrared heaters can help avoid overheating specific spots that are referred to here as hotspots within products during the processing stage. For instance, vacuum microwave drying (VMD) runs under reduced pressure, therefore enhancing both efficiency and uniformity while preserving heat-sensitive product attributes intact. On top of that, the research has shown that this drying method contributes to improved finished product quality with respect to nutrients retention, color and texture.

Another significant innovation includes integrating advanced control systems using machine learning algorithms and sensors. These systems can dynamically adjust power levels and temperature in real time based on various kinds of wet products. For example, through infrared thermal imaging, the system can detect temperature variations across a product’s surface and, hence, apply appropriate actions to ensure a similar drying rate.

The development of sophisticated microwave applicators is also notable, enhancing the uniformity of energy distribution within the drying chamber. New designs in applicators aim to minimize the occurrence of hotspots by refining wave patterns or energy delivery. Moreover, such technical parameters as frequency, power density, and modulation strategies are adjusted accurately until the required effects have been achieved.

Additionally, integrating moisture and temperature sensors directly into the microwave dryer setup enables continuous monitoring and feedback control guaranteeing optimal drying conditions at all times during processing. These improvements not only improve efficiency but also significantly reduce energy consumption, making it less costly. Advanced microwave drying systems offer significant potential for the food industry, particularly in achieving high-quality drying of high moisture foods while maintaining nutrient content and extending shelf life.

High Moisture Food Drying: Case Studies

Case Study 1: Microwave Drying of Strawberries

A study by the Department of Food Engineering, University of Lleida revealed that microwave vacuum drying (MAVD) was efficient for strawberries. This method allowed faster drying as compared to hot-air drying; however, it still maintains color and bioactive compounds in fruits. The study indicated that not only did MAVD improve on the drying efficiency but also caused better texture as well as rehydration properties leading to a superior product overall.

Case Study 2: Microwave Drying of Mushrooms

In a Food and Bioproducts Processing journal study, nutritional retention and textural attributes of mushrooms subjected to microwave drying were examined. According to this research, microwave drying preserved higher levels of essential vitamins and minerals compared with traditional methods. It also showed that microwave dryings possessed more uniform texture and surface characteristics which are significant for consumer acceptance and shelf life; these improvements relied heavily on some sophisticated forms of microwave energy distribution.

Case Study 3: Microwave Drying of Banana Chips

A research investigation published in the Journal of Food Science and Technology considered the application of microwave drying in making banana chips. Chips made using this method had lower oil contents compared to those prepared through other methods therefore they are healthier while being crispier which is beneficial both for health benefits as well as consumer preference. The study highlighted how different power densities achieved at various levels can be used in practicing optimal moisture elimination rates with respect to texture development times. Such case studies underline the potential benefits of using microwaving technology when producing healthy snacks with appealing taste buds.

What Are the Key Components of a Microwave Drying System?

