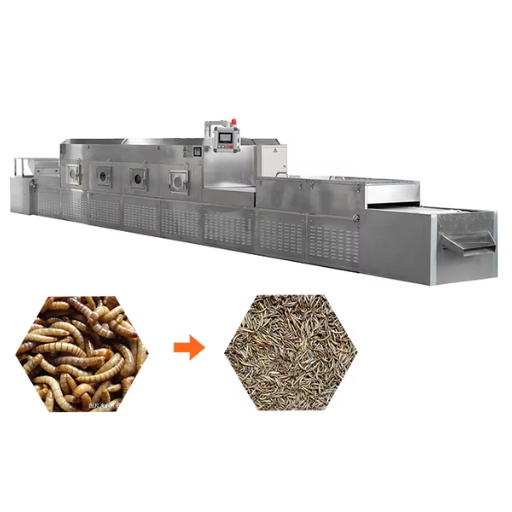

The search for sustainable and efficient food processing techniques has resulted in innovative strategies like using the black soldier fly (BSF) larvae for waste management and protein production. The Black Soldier Fly Larvae, Microwave Drying Machine, is leading this change; it presents a ground-breaking drying technique that conserves most nutrients but diminishes the drying time significantly. This article aims to examine how this technology works, its value concerning BSF larval processing, and its potential impact on agriculture and animal feed sectors. This paper will look into microwave drying science so that readers can get complete information about how it improves efficiency and supports a more sustainable food system.

How does a black soldier fly larvae drying machine work?

Image source: https://temaprocess.com/

Black soldier fly larvae drying machine works on drying the larvae by using microwaves, which help eliminate moisture efficiently. Through dielectric heating, microwaves rapidly generate heat that makes water molecules within the larvae vibrate and thus generate heat. In this case, a high rate of evaporation occurs with the preservation of nutritional qualities in the insects/soldiers. For instance, uniform dryness is achieved when the machine maintains optimum temperature and humidity levels during drying, thus preventing the degradation of essential nutrients. Unlike conventional methods that take too much time and require much energy, this innovation provides an alternative option for producing BSF larvae used as animal feed or other applications in a way that saves energy and protects the environment more effectively.

Understanding microwave drying technology

Microwave technology fundamentally uses microwave unique characteristics to quicken drying by directly activating water molecules contained in the dried material. There are several advantages of this method over traditional drying techniques. Firstly, it enables faster drying times because microwaves reach through the material in a uniform pattern, which helps reduce overall drying time. Secondly, lower heating temperatures help preserve nutrients and the flavor of the material, making such processing beneficial for food items and feed sources such as black soldier fly larvae. In addition, since microwave drying does not rely heavily on airflow; therefore, it reduces the need for fossil fuels and lowers energy consumption leading to sustainable approaches in various industries associated with drying processes. Usage of this technology leads to higher efficiency levels and better product quality among food and feed producers with minimal environmental damage.

Benefits of using an industrial microwave for fly larva drying

There are several advantages to using an industrial microwave for drying fly larvae:

- Speed and Efficacy: Industrial microwaves, as compared to traditional means of drying, reduce the drying times tremendously, hence making it possible for producers to process large quantities of larvae within shorter periods. This efficiency not only increases productivity but also cuts down on labor costs.

- Retaining nutrients: Lower temperatures in microwave drying helps preserve essential nutrients and enhance the overall quality of dried larvae. This is very important for animal feeds that need nutrient density.

- Energy Saving: Microwave dryers consume less energy than traditional dryers, thereby reducing energy consumption significantly, which can save on costs. This reduces carbon footprint, thus contributing to both operational savings and sustainability.

- Quality Control: Industrial microwaves can reduce problems like over- or under-drying through precise control over the drying process, thus reducing product inconsistencies. As a result, feed production standards will be upheld due to uniformity in these parameters.

Manufacturers can increase their processing capabilities while at the same time promoting environmental sustainability and maintaining product quality by capitalizing on these benefits.

Steps involved in the drying process for BSF larvae

The drying process for larvae of the Black Soldier Fly (BSF) consists of the following main steps:

- Harvesting: First, harvest the BSF larvae at their prime stage of development to obtain maximum nutrient content.

- Preconditioning: Prior to drying, the larvae may be subjected to preconditioning, which involves washing and removing impurities. This ensures an effective drying process and maintains product quality.

- Microwave Drying: Put the pre-conditioned larvae into an industrial microwave oven. The drying process involves applying microwave energy, which heats the larvae, causing rapid evaporation of moisture while preserving nutrients.

- Monitor Temperature and Time: During the dry phase, it is essential to observe the temperature and duration of drying to prevent overdrying. This ensures even moisture content across all larvae.

