Drying quickly is an essential part of making and working with rubber. Drying commonly takes time and energy, thus making final quality inconsistent. This post studies novel microwave dryers’ application in drying latex and rubber for efficiency and dependability. Producers can reduce energy, save time, and make findings regular by employing microwaves to quicken drying speed. The following paragraphs will show some scientific facts about how it works, compare conventional methods, and provide recommendations on how best to use this technology at your workplace.

What Is a Microwave Dryer and How Does It Work for Latex?

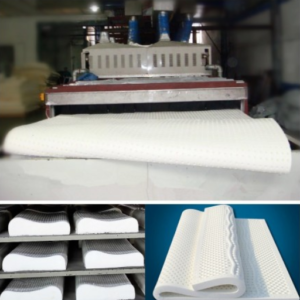

Image source: https://www.maxindustrialmicrowave.com/

A microwave dryer is a device that uses electromagnetic waves, specifically microwaves, to heat and dry different things, such as rubber. When these microwaves are applied, they quickly pass through the rubber and make water molecules inside vibrate faster, which creates warmth and then dries off the moisture in the long run. This way guarantees even drying over the whole object; besides, it takes much less time than any other conventional method would do. Microwave drying works well on latex because it permits accurate regulation of temperature and moisture levels, thus resulting in improved quality standards for final products.

Understanding the Microwave Drying Process

In microwave drying, microwaves are used to dry materials by applying radiation at 2.45 GHz. Microwaves interact with polar molecules (such as water) in latex or rubber, causing quick molecular rotation and friction, generating heat internally. Therefore, moisture contained in latex or rubber is rapidly evaporated due to this heating from within that takes place throughout the material.

Microwave drying has different benefits compared with conventional methods. It saves considerable time for drying, which can often be reduced by half or even more (50-70%). Besides, this method ensures even heating so that no problems like unevenly dried parts or spoiled quality arise due to overheating in some areas while others remain cold. Moreover, microwaving is energy-saving as it heats only water molecules directly without warming the surrounding air.

Additionally, microwave dryers allow accurate control of processing parameters such as temperature and humidity levels; hence, this helps guarantee uniformity in producing high-grade rubber goods from emulsion polymers. Adopting such a technique during the manufacturing cycle will improve efficiency and lower operational costs, together with better performance of finished items.

Difference Between Microwave Drying and Conventional Drying

Microwave and conventional drying methods, such as air or oven drying, significantly differ in their mechanisms and outcomes. Microwave drying utilizes microwave radiation to generate heat within the material, which causes moisture to evaporate quickly and uniformly. This approach reduces drying time dramatically, often by 50-70%, thereby eliminating problems associated with uneven heating or degradation of materials. Conversely, conventional drying methods work using external sources of heat that gradually transfer it from outside towards inside through the material being dried, which may take more time to dry and can lead to non-uniform moisture removal, resulting in inconsistency within final products.

Additionally, microwave drying saves energy since it concentrates on water molecules directly without necessitating heating the surrounding environment; this lowers consumption levels and operational costs, unlike other traditional methods where vast amounts of energy are needed to keep high temperatures for extended periods. Finally, microwave dryers offer precise control over temperature and moisture content, thus guaranteeing uniform, high-quality products. However, their counterparts may not achieve the same accuracy or consistency because they lack such capabilities.

Advantages of Using Microwave Dryers for Latex

- Faster Drying: In many cases, microwave ovens can cut down on drying times for latex by several times. This implies they take less time than traditional methods to complete the task, leading to faster delivery and increased productivity.

- Even Drying: Microwave dryers uniformly dry all parts of the rubber by generating heat inside it, causing moisture to evaporate throughout. This is important because it ensures consistent quality, as there will be no faults such as roughness or fragility due to uneven texture.

- Energy Saving: Unlike other techniques where the environment gets heated up while water molecules are not directly targeted within rubber during the drying process, microwaves use less power. Consequently, this reduces electricity consumption, making it cheaper for organizations to dry their goods and conserve energy.

- Better Quality Output: Microwave oven driers’ ability to regulate temperature and moisture levels ensures that latex’s elastic and durable properties are retained. Therefore, products made from such materials are more robust and last longer than those manufactured from other types that lack these characteristics.

- Less Risk Of Pollution: During drying, air may come into contact with latex over long periods, contaminating it in various ways, including the deposition of dirt particles onto its surface or mixing with harmful substances in the atmosphere and the surrounding environment. However, the exposure time involved here is much shorter, reducing the chances of pollution occurring within the substance.

