The food processing industry today requires more efficiency and better quality. This can be achieved through thawing and drying, currently used in this sector. Nonetheless, they may take long hours to complete, thus reducing the nutritional value and texture of food products. However, with advanced technology, automatic microwave thawing systems for drying foods have been introduced, which is regarded as a new era of innovation. These state-of-the-art solutions are characterized by quickness, evenness as well and energy-saving methods that keep food safe while minimizing garbage output and making work more accessible in the factories. In this blog post, we explore how these game-changing equipment work, their benefits over traditional ones, and their transformative effects on the food processing industry. Whether you’re an expert in the field or just interested in the latest trends in culinary science – read on!

What is a microwave thawing system?

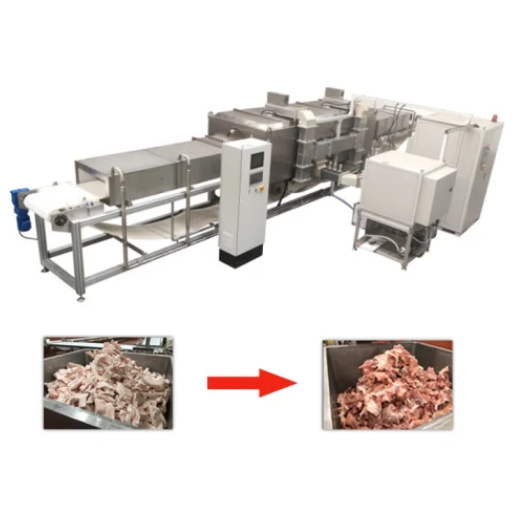

Image source: https://www.alibaba.com/

A microwave defrosting system is a highly developed technology that uses microwave power to quickly and uniformly thaw frozen food products. Inefficient and inconsistent traditional defrosting methods are replaced with microwave defrosting systems. These systems function by propagating microwaves through the food, which results in the vibration of water molecules, thus generating heat and heating from inside, which speeds up thawing, ensuring evenness and significantly reducing the time taken. The system can manage temperature precisely while minimizing loss of texture and nutrition, making it perfect for modern food processing plants.

Understanding the microwave thawing process

Microwave thawing involves heating food inside and out using electromagnetic waves to defrost it thoroughly. Microwaves make water molecules rotate quickly when they penetrate frozen meals, producing frictional heat. This approach allows even thawing, thereby cutting down on duration compared with air or water bath thawing, which other conventional methods would do. Microwave defrost systems usually come fitted with sensors that monitor temperature accurately, ensuring that no part of the food gets overcooked while still guaranteeing thoroughness in melting all parts down. For efficiency purposes in terms of energy utilization during heating, these appliances have gained popularity within different sectors of the food industry. Apart from flavor preservation capability, they also help retain nutritional value and keep texture intact.

How does an industrial microwave thawing machine work?

By emitting microwave radiation, an industrial microwave thawing machine can defrost the frozen food products from within; this is achieved because the microwaves can penetrate deep into these products, thereby causing water molecules present in them to vibrate, producing heat internally. Usually, such systems come with sophisticated sensors for accurate temperature control so that overheating or partial thawing does not occur; besides, many of them have conveyor belts that enable continuous processing and automated controls for optimization of speed and uniformity in thawing. What is more, while traditional methods may take long hours or even days before achieving desired results – these pieces of equipment are designed in such a way that they only need a few minutes to complete the process without compromising on the texture, flavor, and nutritional value of food compared with other ways.

The benefits of microwave thawing equipment

There are several benefits provided by microwave defrosting equipment over conventional methods. The first one is that it drastically reduces the time needed for thawing, thus making processing faster and more efficient. This fast mode prevents the development of pathogenic bacteria, thereby improving safety measures taken when handling perishable goods. Secondly, uniform heating, which helps maintain the prepared dish’s texture, taste, and nutritional quality, can be achieved by using microwaves for defrosting purposes. Thirdly, energy consumption in such devices is deficient, making them cost-effective to operate throughout their life cycle; also, modernized systems have susceptible detectors alongside automation features that make sure temperatures are controlled accurately during this stage; hence, there will always be evenness in outcomes produced where over freezing or under freezing does not happen at all times.

How does microwave drying technology work?