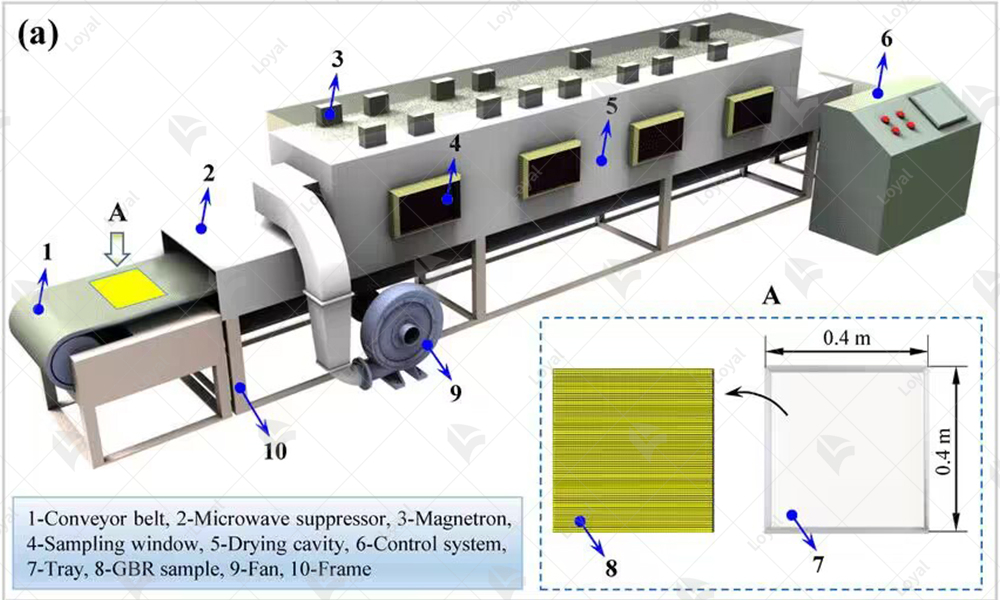

A microwave drying system has a number of crucial parts that guarantee efficient and effective drying. The key part is the magnetron, which is also referred to as the microwave generator. It supplies microwaves used for drying. They are transmitted via a waveguide into a drying chamber where materials for drying are placed. Inside this drying chamber, there is either a conveyor belt or rotating drum to provide equal exposure of all materials to microwaves. Besides, it contains a control unit that adjusts such parameters as microwave power, temperature, and time for optimum performance in the process of drying. Also important are ventilation and exhaust systems which are required to take away moisture and maintain specific environmental conditions within the dryer. Finally, monitoring devices and sensors have been put in place so as to keep track of such things like energy efficiency, moisture content, and temperature; therefore improving both product quality consistency and safety.

The Main Features of Microwave Heating Systems

Microwave heating systems have several main features that enable them operate efficiently in various applications. The main component is magnetron which is responsible for converting electric energy into high-frequency electromagnetic waves constituting microwave energy. These waves then pass through a waveguide into the heating chamber. Good performance by magnetrons ensures even generation of microwaves resulting in uniform heating throughout different food items being heated (Horne 1996). If anything it should be noted that it’s not just any other cavity but one with improved symmetry or cavities known as applicators (Brennan et al., 2003). This uniform distribution mainly happens because this cavity avoids hot spots while radiating microwave energy evenly throughout its volume (Duffield et al., 1995). On top of that, power supply unit that regulates input power for the magnetrons themselves complements an adjustable control system allowing setting up time-temperature-power levels accurately (Riley et al., 2010). Proper ventilation is required to draw off excess heat to ensure safe operation. Monitoring and controlling devices such as temperature sensors, can be used in advanced microwave systems to measure and control different parameters involved in the operation of these systems.

The Significance of Microwave Energy in Drying Procedures

Microwave energy plays a crucial role in drying processes by making it faster for materials to get rid of moisture using dielectric heating. Unlike conduction-convection drying methods, microwaves work at molecular levels where they directly heat water molecules inside the material. This results into much faster drying times with higher energy efficiency. Microwaves are applied at frequencies ranging from 300 MHz to 300 GHz during the process (Brennan et al., 2003). For instance, most industrial microwave drying systems operate at either 915 MHz or 2.45 GHz since these two frequencies provide optimal penetration depth coupled with heating uniformity.

Some important technical parameters that determine the effectiveness of microwave drying include the dielectric constant and loss factor that tell how well a material absorbs microwaves depending on its dielectric properties. In addition, appropriate control over power density has to be maintained not to expose this substance to high temperatures leading to degradation (Riley et al., 2010). The best power densities range from 0.5 up to 2 W/cm³ dependently on the kind of samples and their moistures (Brennan et al., 2003).

Another critical factor is temperature control. The internal temperature of the material should be monitored not to exceed the thermal degradation point. This involves using infrared sensors or fiber optic temperature sensors, which guarantee accuracy in control. Moisture content monitoring is carried out using capacitive or microwave moisture sensors for real time feedback that adjusts processing parameters.

Optimizing Microwave Power in Food Processing

There are several key factors on which optimization of microwave power in food processing depends. The first one is heating uniformity that ensures quality and safety consistency. Frequency and power settings can be adjusted to match the physical characteristics of food including its size, shape and dielectric properties so as to achieve this objective at an acceptable range of values. In addition, control over the moisture content in food is essential due to its significant role in microwave absorption rates. Real-time feedback based on advanced sensor technologies such as infrared and fiber optic sensors allows for precise control of temperature. On top of that, enhancement energy efficiency and product quality also depends upon the geometry and design of the microwave applicators. For process optimization, one can use computational modeling tools capable of simulating and predicting the thermal behavior of foods with potential for slight adjustment of microwave parameters.

According to reference materials from leading sources, integrating these techniques has been shown to result into significant advancements in processing efficiency, lower energy consumption levels as well as improved final product quality.

Is Microwave Drying Safe for Food Applications?

Microwave drying, when properly managed and monitored, is believed to be safe for food applications. This process applies electromagnetic waves that heat the food from inside causing moisture to evaporate efficiently. Compared to conventional drying methods, it has several advantages; fast drying rate as well as retention of nutritional and sensory qualities. However, safety concerns revolve around ensuring uniform heating so as to prevent microbial survival while avoiding high temperatures that degrade food quality. Sensor technology advances and control systems also play a role in mitigating these risks thus ensuring the process meets with safety and quality standards. Experts hold the view that if optimized microwave drying can be made to comply with industry safety regulations.