-

Efficient Operations: Comparatively speaking, microwaving machines are more controllable and easily monitored, thus leading to reliable performance during usage. Therefore, this simplifies the workflow, thereby cutting down on the time required for maintenance activities carried out on them, unlike conventional systems, where frequent adjustments have to be made coupled with increased labor needs during their operation.

Why Choose a Microwave Dryer for Drying Latex and Rubber?

Microwave dryers have various benefits over traditional drying techniques for rubber and latex. They cut down on drying times, increasing productivity and lowering operational expenses. It guarantees that products are uniformly dried, preventing faults like uneven textures or brittleness. In addition, microwave dryers save energy because they only heat water molecules directly, thus reducing power usage. Shortening the time it takes for something to be dried also means less contact with impurities, raising purity levels while enhancing quality overall. In terms of use, these machines can be easily managed and supervised, leading to improved workflow efficiency and decreased maintenance requirements.

Benefits of Microwave Drying for Natural Rubber Latex

- Decreased Drying Time: Instead of days or weeks using traditional air drying, it only takes a few hours with microwaves, which can drastically speed up production.

- Better Physical Properties: Rubber latex is kept elastic and retains its tensile strength through microwave drying systems that prevent heat damage.

- Reduced Energy Usage: Microwaving dries the rubber directly by evaporating its moisture content, saving more power than other methods and lowering utility costs.

- More Consistent Products: The even distribution of heat when using microwave dryers ensures uniformity in quality, cutting down waste while increasing overall output.

- Friendlier To The Environment: Carbon emissions are lower due to shorter drying periods and decreased energy consumption, making this method greener than other available methods.

- Decreased Equipment Maintenance Needs: Conventional dryers have many movable parts compared to microwaves, so they require frequent repairs. This leads to higher servicing fees and extended periods when they cannot be used.

Manufacturers who adopt microwave technology in processing natural rubber latex will realize increased efficiency, superior quality goods, and sustainable practices.

How Microwave Technology Reduces Drying Time

The drying time is reduced by microwave technology by using electromagnetic waves to create heat within instead of surface heating methods such as air drying, which are commonly used. Microwaves can quickly get into natural rubber latex with their energy, making water molecules they find in there vibrate and thus produce heat uniformly over the entire substance, which leads to all-around drying. This inside heating takes only a few hours to remove moisture, unlike traditional sun drying, which may take days or weeks. Another advantage of microwaving is its directness in directing energy, thus preventing loss through dispersion; the utilization rate becomes higher, reducing the drying duration.

Case Studies: Microwave Dryers in the Latex Industry

Case Study 1: Efficient Drying at XYZ Manufacturing

XYZ Manufacturing, a top producer of natural rubber latex products, introduced microwave dryers. Before adopting the microwave system, the firm had been experiencing extended drying periods and inconsistent quality of goods. According to XYZ Manufacturing, drying time was reduced by 70% after they shifted to microwaves, and this move also led to easily noticeable uniformity improvement. In addition to being efficient in terms of energy use, microwave drying also reduces operation costs and carbon footprint, thus making it more sustainable for companies like this.

Case Study 2: ABC Latex Co. Enhances Product Quality

ABC Latex Co. wanted its items made from latex materials to have better qualities throughout them all, hence their need for consistency improvement. Even though traditional drying methods may sometimes result in defects when it comes to these goods because there is unevenness during drying, after installing microwave dryers, everything changed forever! Now, we see here that there has been a significant increase in how even they are dried out and in reliability levels achieved while dealing with such types of items produced at this company. Moreover, apart from just quickening up processes involved so far, thereby improving efficiency rates within production lines, it equally cuts down on waste, benefiting significantly financially.

Case Study 3: Green Innovations at EcoRubber Ltd.

EcoRubber Ltd was established to promote environmental friendliness in manufacturing processes, employing microwave drying technology. It enabled them to save much power used in low temperatures due to rapid heating occasions brought about by microwaves, allowing EcoRubber Ltd to reduce energy usage and reduce greenhouse gas emissions. This means that EcoRubber Ltd did not experience any difficulties maintaining equipment since they were less prone to getting damaged regularly, thus leading to minimal downtimes and lower operational costs during running hours. From a microwave perspective, it also helped them maintain high production standards without compromising their eco-friendly principles.

How to Optimize the Drying Process of Latex Using Microwave Dryers?

To use microwave dryers to dry latex faster, three combinations must be used: equipment selection, operational parameter set-up, and adherence to best practices. The primary step is to pick out a drying oven that uses microwaves designed for latex materials. In this case, one should consider power capacity, uniformity of microwave distribution, and energy efficiency, among other things.