Microwave drying technology uses microwave radiation, which eliminates moisture from stuff quickly. These heat waves create energy within the material by shaking its water molecules and evaporating quickly. Compared to other systems, this interior heating ensures faster and even drying because it uniformly affects all parts of the material. In addition, accurate control over power levels and duration for microwaving guarantees that the best possible result is achieved during drying without compromising the quality of processed materials. Consequently, the drying time is significantly reduced while improving energy efficiency and product quality.

Principles of microwave drying

Microwave drying depends on a dielectric heating concept, where, in this case, microwaves are used to get inside the substances, causing internal heat generation due to rotation and vibration exhibited by water molecules when subjected to them. Such warming accelerates the rapidity with which moisture disappears because it promotes uniformity in how things lose their wetness through evaporation. It should be noted that unlike those drying methods, which are based on surface warming alone, there is a more consistent distribution of energy during the microwave drying process, which reduces the chances of overheating, thereby preserving the integrity and goodness inherent in any given matter or thing being dried. Furthermore, microwave dryers save electricity since only water molecules are targeted, thus minimizing wastage while shortening the overall period used in getting rid of moisture.

Applications of an industrial Microwave Dryer

Industrial microwave drying machines have numerous uses in many different sectors. When it comes to the food industry, they help dry fruits, vegetables, spices, and herbs, significantly reducing the time taken for drying while still preserving their nutritional value and taste. In the pharmaceuticals sector, this type of dryer is used for faster and more uniform drying of active ingredients (APIs) or finished products than any other traditional method can do. The chemical industry uses them to dry powder forms such as granules, ensuring consistent quality standards during production without causing too much downtime between batches. In contrast, the wood & paper industries apply microwave dryers for rapid, even moisture removal, thereby stabilizing products better against various defects like warping, which may occur if left unchecked for extended periods under normal conditions. These examples show how important these machines can be in enhancing productivity and improving product quality and energy efficiency across different fields of application.

Efficiency of microwave drying equipment

Microwave drying machines are renowned for being much more efficient than other dryers. It does this by using microwave radiation to heat the water molecules in the material directly to quicken and even out its drying process. As per leading current sources, some significant benefits are that it shortens drying times by half or more; it cuts down energy usage significantly, thus saving money on bills and helping environment conservation efforts; also, higher quality products are achieved due to these processes being faster and less harsh on them. Another thing about microwaves is that they can be used in places where speediness, power-saving measures, or preservation of materials’ properties during their treatment are essential – this makes such machines highly effective for all industries that deal with time limits, energy efficiency requirements, and needful care for raw stuff.

Why choose automatic microwave systems for frozen meat processing?

Automatic microwave systems for the treatment of frozen meat have several good points. In the first place, they guarantee rapidity and uniformity in defrosting, thereby cutting down on time spent during processing, which also improves efficiency. This technique also safeguards wholesomeness and freshness by stopping ice crystals from forming, which can damage cellular structures. Furthermore, microwaves are highly energy-saving, reducing operational costs while supporting sustainable practices simultaneously. Their automation capabilities eliminate or significantly reduce manual input, thus cutting labor expenses and lowering cross-contamination risk. In summary, these machines are strong enough to help increase output while maintaining the quality standards required for treating refrigerated meats automatically.

Advantages of automatic microwave frozen meat beef thawing machines

There are several distinct advantages to automatic microwave frozen meat beef thawing machines. The foremost of these is speed and consistency; fast defrosting ensures that meat is uniformly defrosted and ready for further processing within a shorter time. The faster the thaw occurs, the quicker it will be processed, thus reducing bacterial growth risk during slow defrosting. In addition to being highly energy-saving, it cuts down on the costs of running them. It reduces their environmental impact by using less power than any other method would need otherwise. It does not require much human labor because most work is done automatically, lowering labor expenses significantly while minimizing mistakes made by humans due to tiredness or oversight, among others. On top of this, microwave ovens can keep the integrity and texture of the flesh intact while defrosting it, as large ice crystals formed during this process may ruin the cellular structure of the product, making it unpalatable for consumers – ensuring better quality products overall! These pros make them prudent investments towards higher productivity levels at lower costs within any meat processing industry where quality control matters most.