- Cooling and Storage: After attaining the desired moisture level, allow them to cool down before packaging. To retain its quality and avoid spoilage, appropriate storage conditions must be maintained

Suppose these procedures are followed to the letter by manufacturers. In that case, their black soldier flies (bsf) will be effectively dried, resulting in animal feed and other applications products having high standard qualities.

What are the key features of the BSF larva microwave drying machine?

- Energy Efficiency: The machine uses microwave drying, which significantly reduces energy consumption compared to other conventional drying methods.

- Even moisture removal: This characteristic guarantees a consistent quality of products as it ensures that every individual larva loses water at the same rate.

- Temperature Control: A highly accurate sensor system allows for fine-tuning adjustments that prevent burning up or losing nutrients.

- Automation: Some models have automated steps for loading, drying, and unloading larvae, which increase productivity and reduce labor requirements.

- Compact Design: The machine’s compact size makes it ideal for use in both small-scale and large-scale production facilities.

- User-Friendly Interface: It is usually accompanied by easy-to-use control panels and displays that let operators monitor the drying process easily and make changes accordingly.

- Safety Features: Emergency shut-off systems and protective casings, among others, are some safety measures to protect workers and equipment involved.

Through these features, the BSF larva microwave dryer is an integral tool in ensuring the effective processing of high-quality larvae.

Design aspects of the drying equipment

Top industry sources point out some essential things when designing BSF larva microwave drying machines. First, insulation and thermal efficiency are crucial in reducing energy loss during drying so that heat is used well. An ergonomic layout is also essential; designs often incorporate easy access for maintenance and monitoring, facilitating operational efficiency. Many machines also have modular designs, making them grow as production needs increase. Material choice is another crucial factor; corrosion-resistant and food-safe materials enhance durability and maintain product integrity. Finally, incorporating HVAC systems for controlling humidity levels promotes optimal drying conditions and prevents moisture reabsorption. These design aspects determine how efficient, long-lasting, or valuable a machine can be in various production environments.

Efficiency advantages of microwave drying over traditional methods

The advantages of microwave drying in larvae processing include improving efficiency. Firstly, it permits quicker drying periods as microwaves are directed to the product, causing the moisture content to heat up instead of using external sources for heating. This makes it possible for the process to take less time to achieve a higher throughput. Secondly, microwave drying tends to work at lower temperatures, thus minimizing heat damage risks, protecting their nutritional value, and enhancing uniformity in production. Also, energy consumption is often reduced compared with traditional techniques, which helps cut operational costs. Moreover, microwave drying provides better control of the drying process, making it possible to make real-time adjustments, which would help achieve evenness and prevent further drying. Lastly, they have a compact design, meaning that floor space can be saved, making them suitable options for manufacturing businesses seeking optimization opportunities.

Applications of the black soldier fly larvae drying machine.

The black soldier fly larvae drying machine has diverse applications in various industries, especially sustainable agriculture and waste management. One of them is making animal feeds with high levels of protein, where dried larvae are used as a source of high-quality poultry, fish farming, and livestock food ingredients. It also adds value to the nutritional content in feed and, at the same time, fits into a circular economy through food waste reduction since the larvae can be reared on organic by-products.

Moreover, it can be used to make pet foods and treats in response to the increasing demand for eco-friendly materials in the pet industry. In addition to this, there is potential for processing dry dead black soldier fly larvae into bio-fertilizers to enrich nutrients for soil health improvement and increased agriculture productivity. This adaptability demonstrates how helpful it is to ecological approaches, leading to money-spinning wares spanning different markets.

Why choose industrial microwave technology for BSF larva drying?

Industrial microwave technology has several benefits in drying black soldier fly larvae. To begin with, it quickens the drying rate by warming up moisture inside the larva; this reduces the time required for drying compared to conventional methods. Doing so saves energy and enables large quantities to be produced. In addition, they can control their microwaves precisely so that there is no overheating or damage done to the nutritional value of these insects, which will retain their essential oils and proteins. Furthermore, the technology can be scaled up, making it suitable for small and large-scale facilities. By using microwave technology, manufacturers can improve the quality and efficiency of their operations and ensure sustainable practices in the agriculture sector.

Speed and uniformity of drying

The speed and uniformity of drying black soldier fly larvae via industrial microwave technology are improved. Recent studies have found that microwave drying reduces the drying time by effectively passing through microwaves to larvae, hence the quick removal of moisture without compromising quality. As such, these short dry periods allow for a homogenous drying process so that there is no risk of any part getting more moisture than others, causing spoilage or loss of nutritional value. Additionally, This controlled environment during microwave drying ensures minimal thermal stress, giving the product optimal moisture content while retaining essential nutrients. Therefore, this capability positions microwave technology as the best option for manufacturers who wish to increase the efficiency and quality in drying black soldier fly larvae.