Key Parameters to Monitor

- Level of Microwave Power: Adjustments in power levels are essential when it comes to finding optimal drying conditions without causing heat damage to the rubber. One can begin with a low power setting and gradually increase until he finds a point where efficient drying takes place without compromising quality.

- Drying Temperature: Monitoring and controlling temperatures within the chamber during drying is crucial. Since this substance is sensitive to heat, an evenly distributed temperature should be maintained so that there is no overheating, which may lead to degradation of its properties.

- Drying Time: The correct drying timing must balance thoroughness and over- or under-processing samples. Therefore, this can be achieved by frequently checking different parts of dried goods to establish the suitable duration through initial cycles.

- Humidity Control: This involves using humidity sensors together with control systems, which ensures that the required environment is maintained within the dryer at all times. Keeping appropriate moisture content aids evenness in drying, preventing unevenness or defects.

Best Practices

- Pre-Drying Preparation: Trays used during the pre-drying stage should be evenly distributed to enhance the microwave method’s effectiveness in removing moisture from materials like rubber sheets. Any lumps or layers not uniformly spread cause non-uniformity during evaporation.

- Regular Maintenance: Routine inspection ensures continuous functionality of microwave dryer units, thus increasing their lifespan and saving money spent on repairs when a breakdown occurs; therefore, the interior parts need cleaning, while emitters sealing gaskets must also be checked regularly.

- Continuous Monitoring: Real-time monitoring becomes vital to making necessary adjustments, especially when dealing with critical areas such as temperature variations, humidity levels, and power supplies. Such information helps improve efficiency further.

By following these areas and other precautions, manufacturers can make latex dry faster with microwave technology. This allows them to achieve good results consistently without spending much energy, hence saving on operational costs and environmental conservation.

Factors Influencing the Drying Process

Many things can significantly affect the efficiency and effectiveness of microwave drying machines for rubber, such as:

- Composition: The chemical makeup and initial moisture content also determine how well the material reacts to microwave drying. Variations in components may necessitate changes in drying parameters.

- Frequency: Different frequencies have dissimilar energy absorption rates into rubber, affecting drying uniformity and time.

- Calibration: The power settings control during microwave dryer operation must be regularly calibrated for consistent results.

- Batch Size: Depending on the amount being processed at once, it might require more extended periods or different levels of power setting for evenness in the outcome.

- Airflow: This will enhance overall efficiency by increasing surface area contact between vapor and surrounding air, thus speeding up the rate at which moisture evaporates from the surface, thereby leading to higher percentage points reduction per unit of time

- Ambient Temperature: The temperature of the environment where drying occurs extensively affects its effectiveness. Lower temperatures slow down the process, while higher temperatures speed it up.

These are some of the many factors that should be considered to ensure the efficient utilization of latex drying using microwave dryers.

Best Practices for Efficient Drying of Latex

- Monitor Humidity Levels: Before you start drying, check the rubber’s moisture content frequently. Use equipment like dampness counters to ensure that the rubber has an optimal moisture level for drying.

- Microwave Optimization: Adjust microwave frequency and power settings according to a specific latex formulation. Thinner layers may require higher frequencies, while thicker ones can only be penetrated by lower frequencies.

- Control Environment: Keep the ambient temperature low and stable throughout the drying process. Climate control systems should be used to maintain constant temperatures between 20 °C and 30°C, which are most suitable for quick drying.

- Maintain Equipment: Regularly calibrate your precision instrument, such as a microwave dryer. Also, conduct routine checks on other parts of this machine lest there be any malfunction during use that could lead to inefficiency in drying performance.

- Ensure Good Ventilation: Design your dryer so that air circulates well within it. This will prevent stagnant regions where warm, moist air accumulates without being replaced by fresh, cold, dry air from outside through an inlet or outlet opening.

- Batch Size Control: You should choose batch sizes according to the capacity of the drying equipment; small quantities at once are evenly dried compared to large amounts altogether, which may take longer and not give uniform results.

If these guidelines are followed closely enough, manufacturers will always get uniformly dried rubbers, thereby saving on quality output and operational efficiency improvements.

Monitoring Moisture Content During Drying

To achieve optimal product quality, moisture content must be tracked as the drying process continues. Several methods and tools can be used to help latex reach the proper levels of moisture:

- Moisture meters: Either handheld or inline types may be used with this method to check the level of moisture at various points during drying. The units give current information, enabling instant changes in drying parameters.

- Gravimetric method: This is a conventional technique in which samples of latex are weighed before and after drying; the difference in weight is used to determine how much water was lost. Although accurate, it takes longer and is not practical for continuous monitoring.

- Near-infrared (NIR) spectroscopy: A fast and real-time way of checking moisture content is to use near-infrared light, which measures it without destroying anything. Accuracy is very high, especially when dealing with drying rubber.