Quality and speed of microwave frozen meat

Microwave defrosting devices have been made for fast and even thawing, thus maintaining the quality of the meat. Based on leading experts in this field, microwaving reduces thaw times by a significant percentage compared to traditional methods while still allowing the handling of large amounts of meat. Slow defrosting methods can cause bacterial contamination, which is not the case with this quick process. Also, giant ice crystals that destroy texture and cell structures within meats are prevented from forming during microwave thawing, thereby preserving its quality. Therefore, speediness guarantees good results, which is why most establishments involved in meat processing prefer microwave-defrosting machines.

Comparing traditional thawing methods with microwave thawing

Refrigerator thawing, cold water thawing, and room temperature thawing are three traditional ways of defrosting meat used in the meat processing industry for a long time but have also been associated with several drawbacks. Safe though it may be, refrigerator thawing is a slow process that can take as long as twenty-four hours to defrost large amounts of meat, leading to production delays. On the other hand, cold water thawing is much quicker; however, it has to be done under constant monitoring, and water must be changed continuously to prevent bacteria from thriving, making this method labor-intensive. Room temperature thawing is not recommended because it creates an ideal environment for bacteria growth, which could result in food poisoning.

Microwave defrosting, unlike any other method so far known, saves not only time but also energy significantly. Microwave speediness mitigates risk by keeping food temperatures out of the danger zone, where bacteria multiply fast, mainly in the few minutes needed to reach desired temperatures through microwaving. Like no other process before it was seen or since discovered, evenly distributed energy within microwaves enables meats to retain their natural texture and quality by preventing the formation of extensive ice crystals. At the same time, traditional methods usually bring about patchy defrosting microwave ensures uniformity thereby raising efficiency levels during production stages in meat processing factories. Such refashioned sentences will continue being utilized throughout this entire response.

What are the critical components of an industrial microwave system?

An industrial microwave system is made up of several components that are necessary for its efficient and effective operation. Some of these components include:

- Magnetron: This is the heart of a microwave system. It produces microwaves by converting electrical power into high-frequency electromagnetic waves.

- Waveguide: A waveguide directs the microwaves from the magnetron to the cavity, where the product is placed. The primary purpose of this component is to ensure an even distribution of energy.

- Cavity: A cavity or cooking chamber, as some people refer to it, creates an enclosed space within which processed products are located. It ensures containment and proper utilization of microwave energy.

- Control System: A control system consists of controls and software required for adjusting microwave power, duration, and other parameters depending on specific processing needs.

- Cooling System: The magnetron and other parts should always be kept at optimum operational temperatures; hence, a cooling system becomes necessary. This prevents overheating, thus maintaining consistent performance.

- Safety Interlocks: These mechanisms do not allow the operation of a microwave system when the door is open or in case a fault is detected; they prioritize safety for workers and the equipment involved.

- Conveying System: In continuous systems, transport like a conveyor belt moves products through evenly distributed fields so that large-scale processing can occur effectively.

All these components work together to ensure higher quality results during meat processing, among other industrial applications that use microwaves.

The role of the microwave generator

The microwave generator in industrial microwave systems is often called the magnetron. Its main job is to produce the energy microwaves use to process things. That being said, it converts electric energy into electromagnetic waves of a higher frequency than average and then sends them through a waveguide and into the cavity where the product sits. The more uniform heating or drying achieved through this process is necessary to maintain uniformity in quality among products. Furthermore, the efficiency and effectiveness of these machines dramatically depend on what kind of power supply they have, which means that without good supplies like those found in meat processing plants, there will be no success at all.

The importance of microwave energy distribution

Energy allocation of microwaves is necessary for the efficiency and effectiveness of industrial microwave systems. If the distribution of energy is uneven, there will be areas with too much heat while others will have very little, resulting in an inconsistent quality. This means that if you distribute energy uniformly, it will ensure that every part of the product gets processed equally, thereby improving quality and safety measures that are put in place to achieve ultimate consumer protection against any health risks associated with such products. In meat processing, for instance, if some parts are cooked more than others due to uneven heating, they might become tough or dry, thus affecting their taste negatively, too. Different ways, like using mode stirrers, among other advanced designs applied in waveguides and cavity structures, can optimize energy distribution within these systems. So what does this mean? By ensuring evenness when delivering power to objects being treated by microwaves during industrial operations, we aim to get consistent outcomes, saving time and enhancing productivity levels across different applications.