Impact on the nutritional value of BSF larvae

The nutritional value of larvae from black soldier fly (BSF) can be affected considerably by the drying technique employed. Research shows that microwave drying is more efficient than traditional methods in maintaining essential proteins, fatty acids, and vitamins, among other nutrients. This method helps to keep beneficial fats and essential amino acids in the larvae that are important for human consumption and animal feed by minimizing exposure to high temperatures and reducing drying times. Besides, scientific research has shown that larvae dried through microwave technology have higher protein content and lower levels of harmful bacteria, ensuring their safety and nutritional value. Therefore, manufacturers should embrace this advanced drying process to produce better quality products for feeding purposes of different livestock species, including fish farming.

Cost-effectiveness in industrial settings

This dry method, effective for industrial use, is highly efficient and dramatically reduces operational costs. It only takes a short time to dry using microwave technology compared to traditional drying methods, which take more time and require more energy. In addition, manufacturers can save on energy costs by using microwaves to heat only the product rather than heating the surrounding air, supported by recent research. Furthermore, reducing drying times speeds up production rates and reduces labor expenses, making it an economically attractive option. When industries are looking for sustainability options, the ability of microwave technology to bring down costs and maintain quality positions it as one of the best in the commercial drying market. Its efficiency and cost savings ensure profitability enhancement without compromising on quality standards, thus making it appealing to their businesses.

What are the benefits of microwave drying for black soldier fly larvae?

Microwaving drying is beneficial to black soldier fly larvae for several reasons. Firstly, it decreases the time required for drying, thus increasing their speed of processing and improving productivity. Secondly, it leads to more protein concentration in the larval organisms, enhancing their feed value. Furthermore, this procedure helps limit bacterial contamination, making it safe for consumption. Moreover, microwave drying enables temperature control with better accuracy than traditional methods, lowering thermal decomposition hazards. All these factors combined improve safety margins and nutritional aspects while reducing operational overheads, making microwave drying a useful method for processing black soldier fly larvae.

Enhanced shelf life and preservation

Black soldier fly larvae have a longer shelf life and are preserved through microwave drying. It is important to note that moisture content, one of the most crucial factors in deterring the growth of spoilage microorganisms and fungi, can be effectively removed by the rapid drying process. As indicated in research, it enhances shelf life by making products of long-lasting quality. Moreover, during microwave drying, regulated temperature settings aid in conserving the nutritional constituents of these insects, including vital vitamins and proteins that they contain for a more extended period. This ability to preserve better is advantageous not only for storage but also for improving larval marketability at large.

The environmentally friendly drying process

Notably, the microwave drying process for black soldier fly larvae is environment-friendly because it conserves energy. In contrast to traditional drying methods that usually involve high temperatures and long processing times, microwave dryers work on the principle of electromagnetic waves, causing water molecules inside food to vibrate. As a result, moisture removal is accelerated with minimal energy required. In addition, less external heating is needed, resulting in lower carbon emissions and achieving sustainable goals. Furthermore, microwave drying offers better control over emissions related to energy consumption, thus enabling it to become an eco-friendly option in processing larvae and ensuring their final quality. Overall, this method strongly ties in with ecologically responsible practices in food production.

Reduction in drying time and energy consumption

Unlike traditional methods, microwave drying considerably reduces the time it takes to dry a product and the amount of energy used. According to studies, microwave drying can decrease drying times by 50%, thus making it an ideal choice for processing black soldier fly larvae. The decline can be attributed to the direct heating of water molecules, which speeds up moisture evaporation. In addition, surveys from reputable sources point out that microwave drying uses less energy, usually reducing overall energy costs by at least 30%. It is a combination of fast drying and reduced energy usage that improves production efficiency and corresponds to the increasing desire for sustainable practices in food processing.

How do you maintain and operate a BSF larva drying machine?

Several steps are essential to ensure efficiency and longevity when maintaining a black soldier fly (BSF) larva drying machine. The first process is to regularly check the microwave compartment and dryers for cleanliness so that no accumulation of dirt can hinder performance. Also, ensure that the appliance’s cooling system works correctly to avoid overheating, which might destroy its internal mechanism. Moreover, it’s vital to set the moisture content calibration levels by adjusting power levels and drying times based on them. Finally, regular inspections of electrical connections and safety devices will ensure safe operation. By adhering to these rules, productivity will be enhanced, ensuring quality throughout the drying process.

Regular maintenance tips for optimal performance

Ensure your black soldier fly (BSF) larva drying machine functions at its best by adhering to these maintenance tips:

- Clean daily: wipe the inside of your microwave every time you use it, this help prevent moisture and residue buildup using a suitable cleaning agent which will not destroy the appliance.

- Check for tear and wear: Check all parts, including dryer trays and heating elements, as they can wear out faster. This way, efficiency is maintained since any worn-out parts are replaced promptly.