Ensuring Food Safety in Microwave Processing

Several key parameters and guidelines must be followed in order to ensure the safety of food during microwave processing. One such parameter is uniformity of heating which should not be compromised at all cost. The best thing about it is that according to most reputable online resources, even temperature distribution can be facilitated by using microwave stirrers or tumblers (1). Normally, a frequency of 2.45 GHz is recommended for food microwave processing due to its penetration depth suitable for different types of foods.

Another important factor is the maintenance of temperature; internal temperatures above or equal to 160°F (71°C) are recommended to avoid any possibility of microbial survival. Real-time feedback is increasingly being provided using newly developed sensors like fiber optic temperature sensors so as to ensure that the overall mass of food reaches the required temperatures evenly.

Moreover, careful design and positioning of the microwave applicators are crucial factors coming within preferred power density levels usually ranging between 1-10 W/g depending on type of products under consideration (13). Over-heating could be avoided in this manner aside from maintaining good quality through fine adjustments through application models leading into simulation predicting heat dispersion.

Maintaining an optimal moisture content is also critical for preventing hot spots within the product, which could result in “overcooking” in localized areas. Moisture control strategies such as blanching and introducing controlled air flow to the microwave system are used at the pretreatment phase.Using these instructions alongside advanced sensor technologies, microwave processing can be effectively optimized to guarantee food safety, which is in alignment with industry standards.

Sterilization and Pasteurization via Microwave Techniques

In sterilization and pasteurization using microwave techniques, microwave energy is regulated to kill all harmful microorganisms responsible for causing diseases in foods as well as increasing the lifespan of these products. Normally, microwaves operate at power intensities during pasteurization, which facilitates temperature-time profiles that are capable of inactivating spoilage organisms and pathogens without affecting product quality. This process begins with fast heating followed by a holding step at required temperatures usually within 140-165°F (60-74°C) for pasteurization and over 248°F (120°C) for sterilizing. Another technical advantage is even heating, shorter time durations of processing coupled up with retaining sensory and nutritional values of products. A comprehensive approach involving state-of-the-art monitoring and control systems, however ensures reliable and consistent microbial reduction throughout entire food matrices.

Regulatory Standards for Microwave Drying Systems

Microwave drying systems have stringent industry rules directed at safety and quality of food products after being processed. Closely related to these are directives that the customer must be able to control heating by maintaining accurate temperature through precision. For example, the US Food and Drug Administration requires regular calibration of thermometers so as to confirm their accuracy, making sure that the device is operating within safe limits. Furthermore, European manufacturers are obliged to practice Good Manufacturing Practices (GMP) aimed at averting contamination and ensuring that moisture content is uniform across a given product. Furthermore, The United States Department of Agriculture (USDA) has guidelines which mandate routine assessments and maintenance inspections of equipment in order to verify compliance with food safety standards and regulations. Consequently, manufacturing firms should ensure they follow the above regulations, allowing effective operations of their microwave drying systems, thus achieving high-quality products without compromising safety.

How to Implement Microwave Drying Systems in an Industrial Setting?

In industrial settings, microwave drying systems can be put in place through comprehensive planning, installation and commitment to operational procedures. It is imperative that a proper needs assessment be carried out at the initial stages to determine specific drying requirements for items being processed. This involves analyzing factors like moisture content, ideal drying rate, and uniformity, which are key in preserving the quality of the product. After this stage, it is important to select the right microwave drying equipment with specifications that match these factors: power capacity, chamber size as well, and advanced features like temperature control and uniform heating should be considered. Professionals perform the installation so that they ensure its efficient integration into existing processing lines and safety standards are met. Training should be done regularly for workers to familiarize themselves with operating guidelines, maintenance duties, as well as security measures. Continuous monitoring and calibration of the equipment must also be performed in order to keep them working efficiently within regulatory limits, thereby generating consistent, high-quality results.

Steps towards Integration of Industrial Microwave Systems

- Initial Assessment & Planning

- Perform an all-inclusive needs analysis concentrating on specific drying requirements of the product.

- Check moisture content, dryness consistency and desired speed of evaporation to maintain product integrity.

- Include a clear implementation plan with timelines, resource allocation and budget considerations.

- Selecting Appropriate Equipment

- The required power capacity (usually measured in kilowatts) depending on your production scale is determined.

- Go for equipment whose chamber sizes will handle huge product quantities.

- Look out for hi-tech features such as temperature control systems that ensure even heating throughout all parts.

- Example: A typical industrial microwave dryer might range from 10 kW to 100 kW power capacity.

- Professional Installation

- Engage experienced professionals for system installation to ensure seamless integration within existing process lines.

- Ensure compliance with safety codes and standards during the installation process.

- Training & Operation

- Train staff on operational protocols with emphasis on adherence to safety rules and procedures.