Maintenance and operation of an industrial microwave oven

Prolonging its life and optimal performance heavily depends on the proper care and usage of an industrial microwave oven. Essential steps are regular checks and cleaning because some residues may pile up, making it not work well and become more unclean. The magnetron, waveguide, and cavity should be examined by operators frequently for signs of wear or damage; parts should be replaced when necessary to avoid downtime. We must follow what manufacturers have said about operating this equipment safely while ensuring it works effectively.

Uniform energy distribution must be ensured by following recommended load sizes and configurations during operation so that overheating does not occur in some areas. Apart from monitoring performance using built-in diagnostics systems with alerts, personnel needs to address all problems in time for consistent product quality throughout system functionality checks; if these things are done, then different types of industries will benefit a lot from reliable results achieved by them when working with microwaves for industrial use.

How does microwave defrost technology improve food safety?

Food safety can be enhanced through microwave defrost technology as it helps thaw frozen foods much faster. Traditional methods sometimes allow food to stay at dangerous temperatures for long periods, unlike this method, which hastens the change of state from ice-cold to cook-ready, thus shortening the time during which bacteria may breed. This quickened procedure ensures that meals are kept safe and sound, preventing possible cases of food poisoning while ensuring that what is defrosted can be eaten without harm. Moreover, many systems for microwave defrosting have accurate controls on both timing and temperatures, which add to their reliability in terms of safety provisions throughout defrosting.

Reducing bacterial growth with microwave defrost

The temperature danger zone (40°F – 140°F) is where bacteria multiply fastest. Therefore, defrosting food should take as little time as possible. Microwaves can thaw frozen things more evenly and quickly than other methods because they reduce bacterial growth. Unsafe temperatures are reached by the outer parts of the meal while inside, it is still frozen, which is a problem with slow defrosting often experienced. Furthermore, contemporary microwave systems for thawing have sensors plus clever programs that allow them to modify cycles in response to conditions to achieve optimal heat distribution during this process, thereby minimizing chances of unevenness in warming up. That makes such defrosts safer but, more importantly, consistent with preservation standards for edibles at all times.

Consistent and uniform defrosting with industrial systems

Industrial defrost systems using microwaves have high-tech features that guarantee even thawing of vast amounts of frozen food. Per a few of the best sites, this system utilizes smart sensors and accurately regulated microwave strength to keep tabs on and correct the thawing process in real time. What this does is prevent areas with extreme heat or cold in the food by ensuring that there is an equal distribution of temperature throughout the product. Moreover, these systems are designed for efficiency in dealing with large-scale operations, enabling businesses to uphold quality and safety standards while meeting their production needs. This leads to a dependable defrosting method where bacteria do not thrive, keeping it fresh and preserving its texture and taste.

Safety standards for microwave thawing equipment

To ensure the safety and quality of food, microwave thawing equipment must comply with strict safety regulations. The top websites now state that microwave thawing systems should conform to standards imposed by organizations like the FDA (Food and Drug Administration) or NSF International. Commonly demanding food-safe material construction, close temperature control, overheating prevention measures during defrosting that is also uneven; these rules usually need frequent maintenance plus recalibration of sensors for consistent performance too. Such steps help businesses avert any health hazards related to microwaving things by ensuring they do not become breeding grounds for harmful bacteria or lose their original texture and flavor after defrosting.

What industries benefit from microwave thawing and microwave drying?

Microwave thawing and drying are helpful in various sectors. One of them is the food processing industry, which requires defrosting to be quick and even to maintain the quality and safety of products. The pharmaceutical sector also benefits from these methods when dealing with temperature-sensitive compounds because they aid in their stability and effectiveness. Furthermore, agriculture gains a lot through microwave drying since it reduces moisture content in crops, prolonging shelf life and lowering the chances of mold or bacterial infection. Finally, pet food manufacturers use this technique so that wet ingredients can be defrosted and dried faster, keeping nutritional value intact and preserving product wholesomeness.