- Calibrate regularly: Periodically verify and readjust the moisture sensors to obtain accurate measurements that can be used effectively to change drying periods and the strength of different groups.

- Ventilation: Ensure there is no blockage in the ventilation system. The appropriate airflow is vital in maintaining safe temperatures and improving drying efficiency.

- Safety inspections: Carry out complete safety inspections, such as inspection of electrical components or safety interlocks, to ensure proper functioning according to the requirements regarding safety matters.

By doing so, you extend the life span of your dryer while still ensuring high production efficiency.

Operational safety measures

To guarantee the smooth running of your black soldier fly (BSF) larva drying machine, consider implementing these measures that have been derived from best practice trends:

- Training and Education: Ensure that all operators are well-versed in the machine’s working principles and safety measures. Regular training can help reinforce safe practices and keep staff updated on new safety information.

- Personal Protective Equipment (PPE): Provide each operator with appropriate PPE, such as gloves, goggles, and masks, to avoid injury due to heat and exposure to materials.

- Emergency Procedures: Clearly define emergency shutdown procedures and ensure everyone knows them. Emergency exits should be easily accessible, while an off switch should be clearly labeled.

- Regular Safety Audits: Maintain regular auditing of safety practices, which can help identify possible hazards or areas for improvement; however, checks for compliance with safety regulations and ensuring that all safety equipment is functional should also be conducted.

Following these operational safety precautions will greatly minimize the risks involved in using a BSF larva drying machine, thus fostering a safer work environment.

Troubleshooting common issues

Many usual challenges may occur when using the black soldier fly larva dryer. Here are some troubleshooting tips to use from current leading sources:

- Uneven Drying: When the larvae are not drying uniformly, this could be due to wrong airflow. Check for any blocks in the machine’s ventilation and confirm if it is working according to the recommended airflow rate. Cleaning these filters and fans regularly will also help maintain a good efficiency level.

- Too Hot: An overheating machine indicates very high-temperature settings or a fault with the temperature control system. Ensure you have adjusted your settings properly and examined heating elements for dirt or damage. If you cannot solve that problem, consult the manufacturer’s manual on checking parts out and changing them.

- Strange Sounds: Any unusual noise during operation can suggest mechanical problems like worn-off bearings or loose components. Regular checks of malfunctions and timely tightening or replacement of parts help prevent the escalation of such issues beyond this point. It’s recommended that you get professional help if you cannot trace where this sound comes from.

These troubleshooting instructions ensure prompt resolution of common problems, thus ensuring the smooth running of a BSF larva drying machine.

Frequently Asked Questions (FAQs)

Q: What is the Black Soldier Fly Larvae Microwave Drying Machine?

A: The Black Soldier Fly Larvae Microwave Drying Machine is an industrial microwave dryer used to dry and sterilize BSFL quickly while preserving its nutritional value. It effectively reduces drying time and ensures the larvae retain their original color and quality.

Q: How does the microwave dryer work for BSFL?

A: The microwave dryer uses electromagnetic waves to heat the insects from the inside out. This process, combined with a hot air system, speeds up the drying process and ensures uniform drying and sterilization.

Q: What are the benefits of using a microwave dryer for insect drying?

A: The benefits include a short drying time, efficient sterilization, and preserving the insect’s original color and nutritional value. Microwave-dried insects could maintain higher quality compared to traditional methods.

Q: Can the machine be used for other insects besides BSFL?

A: Yes, the machine can be used for drying and sterilizing a wide range of insects, including mealworm larvae and other larvae maggots. Its versatility makes it suitable for various insect drying applications.

Q: What is the capacity of the Black Soldier Fly Larvae Microwave Drying Machine?

A: The machine comes in various capacities tailored to different production needs. For specific capacity information, please get in touch with us at [email protected] or visit www.maxindustrialmicrowave.com.

Q: What types of raw material can the microwave machine process?

A: In addition to BSFL, the microwave machine can process various raw materials, including mealworms, larvae maggots, grain, and other solid biological materials that require efficient drying and sterilization.

Q: How does the drying chamber function in the microwave machine?

A: The drying chamber evenly distributes microwave energy to ensure that each raw material dries uniformly, whether BSFL or other insects. This controlled environment helps maintain the dried material’s original color and quality.

Q: What safety features are included in the larvae dryer?

A: The larvae dryer has multiple safety features, such as temperature control, automatic shut-off, and conveyor systems, to ensure safe and efficient operations. It also includes sterilization machines that meet industrial safety standards.

Q: Who should I contact for more information on the BSFL Microwave Drying Machine?

A: For more information, please contact us at [email protected] or visit our website at www.maxindustrialmicrowave.com. Our team is ready to assist you with all your inquiries about purchasing and operating the machine.