- Have a maintenance program that includes cleaning time schedules, among others, like checking the microwave system’s calibrations, inspections, and cleaning that will make it perform to its maximum.

- Ongoing Monitoring and Calibration

- Continuous monitoring systems should be implemented to track key operating parameters such as temperature, power levels, drying time.

- Regular calibration is necessary for the microwave system to operate within set limits and maintain constant product quality.

- Where applicable make use of automated control systems which would guarantee precision and reduce human errors.

- Compliance & Quality Control

- Keep detailed records of operational data, maintenance activities, and product quality results to comply with industry regulations.

- Conduct periodic audits and quality checks to confirm the system meets the defined standards and specifications.

Microwave Heat Stove Installation Guidelines

During microwave heat stove installation, it is necessary to consider your specific operational environment. Start with a detailed site survey to determine where it should be installed best and make sure that the area has proper ventilation and space. Also, get in touch with a reliable distributor who will give you accurate specifications for the systems and advice regarding their compatibility with existing processes. In addition, prioritize systems with integrated safety features like auto shut off mechanisms or fail-safe controls which can help reduce certain vulnerabilities. Apart from that, all those providing assistance during the installation must be well-trained and conversant with this industry’s regulations as outlined by local authorities. Lastly, plan for an extensive commissioning process, including initial performance testing and validation, so as to verify that it complies with design parameters while achieving the efficiency and quality improvements desired.

Maintenance of Microwave Drying Equipment

It is important to frequently maintain and troubleshoot microwave drying equipment in order for it to optimally perform its functions. To start maintenance procedures, check all system components, such as magnetrons, waveguides, cooling systems, etc., which should be free of obstructions and remain in good working conditions on a regular basis. Clean inside chambers ridding them of any accumulated debris that may affect efficiency levels; monitor power outputs of microwave sources on a regular basis since reduction in powers could mean possible faults.

While troubleshooting, firstly, deal with any error message emanating from the control panel of the system referring to the manufacturer’s manual for diagnostic instructions as per code numbers written thereon. Common issues like uneven heating or reduced efficacy of drying might arise due to unequal material loading or blocked air filters; hence, confirming these facts would improve performance largely. Additionally, more challenging concerns like constant loss of power supply or failure parts may require professional support through advanced diagnoses and repairs carried out by specialists hired for that purpose alone. Usually routine software upgrades are also responsible for compatibility with newest technologies and keeping operational efficiencies intact.

Frequently Asked Questions (FAQs)

Q: What are the main benefits of microwave drying and heating systems for food processing?

A: Microwave drying and heating systems offer numerous benefits, including faster processing times, improved energy efficiency, and more uniform heating compared to traditional methods like drying rooms and convection ovens. These systems also help in maintaining the nutritional quality and sensory properties of the food.

Q: How does microwave technology improve the drying of liquid foods?

A: Microwave technology improves the drying of liquid foods by providing rapid and uniform heating. This method reduces the risk of thermal degradation, ensuring better quality and consistency of the final product.

Q: What types of food products can benefit from microwave drying systems?

A: A wide range of industrial food products can benefit from microwave drying systems, including pet food, snacks, fruits, vegetables, and meats. Particularly, microwave drying is quicker for high-moisture products, allowing for efficient processing and higher throughput.

Q: How does microwave drying compare to traditional drying methods like drying rooms and convection ovens?

A: Compared to traditional drying methods like drying rooms and convection ovens, microwave drying is quicker, more energy-efficient, and ensures uniform drying. It also minimizes the risk of over-drying and preserves the color, flavor, and nutritional content of the food.

Q: What specific frequencies are used in microwave drying systems, and why?

A: Microwave drying systems typically use frequencies of 2450 MHz and 915 MHz. These frequencies are chosen because they efficiently penetrate food products, providing uniform and rapid heating, reducing drying times, and improving overall process efficiency.

Q: What is the importance of tempering in microwave treatment?

A: Tempering in microwave treatment is crucial as it helps in ensuring uniform moisture and temperature distribution throughout the food product. This step is essential in preventing issues like uneven drying and overheating, thereby maintaining the quality and safety of the food.

Q: What role do ferrite microwave technologies (FMT) and industrial microwave systems (IMS) play in food processing?

A: Ferrite microwave technologies (FMT) and industrial microwave systems (IMS) play a significant role in food processing by providing optimized solutions for various thermal processing needs. These technologies ensure efficient energy use, better control over heating processes, and improved product quality.

Q: How do microwave drying systems contribute to energy savings in commercial food processing?

A: Microwave drying systems contribute to energy savings by using targeted microwave energy to heat and dry food products directly. This method reduces overall energy consumption compared to conventional thermal processing techniques, leading to cost savings and enhanced sustainability in commercial food processing.