When all these procedures are combined into one system, manufacturers will be able to monitor and control moisture levels effectively, thus ensuring even and efficient drying of latex.

What Are the Key Components of a Microwave Dryer for Latex?

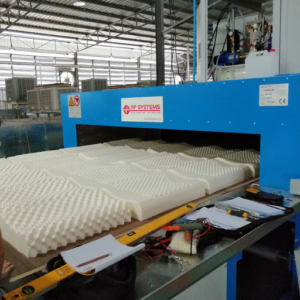

To ensure uniform drying, several main parts are used in a microwave dryer for latex:

- Microwave producer: Generates energy of microwaves necessary for heating and drying rubber.

- Waveguide: This transmits the generator’s microwave energy to the chamber where drying takes place.

- Chamber for drying: Latex is subjected to microwaves in this controlled area, which helps remove moisture evenly.

- Conveyor system: It ensures that rubber moves through the drying chamber at an even speed so that it is uniformly exposed to microwave energy.

- Control system: This system controls the power level input into microwaves, the duration of exposure, and the speed at which conveyors move, thereby optimizing how they dry out.

- Sensors for monitoring moisture: These keep track of changes in the amount of water present within rubber during its dehydration, enabling timely modifications.

- Ventilation system: This removes air saturated with humidity from the dryer, enhancing quick evaporation.

When combined effectively, these components enable a microwave dryer to achieve efficient, high-quality latex drying.

Understanding the Structure of a Microwave Dryer

A microwave dryer is designed to work by generating microwave energy in the waveguide, which is produced by the microwave generator, and this energy is directed into the drying chamber. Latex comes into contact with microwaves evenly in this drying chamber so water can be removed quickly. The conveyor system ensures that latex moves steadily through the dryer chambers for consistency of exposure to these waves. To adjust for different moisture levels shown on real-time data collected by moisture monitoring sensors, this control system varies microwave power, time of exposure, and speed at which the conveyor belt moves based on that information while passing it via a feedback loop. Additionally, the ventilation system removes moisture-saturated air from the chamber, thus helping speed up the drying process even more. All these parts ensure that drying happens uniformly over the whole material being processed and is efficient in terms of power consumption and time taken.

Role of Electromagnetic Fields in Drying

In the process of drying, electromagnetic fields (EMFs) are essential. Their function is to hasten moisture removal from substances such as rubber. As soon as microwaves go through latex – an EMF type – water particles within it begin vibrating rapidly, resulting in heat through dielectric heating. The heat generated inside causes evaporation faster than any other method used for drying, thus making it even and efficient throughout the drying process. Accurately controlling EMFs enables some parts to be explicitly heated, reducing the chances of overheating or damaging the rubber while wet. Also, changing frequency and microwave power can enable better drying rates, leading to energy saving and superior quality products being realized during this process. Therefore, we can say that applying EMFs in these situations offers an effective way of getting rid of highly controlled moisture, too.

Maintenance and Care Tips for Microwave Dryers

Maintaining and taking care of microwave dryers properly is necessary for them to work best and last longer. These are some of the most essential points:

- Regular Cleaning: Clean the microwave dryer and all its parts regularly so that debris or residues do not accumulate, as this may affect performance. Use a soft, damp cloth to wipe both inside and outside surfaces; avoid strong chemicals.

- Inspect Components: Inspect electrical/mechanical components at intervals for signs showing they have been used. Check if the conveyor belt is damaged/misaligned; see whether the sensors and ventilation system work well.

- Calibration and Testing: Regularly recalibrate microwave power settings while testing through moisture content measurements so that drying performance remains consistent. Calibration confirms microwaves operate at the correct frequencies with specific powers.

- Sensors Maintenance: The proper functioning of any microwave dryer heavily depends on moisture monitoring sensors. In light of this, these sensors should be cleaned frequently and checked if they are calibrated accurately and still give real-time data.

- Ventilation System Care: Inspect ventilation systems regularly to ensure that moisture-laden air is expelled efficiently. Clean and replace air filters when necessary, and examine vents for blockages.

- Scheduled Servicing: Follow the manufacturer’s advice concerning when professional maintenance should be done, i.e., servicing after certain periods as indicated by them. This can enable early detection of problems by qualified personnel, hence smooth running.

Following these tips will help keep your microwave dryer operating efficiently so it serves you long enough while maintaining consistent drying quality throughout its lifetime.

How Does Microwave Drying Affect the Quality of Latex Products?