The role of microwave systems in food processing

Microwave systems are critical in the food industry because they defrost and dry products evenly and quickly. They save much time during processing compared to traditional methods, which helps maintain food’s nutritional value, texture, and taste. When it comes to thawing with microwaves, there is an even distribution of heat throughout the product, leading to reduced chances of bacteria multiplying, hence less spoilage. In drying processes, this same principle applies where foodstuff moisture content is rapidly removed using microwaves, thereby prolonging shelf life and keeping off microbial attacks. Food manufacturers can achieve higher volume when they integrate microwave systems into their operations alongside better quality control measures, thus ensuring consistent output while improving safety standards.

Use in meat thawing and frozen food industries.

Because they can heat things fast and evenly, microwave systems are great for thawing meat and the frozen food industry. This method ensures that defrosting is done uniformly, keeping the meat texture intact while decreasing the chances of part-cooking, which happens more often when other techniques are used. It also saves a lot of time compared to traditional methods, as microwaving only takes minutes or even seconds, reducing bacterial growth rates that occur during lengthy processes required by some recipes to maintain freshness. Microwaves help businesses dealing with frozen food increase efficiency by quickening up the process, enabling them to meet demand quantities within short periods and ensuring timely delivery, especially during peak seasons when large volumes need to be processed quickly without compromising quality standards.

Expanding applications in tunnel microwave systems

Versatility and efficiency are reasons tunnel microwave systems have been used outside the food industry. Pharmaceuticals dry heat-sensitive compounds uniformly while saving active ingredients from degradation. They also make advanced ceramics and other materials by quickly heating them evenly, thus enhancing the quality and consistency of final products. Textiles benefit, too; drying or fixing dyes with tunnel microwaves saves time in production and improves color fastness. As technology advances, more uses will be discovered which only underscores how vital these machines can be for streamlining operations across various sectors of the economy.

Frequently Asked Questions (FAQs)

Q: What is an Automatic Microwave Thawing and Drying System?

A: An Automatic Microwave Thawing and Drying System is a specialized food machine that uses microwave technology to defrost and dry food products quickly and uniformly. It is widely used in the food processing industry for its efficiency and effectiveness.

Q: How does a microwave tunnel dryer work?

A: A microwave tunnel dryer uses microwave power to generate heat, which is then evenly applied to the product moving through the tunnel. This process ensures efficient and uniform drying of food products, reducing processing time and enhancing quality.

Q: What are the benefits of using a defrost machine with microwave technology?

A: The benefits of using a defrost machine with microwave technology include faster thawing times, uniform thawing, reduced energy consumption, and improved preservation of the product’s texture and nutritional value.

Q: What types of food can be processed with a commercial microwave defrost machine?

A: A commercial microwave defrost machine can process foods, including meats, seafood, poultry, vegetables, and fruits. It is particularly effective for products that need quick thawing and uniform heating.

Q: What is continuous tunnel honeysuckle flower drying?

A: Continuous tunnel honeysuckle flower drying is a drying process where honeysuckle flowers are continuously fed into a tunnel honeysuckle flower drying dehydrator machine. Microwave heating quickly and uniformly dries the flowers, preserving their color and medicinal properties.

Q: How does PLC control industrial equipment improve the thawing process?

A: PLC (Programmable Logic Controller) control industrial equipment improves the thawing process by providing precise control over the microwave power and thawing time, ensuring consistent and uniform results while reducing the risk of over- or under-thawing.

Q: What makes a fully automatic industrial continuous thawing system efficient?

A: A fully automatic industrial continuous thawing system is efficient due to its automated operation, which minimizes manual intervention, ensures consistent processing, and enhances throughput. Its design allows for constant input and output, significantly reducing processing time.

Q: How does microwave heating in thawing equipment benefit the food industry?

A: Microwave heating in thawing equipment benefits the food industry by reducing thawing time, improving energy efficiency, and maintaining food quality. It allows for quicker response times in food processing, leading to fresher products reaching the market faster.

Q: Can a microwave dryer machine be used for applications other than food processing?

A: Yes, a microwave dryer machine can be used for other applications, such as drying chemicals, pharmaceuticals, and other industrial products. Its ability to quickly and uniformly dry materials makes it versatile for various industrial uses.

Q: Where can I find reliable thawing equipment generation?

A: A reliable generation of thawing equipment can be found from reputable manufacturers like Shandong Loyal Industrial Co., which offers a range of industrial defrosting equipment designed to meet the needs of the food processing industry.