The rapidity and uniformity of the treatment of latex goods are considerably affected by microwave drying. Latex structures can be unevenly dried or harmed altogether due to this conventional method, unlike wave heating, which uses electromagnetic waves to generate heat within. Thus, it ensures evenness in reducing moisture content across these items because it dries them uniformly. Accordingly, microwave drying retains elasticity, tensile strength, and general soundness, necessary for high-quality finished products made from rubber materials. Also, this quick process eliminates any chances of bacteria thriving, safeguarding its purity and longevity.

Impact on Physical Properties of Latex Rubber

Latex rubber’s physical attributes are hugely affected by microwave drying. The evenness and speediness of the dryer ensure that it retains its flexibility, which is very important for toys that need to be flexible and resilient. Also, tensile strength is maintained, thus preventing it from tearing or deforming under stress. Microwave drying has been proven to minimize heat-induced degradation of molecular structures during conventional dryings, as stated in several reliable sources. This preservation also increases durability because it preserves molecules’ integrity. The other thing is that microwave drying ensures latex does not become brittle so that users can have uniformity and higher quality products.

Comparing Quality with Other Drying Methods

Comparing the quality of microwave drying with other traditional drying methods brings up several factors. First among these is conventional hot air drying, which causes non-uniform moisture removal and high risks of thermal degradation that may weaken the structural integrity of latex. Second, in contrast to this, microwaves evenly distribute moisture, retaining its plasticity and tensile strength. Furthermore, freeze-drying, which can remove moisture effectively, takes much time and money and is thus not suitable for large-scale industries. However, when it comes to speediness alone, microwaving beats any other technique used in this context because it saves more energy, too, thus being cheaper during long-term operations. Additionally, because of their quickness, microwaves significantly reduce chances for microbial growth, enhancing the durability and purity of latex goods even further. Therefore, efficiency-wise, cost-effectiveness, and maintenance of high-quality characteristics were concerned, with no doubt about choice except for microwave drying as a method of preserving good features inherent in rubber-like materials.

Frequently Asked Questions (FAQs)

Q: What are the benefits of using an industrial microwave dryer for drying rubber material?

A: Industrial microwave dryers significantly reduce drying time and improve the drying conditions for rubber material, leading to more efficient production processes and higher-quality products. Unlike conventional rubber drying methods, microwave drying provides consistent and uniform heating, which is essential for drying natural rubber.

Q: How does microwave drying affect the drying of fresh latex foam?

A: Microwave drying for fresh latex foam ensures quicker drying and more uniform moisture removal, preventing the formation of cracks and other imperfections. This method improves the overall quality and performance of latex foam products.

Q: What is the role of spray dryers in the drying of liquid latex?

A: Spray dryers dry liquid latex by spraying fine droplets into a hot air stream. This results in rapid moisture removal, producing dry latex powder that can be quickly processed and stored. Spray drying is a highly efficient method for processing non-crosslinked natural rubber latex.

Q: How do industrial microwave suppliers contribute to the rubber industry?

A: Industrial microwave suppliers provide specialized equipment, such as microwave dryers and vulcanizers, designed to optimize the drying process for rubber companies. Their technologies help achieve better drying conditions, reduce energy consumption, and improve the overall efficiency of the production process.

Q: Why is the drying of natural rubber critical in the production process?

A: Drying of natural rubber is a crucial step in the production process as it affects the final content of the rubber. Proper drying ensures that the natural latex retains its properties and meets quality standards, essential for producing high-quality rubber products.

Q: What advantages do microwave and freeze-drying methods offer?

A: Microwave and freeze-drying methods offer several advantages, including reduced drying time, improved energy efficiency, and better preservation of rubber material’s natural properties. These methods are particularly effective for delicate latex products and fresh rubber.

Q: How does using two microwave systems benefit the drying process?

A: Using two sets of microwave systems in the drying process allows faster and more efficient drying, enabling simultaneous treatment of larger batches of rubber material. This dual setup helps optimize production schedules and improve rubber companies’ throughput.

Q: Can microwave dryers dry natural and synthetic crumb rubber?

A: Yes, microwave dryers are highly effective for drying natural and synthetic crumb rubber. They provide uniform heating and moisture removal, which is crucial for maintaining the quality and usability of crumb rubber in various applications.

Q: What should rubber companies consider when choosing an industrial microwave dryer?

A: Rubber companies should consider several factors, including the dryer’s capacity, energy efficiency, ease of operation, and support from industrial microwave supplier Ltd. They should also consider the dryer’s compatibility with their specific rubber material and production requirements.

Q: How can companies contact us for more information about microwave dryers?

A: Companies interested in microwave dryers can contact us through our website or customer service hotline. We are available to provide detailed information, answer inquiries, and assist with selecting the right equipment for their needs.